What kind of foundation you will build, so much a house and it will stand. Therefore, take your choice seriously, to guarantee the construction of a long life. Monolithic foundation is suitable for construction on problem soils, since there are no weak joints in the structure, as in prefabricated bases.

There are 3 types of base made of monolithic concrete. The choice depends on the weight of the structure, the type of soil and your budget. Pour the monolithic foundation with their own hands is not so difficult, especially a shallow band and slab.

1. Tape.

Underneath all the bearing walls of the future construction, a strip of concrete is made. It can be shallow (30 -70 cm) and recessed (1 m or more). With a high level of groundwater in clay soils, it is essential to deepen the foundation below the freezing line of the soil, strengthen and isolate it from water. This is the best variant of the basement of the house with a basement.

![]()

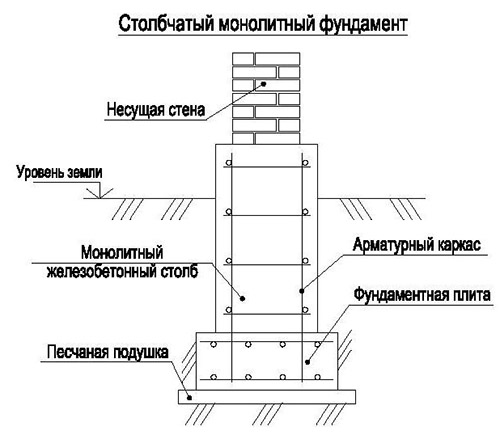

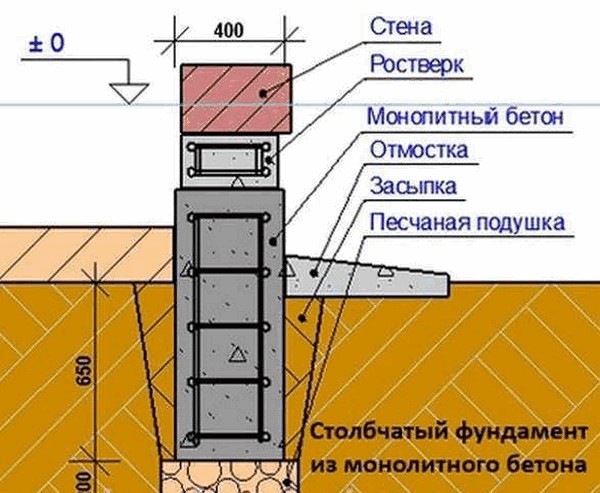

2. Columnar.

The most inexpensive, the entire foundation - the pillars at a distance of 1-2 m. Suitable only for one-story light buildings on fixed soils. Sometimes this technology is combined with a tape to make a small basement.

3. Plate.

The foundation plate is easy to calculate and fill. Just like the tape, such a foundation is not deep and deep. The first option allows you to save significantly on the amount of land work, but does not allow to equip the premises under the house. But you will immediately have a rough floor. The second type is suitable for a heavy structure, in addition, there you can make a basement. But the cost of such a plate is high.

When it is advisable to use:

- Problem soils.

- For houses from heavy materials (concrete, brick, stone).

- For buildings on flat terrain.

Step-by-step instruction

Suppose you have already carried out all the necessary calculations, having carried out an examination of the soil and having calculated the weight of the house, and drew a diagram of the future foundation. Technology monolithic plate foundation simple, so if you want to just fill it yourself.

1. We will outline the area of the future house according to the scheme.

2. Remove the primer and level the surface. The optimum thickness of the monolithic slab is 20-40 cm, depending on the soil and the overall weight of the structure.

3. We fall asleep sand, well we compact. To do this, it is better to moisten it, if possible, use a plate compactor for ramming. Then fall asleep rubble, the thickness of each layer - 10-15 cm, depending on the availability concrete preparation and soil characteristics.

5. We will erect concrete preparation. Lay the film on the surface, so that the liquid does not go into the sand, Usually use the brand M50-M100. The thickness is 5-10 cm.

4. Mount the necessary parts of the water supply and sewerage. It is better to install boxes above the pipes, this will protect the structure from destruction.

6. Put the materials for waterproofing. Their size should slightly exceed the area of the future foundation plate, and all the seams need to be soldered.

7. We lay down the layer of thermal insulation.

8. Mount the reinforcement.

9. We install the formwork.

10. Fill the concrete and compact it. It is more convenient to use a vibrating packer to distribute the concrete evenly and quickly over the entire formwork.

