This page provides information on monolithic reinforced concrete foundations . We will consider tape, plate and columnar bases, examine their structure, advantages and disadvantages, design features and self-assembly technology.

Monolithic foundation foundation, is a single piece made of reinforced concrete. Such structures have a large bearing capacity and are equipped in the case of erecting buildings that have a significant mass.

There are several types of monolithic foundations:

Installation of a monolithic foundation

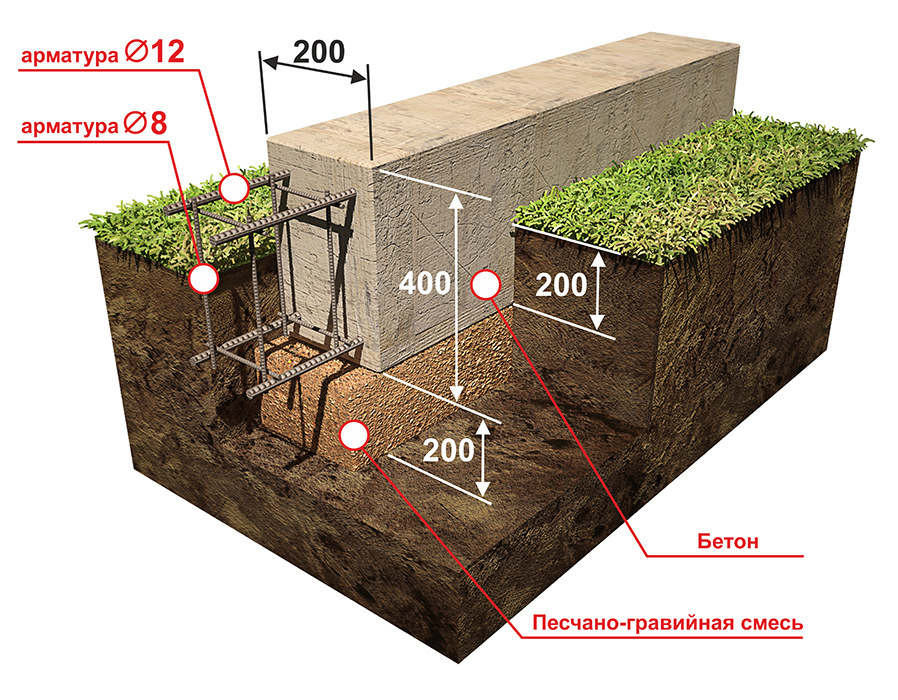

Any monolithic foundation consists of two elements - reinforcing cage and concrete body. After hardening, the reinforcement and concrete work as a single structure, perceiving and redistributing all the loads acting on the foundation.Reinforcement is a prerequisite for the arrangement of all monolithic foundations. The need for it is due to the low resistance of concrete to bending loads (such deformations the base undergoes under the influence of ejecting shearing forces), because of which there may be a cracking of the structure. The concrete itself effectively works on the compressive loads that it receives from the mass of the building.

Rice

Important: reinforcement of monolithic foundations is always performed in two longitudinal contours - along the upper and lower sides of the structure. There is no reason to lay a belt in the middle of the RC, since this part is not affected by strong loads.

The choice of the size of reinforcing bars depends on the dimensions of the foundation. According to the provisions of SNiP, corrugated rods of hot-rolled type A1-A3, diameter from 12 to 18 mm, should be used for reinforcement. To join the longitudinal carcass belts a smooth reinforcement of 8-12 mm diameter is used, which is bent into rectangular clamps.

Rice

The concrete body of the base is formed from concrete of mark M200 and M300. No less important factor is the type of aggregate mixture - it is recommended to use granite crushed stone with a size of 10-20 mm fraction. with flakiness up to 10%. The strength class is M800 and higher. As a filler, you can not use secondary and limestone crushed stone, because of their low mechanical strength, and smooth gravel - since it does not have sufficient adhesion to the concrete solution.

To the concreting of the monolithic foundation, the requirements for the rates of production are put forward - the foundation must be concreted so that the already filled layers do not have time to grasp until the moment of pouring a new portion of concrete. Otherwise, a network of microcracks is formed between the layers, which adversely affects the final strength of the structure. If possible, concreting the foundation must be carried out at the same time, with the use of ready-mixed concrete, ordered in the required volume.