11. Cover with a protective diaper. We are waiting for 3-4 weeks, until the concrete will gain sufficient strength for further work.

1. Why do we need stiffeners?

The stove is not always flat. For heavy structures and problem soils, stiffeners are installed under the bearing walls. Most often they are rectangular or they decrease to the bottom. This design increases strength. The ribs placed above the slab make it possible to create a technical basement of a small size, which will simplify the communication in the house. But then the surface of the monolithic foundation slab will no longer be the rough floor.

2. What is waterproofed?

Polyethylene film with a thickness of 200 microns or roofing material. There are special materials for concrete, for example, Delta MS. It perfectly isolates from water, and if the UGW is small, it can play the role of concrete preparation. Also geotextiles are used for this purpose.

3. Is it necessary to insulate a monolithic structure?

Yes. Concrete conducts heat well, and a large amount of reinforcement creates bridges of cold. Common insulation - polystyrene foam and polystyrene foam.

4. Do I need to drain?

Unambiguously needed, if the site is high HGV. It is important to observe the slopes of the pipes, provide a place for the removal of water, make wells, so that in case of siltation of pipes they can be cleaned. Drainage is usually placed in a geotextile on a sand and gravel pillow.

5. How and from what to build a timbering?

We recommend using laminated plywood. It will be easy to remove such formwork. If you make it from ordinary boards, plan them where they will touch the concrete. In the formwork there should be no slots, and its strength is checked by kicking. There are many mixtures that lubricate the formwork to make it easier to remove it, for this purpose you can fix the film on it. Fasten the formwork better with self-tapping screws, not with nails.

6. How to reinforce correctly?

For a slab of 20-40 cm, 2 layers of reinforcement are sufficient. The horizontal distance should not exceed 20-30 cm. The distance to the boundaries of the concrete slab is 15-20 cm. For binding, the armature is connected with a wire. Monolithic reinforced concrete foundation will withstand the load of a two-three-story house made of concrete, brick, stone. For reinforcing bars suitable for diameters of 10-16 mm, depending on the weight of the house.

7. What can you save on?

If you plan to equip a porch or a large terrace, make a strip foundation there, so as not to waste concrete, since the load on this part will be several times less.

Major mistakes in construction

1. Wrong care. According to the instruction, concrete needs 28 days for a set of brand strength. Especially important are the first days, if dry and sunny weather is, cover the concrete with a tent and water it with water. The optimum temperature for hardening + 15-20 degrees.

2. Low brand. For the construction of a monolithic base, concrete above M200 is required, and if the ground is problematic, it is higher than the M300.

3. Weak formwork. A weak structure will expand under the pressure of the mixture, because of this concrete is not enough. Such an error can not be corrected, the ground will have to be demolished and rebuilt, as it is obligatory to fill everything in one go. If you decide to build yourself, it's better to show the formwork to a specialist.

4. Insufficient heat and waterproofing. High brand and strong reinforcement will not save from cracks, especially for the foundation in the flooded areas, and heating costs will negate the savings in thermal insulation.

5. Wrong reinforcement. Bind the rods to overlap each other by 10-20 cm depending on the diameter. In a monolithic reinforced concrete structure, reinforcement prevents stretching, and concrete - compression, so strength is achieved by a harmonious combination of components.

6. Porch. It happens that developers forget about the porch. But it is better to do it immediately, so that when shrinking into the soil, the house and the porch do not part.

If you decide to build on your own, make the calculations in advance and draw a diagram to choose the correct type. There is no universal monolithic construction, suitable for any case. Follow the technology of building the foundation step by step, so as not to correct their mistakes.

Monolithic foundation is one of the most expensive types of basement under the house. But on some soils it is the only suitable option. Also it is made in the construction of multi-storey houses, when a particularly solid foundation is required. The article will deal with all aspects of filling monolithic foundation.

Advantages and disadvantages of a monolithic foundation

Reliability and high load-bearing capacity make it possible to install it in any type of construction. Specifications are fundamental when choosing a monolithic slab foundation for the construction. Below, we consider the most significant advantages.

- Absence of stitches. It is their absence in the design of the plate is considered the main advantage. This parameter provides a monolithic foundation of high strength even when moving the ground.

- Speed of installation. Since it is carried out by a single area, the time is significantly saved on the formwork. And in the presence of construction equipment - an excavator, a mixer and a plate compactor, the work is carried out for a couple of days. The most prolonged process will be the knitting of reinforcement, which will require significantly more than with other types of foundations.

- Arbitrary configuration. Therefore, it will be an excellent option when the house has non-standard forms, for example, decorated with bay windows.

- Waterproofing. Due to the integrity of the structure, the water does not penetrate into the basement and does not destroy the base of the house. Monolithic slab is recommended to be flooded in wetlands or at a very high level of groundwater.

The disadvantages include the high price of pouring a monolithic foundation. In turn, it consists of a number of parameters:

- a large amount of concrete is required, and it must be filled at a time. And this means that you will have to order several mixers at a time;

- you can not do without hiring construction equipment or renting expensive construction tools;

- another point is associated with low thermal insulation properties. The foundation itself consists of concrete and metal wire, which only give off heat, without holding it for long. Correct it with the help of plate heat-insulating materials laid throughout the base area;

- impossibility to equip the basement. The only exception is the house on several floors, in this case the stove will become a floor in the basement, and under the basement there is a ground floor.

Types and applications of monolithic foundations

There are three types of monolithic foundations.

- Tape. It is a reinforced concrete tape, arranged along the perimeter of the building and under the bearing walls. Suitable for construction on soils with medium bearing capacity.

- Plate. Unlike the first species, it is poured in the form of pita, under the entire area of the structure. Applied in seismically dangerous places and on weak ground, which can move when changing seasons.

- Pile-grating. It looks in the form of concrete pillars buried below the freezing level and bound along the perimeter by a reinforced concrete grillage.

The depth of penetration into the ground is divided into:

- shallow monolithic foundation. In this case, the tiles are mounted no deeper than 500 mm. It should be borne in mind that the ground beneath it freezes, so you need to make a thick sand cushion;

- to the depth of freezing. It is done in the construction of multi-storey buildings. The plate is poured below the freezing level, and this is not less than 1500 mm for the central strip of Russia. This will require long and costly excavation, but the result will be a solid foundation with the possibility of equipping the basement.

The cost of a solid foundation plate

When calculating the cost, one must rely on objective prices building materials in each region. For example, let's take into account the following values:

- pouring a monolithic foundation 30 cm thick;

- the order of a mixer with concrete, the price for a cube of a solution of 3500 rbl .;

- reinforcement for binding. It varies in diameter, but the average price goes for a ton and is about 25 tr. The size of the cells is 20x20 cm;

- all the work on pouring the foundation is done independently, without hiring workers.

Thus, the cost price of a 10X10m slab will be 120 tr.

Pouring the monolithic base photo

Preparing before pouring a monolithic foundation plate

Due to the fact that this type of foundation is used in difficult conditions on mobile soils, it is subject to increased demands. Therefore, if you want to save on the construction team and do all the work yourself, you should not only learn the right technology, but also comply with it at every stage.

- Before the construction of a monolithic reinforced concrete foundation, a plot is prepared for it. The territory is completely cleaned, access roads for large-scale equipment are being prepared.