Monolithic columnar foundation

The choice of the type of construction depends on the nature of the structure and features of the soil. Monolithic columnar foundations They are used in the case of erection of panel or frame structures on sand and peat soils. Work on the arrangement of such a foundation is carried out in several stages:- drilling of the wells - it is required to lower the posts 25 cm below the freezing level of the soil;

- immersion of asbestos-cement pipes in the well - fixation is carried out with the help of soil;

- laying in the hole reinforcement, poured concrete;

- tamping the concrete mix with steel rod - the air is expelled from the mixture;

- a set of structural strength - occurs within 2 days.

Ribbon monolithic base

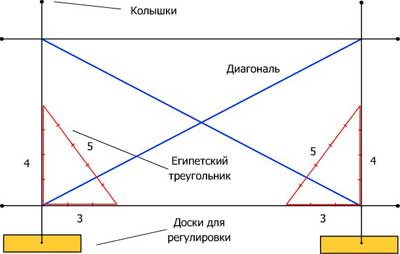

Monolithic strip foundation are manufactured using standard technology:- marking - along the perimeter and along the diagonal the cord is stretched, by means of which the rectangularity of the base is established;

- trench digging;

- casing installation - wooden boards are installed, supported by struts and fastened with bars;

- pouring the base with a concrete mixture - is carried out simultaneously with reinforcement, which is expressed in fixing rods on the formwork, covered with a layer of mortar being subjected to ramming.

Attention!! It is allowed to fill in layers, by filling a third of the height of the formwork and continuing the work, after the concrete mixture has been set with the required level of strength. Installation of reinforcing bars, located overlapping and bending, is carried out. The ramming process is performed using a vibrating platform.

Classical solid plate is in demand in conditions of sandy soils, characterized by constant shattering, ripeness and high location of groundwater. Such bases sustain dynamic movements of the soil, rising and falling with the building during thawing and freezing of the soil.

Recessed monolithic slab

Monolithic recessed slab is equipped according to standard technology:- cleaning of the territory and marking;

- preparation of excavation - extraction of soil at the required depth, with subsequent leveling of the walls and embankment on the bottom surface of the gravel-sand cushion formed layer by layer;

- shaping drainage system - Special ditches covered with geological textiles are made. Above sand and gravel pillow fit waterproofing layer in the form of a polyethylene film;

- creation of formwork - wooden boards with perpendicular angles are strictly installed vertically;

- arrangement of the reinforcing skeleton with the subsequent pouring of the construction with concrete mortar.

Calculation of a monolithic foundation

The purpose of calculating monolithic foundations is to collect the aggregate loads acting on the foundation, and determine the required base area, based on their size and soil characteristics at the construction site.Important: aggregate load on the foundation is the sum of the load from the mass of the house, snow pressure and useful operating loads multiplied by a safety factor of 1.2.

The algorithm for calculating the monolithic base is as follows:

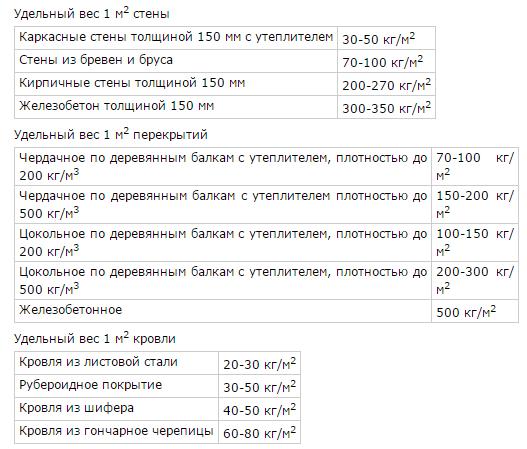

- The mass of the building is being calculated - the area of walls, ceilings and roofing should be multiplied by the specific weight of one square meter of building material from which they are made.

Rice

For example ( cottage with a wall height of 2.4 m, an area of 7 * 7 m with inner wall length 7 m): determine the total length of the walls (7 * 4) +7 = 35 m and their area 35 * 2.4 = 84 m2. We calculate the area of the basement overlap: 7 * 7 = 49 m, the attic floor area will be similar. Determine the area of the roof (taking into account that it stands for the contours of the walls at 50 cm on each side) - 8 * 8 = 64 m2. It remains only to multiply the received dimensions by tabular data.