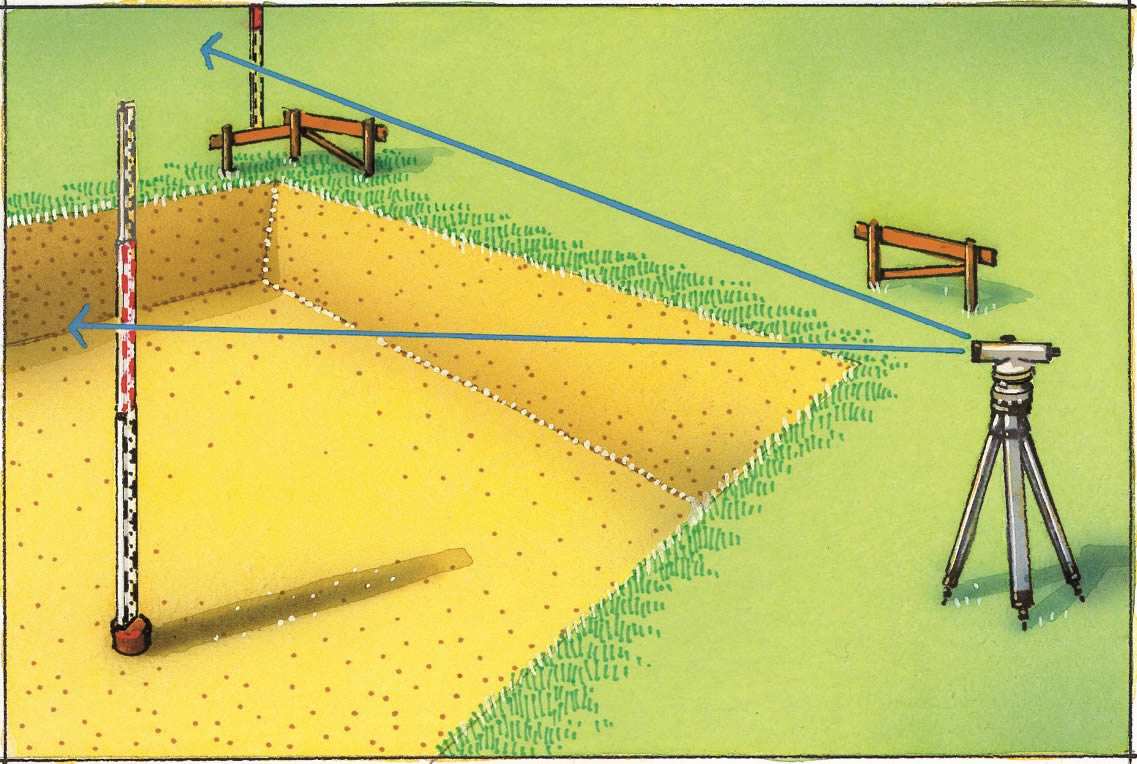

- Then the marking of the future base is carried out and a layer of soil with vegetation is removed over the entire area. At this stage, it is possible to carry out preparatory work and to equip the blind area.

- Then comes one of the most laborious and responsible processes - excavation. Depending on the type of foundation, the depth of occurrence will vary from 500 to 1500 mm, and the width is 1 to 1.5 m larger than the foundation itself. Despite the fact that the concrete mix is plastic and leveled in the horizontal plane independently, the bottom of the excavation should be as flat as possible. This significantly affects the quality and reliability of the foundation. Here you can not do without the services of an excavator. It is desirable that it has a smooth bucket without teeth, which will make a smooth cut without mixing different soil layers with each other and without loosening the surface.

Tip: To determine the depth of the excavation it is recommended to perform preliminary geological exploration. Best of all, if the soil is sandy, then strong burial is not required. The most unstable and mobile soil is clay. Ideally, it is recommended to choose it completely and dig below the freezing level.

Filling technology for a monolithic foundation

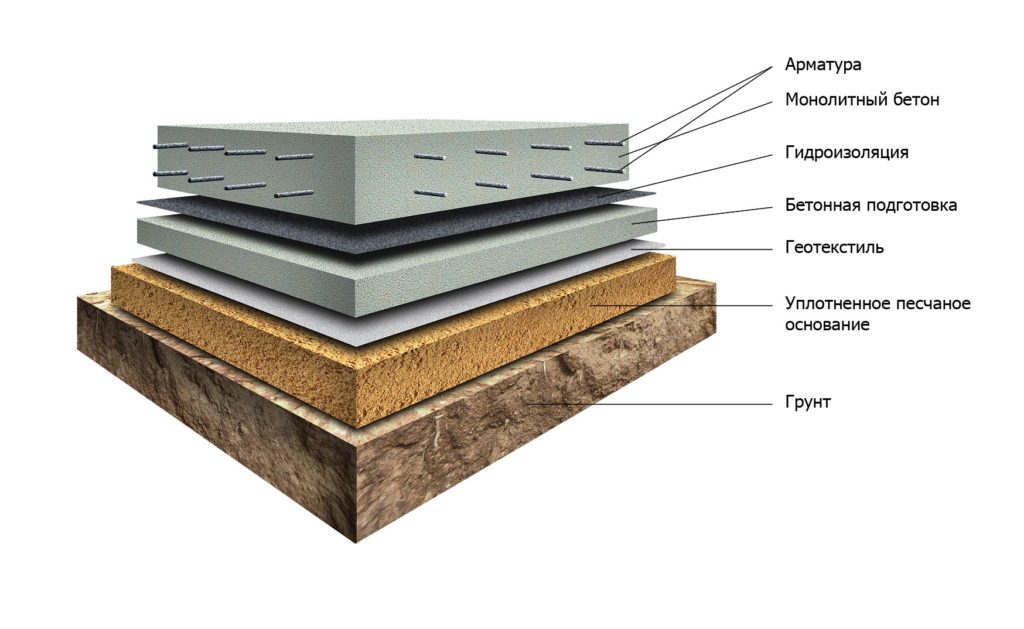

- Now it's time to make a multi-level pillow under a monolithic foundation. For this, the first layer is laid geotextile material, the higher its density, the better. It performs the function of a layer between gravel and sand (or PGS), not allowing the latter to go into the ground. If the thickness of the layer does not exceed 20-30 cm, then sand can be laid over it, if the monolithic foundation is deeply buried, then it is possible to save and start the ASG. After that everything is rammed by a vibration plate until the person can walk on the surface and not fail.

Tip: at the stage of arrangement of the pillow, there should already be provided and laid such communications as sewerage and water supply. So that later it would not be difficult to put them into the house.

- Next is another layer of geotextile, on top of which, this time, rubble crushed with a fraction of 30-40 mm in thickness of 20-30 cm. It is also compacted and trampled.

Tip: At this stage it is important that the level of the surface is strictly in the horizontal plane. This can be done with an optical level. And it is convenient to check the angles with the laser level.

- It was the turn of the waterproofing. It is best to use a roll-on waterproofing material that unfolds over the entire surface with small overlapping strips on each other.

- Then comes the thermal insulation material. Here your choice should be stopped at the penoplex, since it has a greater density than the foam, has better characteristics, does not crumble, and most importantly, it does not gnaw the mouse. In order to exclude possible bridges of cold, the material should be stacked in two layers in a staggered order, in this case you need to buy slabs 50 mm thick.

- If the lower layer is laid over the area of the entire foundation pit, that is, by warming it and protrusions of 1.5 meters, then the top is laid strictly on the size of the foundation. This step allows you to achieve that without gaps, the blind area will be insulated.

- The turn of the form came. It is not worth buying a low grade board, the material must be dried, without rot and visibility (in the future it can be disassembled and used in construction). The thickness of the board directly depends on the foundation, so, for a shallow depth of 25-30 mm thickness, for deeper it will take 50 mm.

- From the material prepared, the shields are built or fastened with screws. To strengthen them every 50-60 cm are screwed with vertical bars. Then they are mounted along the perimeter of the future plate, thus creating a formwork. At the end of the work, we need to check diagonals and angles again. Making sure that everything is done correctly, the formwork is fixed with pegs in steps of 50-80 cm, the corners are fixed and the spacers are placed on the outer side, allowing better to hold the structure when pouring concrete.

- Further reinforcement of the monolithic foundation is done. This time-consuming and crucial moment will affect not only the reliability of the foundation itself, but also the strength of the future home. The type of reinforcement depends on the construction, so for small single-storey houses or garages a reinforcement net with a cell of 10 cm is suitable. When constructing a heavy brick or two-storey house, it is optimal to use a reinforcement with a diameter of 15-20 mm. It is desirable that it has ribs for better adhesion to the concrete mix.

- But here there is a nuance. Obviously, the thicker the armature, the more reliable the base will be and the greater load it will be able to bear. But given that it is knit and fit into several rows, it takes a lot of space and, therefore, the concrete will fit less.

- For example, consider reinforcing bars 16 mm and with a cell size 20x20 cm. Before you start working, you need to arrange a gap between the base and the first row of reinforcement, which should be at least 5 cm. For this, there are special stands on sale.

- To achieve the required strength it will only be obtained when knitting, you can not weld the reinforcement. For this, there are special adaptations from inexpensive household, to serious professional.

- It is best when the reinforcement is laid in one piece, without cutting. That is, with standard size reinforcing bar in 11.7 m, laid in the foundation of a long 10 m, the extra 1.7 meters are cut off. But it is not always possible, for example, when the width of the house is larger or the material was brought in by its car and was shorter than the length. In this case, the reinforcement is knit with an overlap of 10 cm.

- When the first layer is connected and mounted, the next one has come. The permissible distance between them is 20-30 cm. The distance between the reinforcement and the formwork varies within 3-6 cm.

Pouring the foundation with concrete

- When the sand cushion is made, the formwork is assembled and the reinforcement is mounted, the turn of the pouring of the slab with concrete begins.

- At this point, the right amount of solution and its brand should be calculated. We also need to take care of the access roads, since a full loaded mixer weighs a lot, and it will be necessary to approach it close to the formwork.

Advice: when pouring a large volume of solution, it is preferable to order a machine equipped with a concrete pump. With a shallow basement of a small size, an auto mixer with a conventional retractable tray is perfectly suitable.

- Choose concrete, based on its brand, which is responsible for the strength of the composition when hardening. This is due to the fact that the higher the grade of the mixture, the more cement in its composition. Based on SNiP, this parameter for concreting the foundation must not be lower than the M-250.