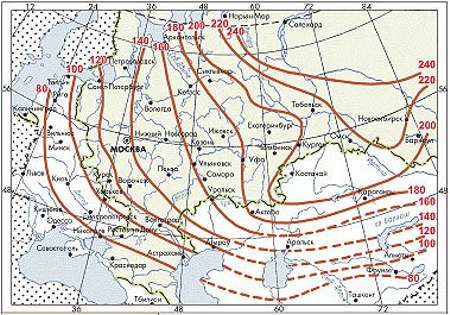

- The amount of snow loads is calculated - the area of the roof is multiplied by the average weight of the snow cover in a particular region;

Rice

- Determine the operational load. The average value of which for residential buildings is 100 kg / m2 of overlap (taking into account the basement and inter-floor overlap);

- Summarize the collected loads and multiply them by a reliability factor of 1.2;

- Define basement depth ;

Important: in soils prone to frost heaving, the foundation foot of the foundation should be laid 20-30 cm below the freezing level of the soil. In shallow soil, finely buried foundations can be used with a depth of up to 80 cm). To the obtained depth, 30-40 cm is added to the basement part of the basement, which gives the total height of the base.

Rice

- Determine the base area of the foundation.

It remains to calculate the total load on the ground (the weight of the foundation + the value of previously defined loads from the mass of the building and the snow cover) and divide them into the base area of the basement. As a result, we get the building pressure per cm2 of soil, which should be compared with carrying capacity of soil on the object.

The most accurate information on the characteristics of the soil can be obtained by running on the site geodetic survey . If this is impossible, use the table of the average carrying capacity of the soil.

Rice

Important: if the calculations showed that the load on the soil is within the norm, this foundation is suitable for construction. In case of exceeding the load, it is necessary to increase the base area of the base (its width) and recalculate.

Monolithic foundation by one's own hands, technology

The algorithm for constructing the foundations of band, plate and columnar types is given in the previous sections of the article. We will consider critical errors at the main stages of monolithic base installation, which are unacceptable.- Layout of the foundation before work;

Rice

It is extremely important to check the correctness of the right angles of marking, both on the inner and outer zones of the basement. This is done according to the rule of the Egyptian triangle - in the angular part of the base, from the point of intersection of the cord, 3 and 4 m are retreated and appropriate notations are made (pieces of electrical tape are attached to the twine). The distance between the marks is measured, if the right angle is correct, the length of the diagonal should be 5 m.

- Installation of formwork and a sealing pillow.

When assembling the formwork it is necessary to strengthen the lateral braces and transverse bridges connecting the side shields along the upper contour to prevent deformation of the mold under the weight of concrete.

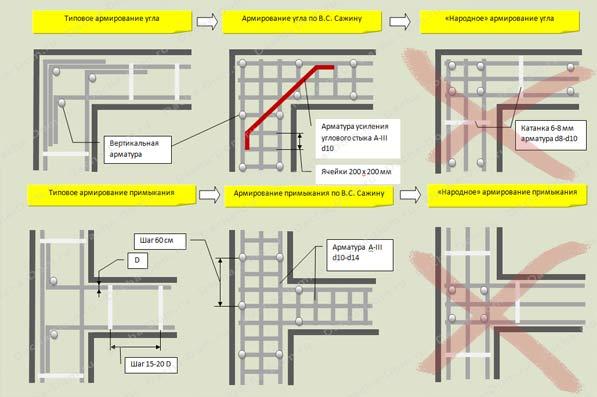

A typical error in the reinforcement of monolithic foundations is the incorrect joining of the corners of the frame, to which basic loads fall during the operation of the foundation.

Important: widespread cross reinforcement is unacceptable, it is necessary to connect the corners by means of curved L-shaped rods or according to VS Sazhin's recommendations - by reinforcing additional rods.

Rice

- Pouring and holding concrete.

Important: if the foundation is gaining strength in the summer, at temperatures above 20 degrees, the concrete must be moistened daily from a hose with a spray nozzle, as when drying on the concrete, microcracks can form.

Advantages of monolithic foundations

Monolithic foundation plates, have a number of advantages:

- high level of strength in the horizontal and vertical plane; on the ground is distributed evenly;

- guarantee of unharmedness buildings in the case of mobile soils;

- bedding level groundwater irrelevant;

- increased load bearing capacity;

- tightness and durability - the structure of the structure preserves its integrity.