- As already mentioned above, it is best if concreting is made at a time. If you take a break, the previous pouring will harden and a seam will form at the junction. In the future, in its place is a large probability of a crack.

- When pouring, air bubbles form, which adversely affect the final result. To remove them, the base, if possible, is required to vibrate. After that, the foundation is covered with a film.

- It is possible to disassemble the formwork not earlier than in 7 days, and to start construction and then later. Only after 2 weeks the concrete is gaining its strength.

Filling the monolithic foundation of video

The foundation plate, in contrast to the base of the tape, is a relatively rarely used type of carrier base. The device of the slab foundation is quite simple, but the pouring of the slab requires strict observance of the technologies.

To get a reliable and solid monolithic slab, you need to take into account a number of aspects, as well as make the correct calculation and quality ground preparation.

This article contains step-by-step instruction pouring the foundation slab with your own hands.

Monolithic slab is suitable as a foundation for many soils

Monolithic slab is suitable as a foundation for many soils

Monolithic foundation is a reinforced concrete slab-base on which the building is located. The technology of building such a foundation is not particularly difficult.

Any private developer, even without special skills in the construction craft, can fill the foundation with his own hands.

However, this technology has its own peculiarities and nuances, non-observance of which may cause premature destruction of the base and the entire structure.

Application area

Tape foundation is the best option in most cases

Tape foundation is the best option in most cases The most common type of bearing foundations in private building today is the foundation-tape. It is universal and fairly simple to manufacture. But in some cases, this option may be completely unacceptable. The reason for this, first of all, can be the features of the soil on the construction site.

For example, a high or constantly changing groundwater level, as well as a great depth of soil freezing, will require the construction of a deep foundation. This makes the installation of a monolithic tape-type base economically unprofitable because of the technical complexity of the works and their high estimated cost.

At the same time, pouring a monolithic foundation slab becomes feasible under a number of conditions.

At the same time, pouring a monolithic foundation slab becomes feasible under a number of conditions.

- Work on difficult soils, when it is necessary to evenly distribute the load on as large a base as possible. The technology of the plate foundation allows to increase the area of the support, thereby reducing the specific pressure on the ground.

- The absence of a basement or basement house in the project.

- If necessary, fill the rough floor. In this case, it is possible to use a foundation slab not only as a bearing base, but also as a concrete floor.

When choosing a foundation for a private house, you should carefully analyze all the pros and cons of a particular technology. So, if the developer decided to stop his choice on the base plate, he must figure out whether all the technical conditions of construction are suitable for the slab foundation.

Pros of Technology

The technology of pouring such a foundation is simple, you can do it yourself

The technology of pouring such a foundation is simple, you can do it yourself The foundation of the slab has a number of advantages for the builder, who decided to choose this variant of the bearing foundation for its construction.

Among the main advantages of the tile foundation are the following:

Filling the base-plate

The device of the plate basis

The device of the plate basis Despite the simplicity of the slab foundation, the technology of its construction should be kept as clearly as possible. Before pouring the slab under the foundation, you should familiarize yourself with a number of nuances that will make it possible to get a really high quality and durable basis.

Below are instructions on how to fill in correctly monolithic base plate. If a private developer wants to do all the work himself, step-by-step guide will render him invaluable assistance in this.

Designing

Before making a foundation, it is necessary to make technological calculations and create a draft of the future design on paper.

A construction project is being carried out with maximum consideration of all aspects that may have an impact on the construction and further operation of the base. The mistakes made in the calculations may have the most negative impact on the whole further process of building a house.

Among the main factors that need to be taken into account when drafting a project, it should be specially noted:

- characteristics of the soil: its strength, height of subsoil waters, relief;

- possible external influences on the base: erosion by rainwater, pressure of punching forces, shrinkage of the structure;

- dimensions of the building. The more massive the building will be built on a monolithic slab, the greater the thickness of the slab and the more rationally distributed load across its entire area.

When erecting small buildings, such as a sauna, a garage, an easy holiday cottage, the calculation can be done by eye. Even a small layer of reinforced monolithic concrete will be enough to withstand their weight. But if, on the basis of a slab, a capital housing structure will be built, it is best to seek help from specialists with engineering education.

Due to the complexity of the calculations, it is possible to make mistakes in the design, which will be difficult to correct later on.

Site Preparation

The layout is done on an aligned cleared area

The layout is done on an aligned cleared area This stage of work includes the planning of the site, the excavation and excavation of soil. First of all, it is necessary to clean the construction site of vegetation: cut down trees and shrubs, uproot the stumps. After this, it is necessary to remove the top fertile soil layer, rich in organic matter.

Organic inclusions in the soil tend to decay over time, as a result of which the soil volume decreases, so that the plate, poured over the organic material, sooner or later finds itself in a suspended state, which does not have the best effect on its carrying capacity.

After removing the chernozem, you will need to plan the area - aligning it in the horizontal plane. For this, a level is usually used, by means of which the horizontal is determined. But, since not every landowner has this tool, and not everyone knows how to use it, you can apply the laser level.

The lowest point of the foundation of the future building is taken for "zero" and the whole area is leveled along it. You can also apply a combined method of excavating and backfilling, when the soil selected in the high part of the site is used to raise its low part.

When pouring the foundation foundation, it is necessary to use the backfill very carefully, since the bulk soil has low load-bearing capacities. Spilled part of the site should be carefully tampered to avoid a drawdown of the foundation in this place after construction.

Forming a protective cushion

Sand-gravel cushion will soften the effect of the soil on the slab

Sand-gravel cushion will soften the effect of the soil on the slab The next step is to create a multi-layered protective cushion, playing the role of a buffer between concrete pouring and soil. Above the ground, a layer of coarse sand, gravel or rubble 10-15 cm thick is deposited. It is necessary to soften the pressure on the concrete base from the side of the seasonal soil heaving forces.

Sand-gravel pillow after piling is rammed for greater density with a vibration plate or manual rammer in the form of chocks with handles attached to it. When erecting a foundation foundation on clay or marshy soils before gravel is poured, the ground is covered with geotextiles, which will prevent the deepening of the protective layer into the ground.

Over the gravel is poured a protective leveling screed from "lean" concrete - M-100 ... M-200 grades. Its name was given to this solution because of the low percentage of cement in relation to the fillers.

On the gravel layer, lay a layer of insulation

On the gravel layer, lay a layer of insulation Above the leveling screed is laid a heat-insulating layer, which prevents the freezing of rough floors in winter. It is made of high-density foam or extruded polystyrene foam.

Between the layer of insulation and a sand-gravel cushion a layer of waterproofing is made of rolled materials - roofing material or its modern analogues. With the help of waterproofing stop the penetration of dampness from the soil into the layer of insulation. The second layer of waterproofing is laid on top of the heat-insulating materials, after which the concrete plate is directly concreated.

Formwork and Reinforcement

Install a metal frame inside the formwork

Install a metal frame inside the formwork Formwork for a monolithic slab in comparison with the formwork for band-shaped foundations is simple in design. Along the entire perimeter of the future base, boards from boards are fixed, which are fixed in the vertical position by stops. Inside the formwork above the layer of waterproofing, a reinforced reinforcement frame is arranged. Structurally it represents two nets of reinforcement, located one above the other.

Grids are made of steel or fiberglass reinforcement. For these purposes, a reinforcement with a diameter of 10 - 16 mm is taken, while it is desirable that the lower mesh is made of thicker reinforcement than the upper one.

Between the mesh and waterproofing on one side and the surface of the plate - on the other, a protective layer of concrete should be located at least 3-5 cm. Therefore, under the lower mesh, metal or stone mortises are fixed, and the upper mesh is fixed so that the poured surface is higher than it .

Between the mesh and waterproofing on one side and the surface of the plate - on the other, a protective layer of concrete should be located at least 3-5 cm. Therefore, under the lower mesh, metal or stone mortises are fixed, and the upper mesh is fixed so that the poured surface is higher than it .

The size of the grid cells must be 2 x 2 or 3 x 3 cm. The metal fittings can be connected together by means of electric welding or by wire binding. Fiberglass reinforcement is fixed to each other with the help of special clips. The upper mesh is connected to the lower mesh with vertical racks, resulting in a spatial construction. For more details on the installation process, see this video:

The filled solution is sealed with a vibrator

The filled solution is sealed with a vibrator To fill the monolithic slab foundation is used concrete grade not lower than M-200. When building massive buildings - for example, residential houses made of brick or stone, the best option is concrete M-300 - M-400. The technology of pouring is not very difficult - concrete is poured to the required level and leveled.

When pouring, the solution must be compacted with a vibrator. Filled concrete contains in its composition a large number of air bubbles, which makes it less dense, porous, and this reduces the overall strength of the entire supporting structure.

During vibration, the concrete solution thickens, fills the entire space inside the formwork, air bubbles emerge from it, rising upwards.