Cost and calculation of a solid foundation for the house

The only drawback is the high cost of the base, which consists of the following factors:

- dimensions - length, width;

- depth of excavation;

- preparation: sand, concrete, crushed stone;

- reinforcement , concreting.

Monolithic foundations - this is a type of structure, which is made by pouring a concrete mixture into the formwork, previously reinforced with reinforcement. The result is a sturdy construction that can withstand both compression and tensile stresses. Due to this, a monolithic reinforced concrete foundation allows the construction of a two-story and even multi-storey building.

Monolithic foundation is poured directly on the construction site with their own hands, representing a holistic structure. It has no seams, if you take as an example - a prefabricated foundation of FBS. Due to this, considerable durability is achieved foundation plate.

Advantages and disadvantages of monolithic foundations

Monolithic foundation has its advantages and disadvantages, which will allow you to better navigate the construction market, and most importantly - choose which reinforced concrete foundation is best suited for your purposes.

- the monolithic foundation is characterized by increased strength and the ability to withstand various types of loads. These pluses allow you to build a house on the heaving ground;

- the technology of manufacturing such bases makes it possible to build much faster with their own hands than the bases from FBS;

- a monolithic slab can be made of very different configurations, which is especially important when building a building with a nonstandard base form;

- reinforced concrete foundation has good waterproofing characteristics, if the thickness of insulation is correctly calculated;

- for manufacturing there is no need to use expensive lifting equipment, due to which the construction comes out somewhat cheaper;

- reviews of builders say that the technology is simple, properly pour a monolithic plate with their own hands can even low-skilled workers;

- the reinforced concrete foundation acts as a pillow, which protects the basement and the cellar from external factors.

- weak thermal insulation properties. If we calculate the thermal conductivity of concrete, we can see that the reinforcement creates "cold bridges", these are the minuses for the ability of the structure to keep the set temperature;

- high manufacturing cost. The price of works only over the construction of the foundation can reach the third cost of the entire building. FBS in this regard will cost much cheaper.

Varieties of monolithic foundations

The monolithic foundation can be made in 3 ways, which one is better to choose - depends on the purpose of construction:

- tape;

- plate;

- columnar.

Tape monolithic foundation is placed along the perimeter of the house, and also as a foundation for the walls. This is the most popular type of foundation in order to build a cottage or a private house two-story type with their own hands.

It provides for the possibility of a semi-basement device that can play the role of a garage or a technical floor, as the modern cottage needs so much. The technology of such a foundation with proper operation requires the installation of a sand and gravel cushion.

The pillar foundation is not as reliable and durable as its counterparts, but its construction will cost you significantly cheaper. The columns are concentrated at the points of calculation of the greatest load on the base, as well as on walls whose thickness is less than the standard one.

The device of the plate foundation occurs under the entire area of the house. Thanks to its large footprint, it can withstand heavy loads and instability of the soil.

The main ability foundation plate is the ability to move along with the soil, because monolithic basement foundation also called "floating". But such a foundation can not be arranged on a slope and in places that are prone to flooding - because of the low height, such a base will simultaneously serve both the floor and the building.

Technology of plate foundation construction

Before starting the work, the first task is to calculate the future design. For this, it is necessary to take into account the type of soil, the depth of its freezing, the height of the location of groundwater and the climatic features of the region.

All this can be entrusted to professionals, but the cost of such work can scare away novice builders. Therefore, most often the calculation of the foundation plate is done by oneself, since a large margin of strength of the plate allows for small errors.

In addition to the ground, the calculation also requires a pillow, that is, the sole of the foundation slab. If the soil is puchinisty with a high depth of freezing, then the pillow is made according to the maximum area base, evenly distributing the load on the ground.

When building on abrasive soil with low HPG, it should be borne in mind that the pillow will be located below the depth of freezing. If the soil has a small abrasion, the cushion is installed at any height.

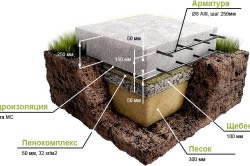

Directly the technology of the device of the slab base with own hands contains the following stages:

- Firstly, the calculation and marking of the plot under the foundation is carried out. The unevenness is checked by the level and the building level. The area of construction should be several meters larger than the area of the future house.

- Then, the pit is pulled out by oneself or with the help of construction vehicles. Ensure that the bottom is horizontal.

- A sand cushion is created to improve the stability of the plate. The sole requires obligatory tamping with the use of a vibratory plate

- The next stage is the installation of communications, as an example - sewerage, drainage system and water pipes.

- Before the main layer is poured, the concrete preparation. It consists in pouring a layer of concrete screed, the thickness of which is 10 centimeters, using a cement mortar M100. A bituminous primer is applied to the substrate.

- how foundation monolithic plate is covered with waterproofing, the seams of which can be joined by a blowtorch.

- Mounted formwork along the perimeter of the structure.

- The calculation and installation of the reinforcing cage, the diameter of the reinforcement from 12 to 16 millimeters is carried out. The grid cells should be about 20 × 20 centimeters.

- Filling the slab with concrete of the selected brand and sealing with a deep vibrator. After hardening of the concrete mix, the formwork can be removed. Full strength monolithic plate gets 28 days after pouring.

Warming of a solid foundation plate

Features of this type of foundation, such as a monolithic slab, require its additional insulation.

This solution will help reduce heat loss through the slab, and also reduce the subsidence of the soil beneath it. The problem of thermal insulation of the foundation is to think about the inhabitants of severe climatic regions, as well as those who have houses or a cottage on the ground where the thickness of the ground is above average freezing.

Thermal insulation of the base plate is possible both from the outside and from the inside. In case of external insulation, in order to keep the freezing point in the non-sooty soil, insulation of the ground is made under the pavement on the perimeter of the house. The technology of thermal insulation with expanded polystyrene requires the calculation of the given slope of the blind area, for example - about 2% of the base of the house. The thickness of the thermal insulation horizontally must be at least not less than the vertical dimensions of the insulation materials.

If external insulation of the foundation is not possible, the technology of thermal insulation inside is applied. In this case, the extruded polystyrene is laid from the side of the walls. Fastening of the material is carried out either on a cement basis, or mechanically fixed with subsequent finishing.

Technology of the monolithic foundation (video)

Comparison of monolithic and block foundations

FBS prefabricated type are manufactured at the enterprise and delivered to finished form on the building site. The human factor, when using production capacities, is minimized when the calculation of a whole monolithic foundation depends only on the person.

In addition, the prefabricated foundation FBS does not depend on weather conditions, since production is conducted in a closed shop. Plans to manufacture a monolithic base with their own hands can interrupt normal rain.

On the other hand, when choosing FBS, it is necessary to take into account the supply of concrete blocks, the distance of the enterprise to the construction site.

FBS is not flexible in the field of application in construction, and is used primarily for unified buildings.

Summing up, if you are planning to build a house with a unique appearance, non-standard forms, then it is worth paying attention to a monolithic reinforced concrete base. The typified prefabricated FBS is very narrow in application.

But prefabricated reinforced concrete is very good for small buildings, the costs for which do not pay off in a monolithic construction. FBS allows you to build an inexpensive small object in a short time, and a monolithic foundation is suitable for building a large shopping center, or as an example, with its help you can build a large cottage.

Back to contents

Principles of the construction of foundation slabs of buildings and structures

Most often in the construction of houses used foundation slabs. The base of these materials is a structure with high reliability. Foundation plates can be prefabricated and monolithic.

A monolithic base can be used not only for the purpose of building a private sector, but also for large facilities that require the erection of a monolithic foundation. is associated with the manufacture of the base of the structure, performed with the use of solid reinforced concrete.

The technology of building a monolithic foundation of reinforced concrete is not only simple, but also allowing to guarantee the reliability and durability of the entire structure of the base of a building or structure. Cope with the construction of the foundation slab can be independently without assistance.

The construction of a foundation on the basis of monolithic slabs has recently become widespread. The diagram (PICTURE 1) shows the types of grounds of a building or structure that can be used during construction.

There are two types of monolithic foundation:

- Plain.

- Reinforced (reinforced concrete).

At the device of the simple basis use concrete of mark 50 and above. Sometimes stones are used in the construction of its construction for the house. In this case, concrete is obtained, in which the mass of stones is 30 to 40% of the mass of concrete as a whole. The concrete itself is called butobetone, which, in its strength, is not inferior to ordinary concrete. The use of stone in the process of building monolithic bases can reduce cement costs, due to which the cost of construction is reduced.

Starting to pour concrete, prepare boards for which is of two types:

- Removable.

- Fixed.

Instead of formwork, sometimes use inventory boards or simply the walls of the pit, for which waterproofing is specially carried out with the help of ruberoid or polyvinyl chloride films. Otherwise, the cement "milk" will be absorbed into the ground, which will cause a reduction in the strength of the entire structure.