During vibration, the concrete solution thickens, fills the entire space inside the formwork, air bubbles emerge from it, rising upwards.

Another nuance that must be observed when concreting the slab base is that everything be done without stopping in one day. If you allow the drying of one part of the pouring, in this place, during further work, a seam weld is inevitably formed. And he is the "weak link", capable of weakening the monolithic slab. On how to apply a deep vibrator, see in this video:

Also, when pouring the slab, you should carefully level its surface. In the future, this will greatly simplify the finishing work, will save time and effort when installing finishing floors.

As can be seen from the instructions, it is quite possible to make a foundation for the house at home to every person, even without a lot of experience in construction work. The most important thing here is to make the correct calculation and carefully observe the technology of the foundation-plate construction.

And its durability depends on how carefully the builders comply with the technology. The slightest deviation from it can lead to irreparable consequences, which can only be eliminated by a complete reorganization of the building.

How correctly to pour the foundation under the house so that it would serve the owners for many years without carrying out measures to strengthen it () or complete replacement?

Fill the concrete mixture in or trench after preparing the cushion and mounting the reinforcing cage.

If you want to know how to properly fill the foundation with your own hands, carefully study the procedure:

- The first step is to check the consistency of the concrete mix. If it has thickened, it is diluted with water and re-mixed until completely homogeneous.

- In the process of pouring the mixture must be rammed. If this is not done, air cavities are formed inside the monolith. Frozen concrete with such a defect will react to sudden temperature changes by cracks and fractures. Naturally, from such a foundation it is not necessary to wait for the necessary strength.

It is best to pour concrete into the formwork () in one step. For large construction companies, this is not a problem, because they are fully equipped with special equipment.

Another picture is observed in private construction: there are no mixers and concrete pumps for developers, and access roads for heavy equipment can not always be organized. In this case, there is only one way out - pouring the foundation in parts.

This method is allowed, but some rules are required:

- between pouring individual batches of mixture into the formwork, the time interval should not exceed 2 hours in warm weather or 4 in the off-season. In this case, the seams between the layers do not have time to form, therefore, the strength of the structure will not be affected;

- if there is a longer break in work, it will have to be extended by two - three days. During this time, the filled portion of concrete will harden, and the load from the next to the appearance of microcracks in the monolith will not.

After a long break, the surface of already filled concrete is cleaned of dust, moisture and dirt and cleaned with a metal brush. This is done to ensure a good grip of the seam.

Types of seam arrangement

Seams in a monolith can be located:

- vertically;

- at an angle;

- horizontally.

According to the requirements of SNiP, piles and columns can be layer-by-layer filled only with the formation of seams, located horizontally. allow the presence of vertically oriented seams. In this case, the armature, located horizontally, must connect the corners of the building.

Horizontal joints require installation vertical fittings without fail. In practice, monolithic tapes are flooded with horizontally oriented layers, since the creation of separate monolithic blocks is more labor-intensive.

Features of foundation foundation pouring

If you ask a professional builder how to properly fill the slab - the foundation under the house, get a definite answer: just in one go.

If you ask a professional builder how to properly fill the slab - the foundation under the house, get a definite answer: just in one go.

In building codes, the methods of step-by-step pouring are not even considered. Nevertheless, many private developers are forced to commit this "crime".

Although some experts say that it is better to put them better at a slope - this will reduce the probability of breaking the finished slab.

It is better, of course, to make horizontal seams, but because of the large area, the fill layers can turn out to be too thin. You can not allow this: if the volume of the portion is small, it is better to make vertical seams.

Foundation filling under walls from a beam and foam concrete

The best option for construction wooden house ribbon shallow foundation (). The depth of its laying is 500-700 mm.

The best option for construction wooden house ribbon shallow foundation (). The depth of its laying is 500-700 mm.

To reduce the depth of freezing, the soil around the foundation is insulated. How correctly to pour the foundation under the house from the timber? It is subject to the general rules referred to above.

On solid non-heaped soils, a low-buried foundation is suitable for a house made of foam blocks. If the soil is prone to tufting, the building in one floor is put on poles or piles.

With the rules for pouring ribbon foundations, we have already read, so let's figure out how to properly fill the house with foam blocks.

Pillar filling is possible at a time if possible. But it is allowed and layered pouring, observing the time frame, typical for the construction of banded foundations.

Vertical seams in this case are not unambiguously allowed.

The finished columnar supports are united in a single system using monolithic foundation beams. Keep in mind: grillage and beams are poured in one step.

Video about how to properly fill the foundation of the house.