Building a house is always a very important event, especially if it is decided to do without attracting specialists. In this case, the probability of errors is high due to lack of experience, and therefore, before beginning the work, it is necessary to study all the subtleties of each stage.

Any construction begins with a foundation, and therefore it is necessary to start first of all to master the process of its creation. The most reliable of all the bases is the slab foundation, however, the technology of its erection is not the simplest. In the event that a decision is made to equip it with its own resources, it is necessary to become fully acquainted with the process and find out in advance what mistakes are most often tolerated in the construction of such a basis.

Without this, in the absence of the necessary building experience, there is a great risk of making a foundation that will not be able to withstand the weight of the building, which will require urgent repairs or replacement of the base.

Classic slab foundation

When a monolithic slab foundation is under construction, it is important to perform the work in strict sequence, not missing a single stage. Any inaccuracy in the construction will lead to disastrous consequences. If you divide the entire process into stages, then there will be several:

- . the marking of the plot;

- . excavation;

- . preparation for pouring;

- . pouring concrete.

The most laborious part in this business is preparing for pouring. The technology of the plate foundation requires different works at this stage.

At the very beginning the plot is marked out, guided by the plan drawn up in advance. Then dig a pit. Do it faster and easier with the help of an excavator, but if this is not possible, then you can dig a foundation pit yourself, but only, of course, not alone. Once it is dug, you can go to the preparation stage for the fill.

To begin with, a sand cushion is arranged on the bottom, which is carefully compacted. Usually enough of its thickness is twenty centimeters. The best option is a sand and gravel pillow. Its surface is poured concrete screed thickness of ten centimeters. Further work continues only after the concrete has completely hardened.

Then waterproofing is carried out, for which the roll material is used. When it is spread, they pass to the installation of reinforcement. The technology of construction of a slab foundation requires the use of rods with a diameter of ten to twelve millimeters. For the reinforcing cage, in this case, it is not necessary to use the binding wire and you can use welding.

![]()

After the reinforcement work is completed, the formwork is assembled. Her type is chosen at will. When the formwork is ready - pour concrete. At this time it is important to prevent the formation of voids, which in the future will reduce the quality of the foundation of the house.

Tape foundation and slab

It is not always possible and necessary to build a classical base monolithic slab. In some cases, a more convenient option is the ribbon-slab foundation, the technology of construction of which is also required to know.

The first variant of such a foundation is the pouring of a monolithic slab inside ribbon foundation. In this case, the work will not be practically different from the filling of the classical plate.

Another option is the one where the strip foundation is built using reinforced concrete slabs. In this case, the foundation is not monolithic, but a composite. Apply for a strip foundation in this case most often reinforced concrete slabs, corresponding to GOST 13580 85. Manufactured in the factory, they will not present unpleasant surprises during operation.

The merit of such a foundation is that it will not be necessary to expect hardening of concrete, and consequently it will be possible to proceed much more quickly to the construction of the house. The main thing in the construction is not to save on the plates and not to purchase the material of inadequate quality.

How to calculate the thickness?

Starting to build a monolithic base plate, it is necessary not only to competently conduct all the work, but also correctly calculate its thickness. If this is not done, then the foundation, not having coped with the weight of the building, will be damaged, which will lead to damage to the entire structure. Without calculating the thickness of the foundation slab you can build only if it is known to be made very powerful, but it will be quite expensive, because construction Materials not cheap.

In order to know exactly what the cooker should be, it is convenient to refer to specialists who, using all the formulas necessary for this and complicated formulas for people not involved in such calculations, will choose the optimal variant. Of course, these services will require additional costs.

However, you can make all the calculations of the thickness of the foundation of the plate and yourself using a special calculator. With this option, the result will not be absolutely accurate, but sufficient for construction a country house from not the heaviest materials. Taking this into account, it is undesirable to calculate the foundation thickness of a monolithic slab yourself when building very heavy structures. In this situation, the appeal to specialists is mandatory.

A qualitatively manufactured slab foundation will ensure the construction of a solid foundation for many years, without the need for repair and especially replacement. Given this, in the process of building the foundation, it is unacceptable to save on the materials and the help of professionals. The fact is that money saved by improper actions or by the use of substandard materials will later be required for repairs, which will be much more expensive than conscientious construction.