Relatively recently in the domestic construction industry there was a new technology for erecting houses, which is a frame construction of houses. This direction from year to year is gaining popularity. The method of joining metallic elements has both advantages and disadvantages.

Metal frame buildings from profile pipes

In the construction of buildings with the use of a frame was used before. For example, this method involved in the construction of industrial buildings - shops, warehouses, greenhouses, hangars, farms, etc.

Over time, the technology has undergone modernization and now the frame from the profile pipe is used for the construction of public, residential and commercial buildings - shops, shopping centers, cafes, service stations and refuellings, low-rise buildings, cottages.

Advantages of metal frame technology

In many countries around the world, about 70% of residential buildings are built according to this method.

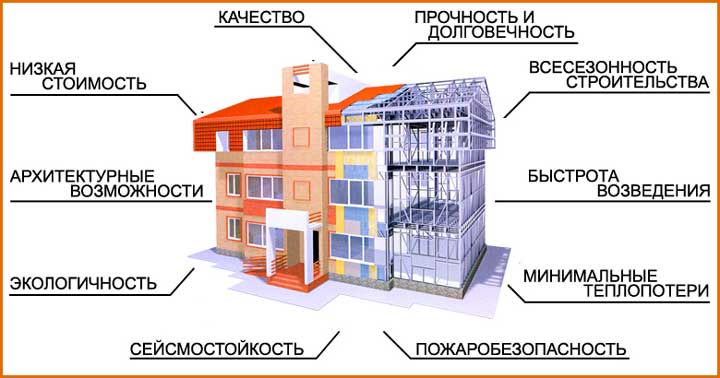

Advantages of metal-frame technology are many and this allows it to give preference to it when designing the construction of their own households:

- The greatest advantage of self-construction of a building from profile pipes is considered a small cost price in comparison with traditional technologies, which cost much more. The price of the frame structure directly depends on the materials from which it is planned to assemble, and the size of the pipe cross-section, which in turn depends on the scale of the construction. Let's say you need to make a frame from a profile pipe that has a section of 60x40 mm for a ladder. The material used will be cheaper than the products for the frame of the house. It requires products with a larger cross-section. In addition, for single-storey houses need pipes of smaller diameter than for two-story buildings.

- Another plus is the speed of erecting the object. If you build a house from a profile pipe, the time spent on construction will be reduced at times.

- The weather in no way affects the speed of work, because wireframe technology does not involve the use of so-called "wet" processes. The only exception is laying the foundation. Often a base is not required for a building, for example, when erecting a temporary space from the profile tubes of the frame.

- In houses built on the basis of frame technology, there is no shrinkage. In the process of erecting and operating the building does not change its shape and there are no cracks on it. Read also: "".

The main advantage is the lower labor costs in comparison with the already traditional technologies. To build a house for a house master, you need to attract a couple of assistants and take a month's leave. This is the time it will take to complete the main stages of construction. After that, the internal work can be left until the next vacation. As for the garage of profile pipes, it will take about a week to build it (in more detail: "").

Disadvantages of houses from metal frames

Before you begin the construction of an object according to wireframe technology, you must weigh all the positive and negative characteristics of such houses.

The advantages of the method are obvious, but there are also disadvantages:

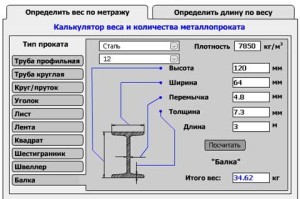

- First of all, it is necessary to note the complexity of designing. It is rather difficult to determine the load on profile pipes in wireframes, so if you have problems with the calculation, it is better to apply for services to professionals. They will assist in determining the permissible value of the load per one meter of tubular products. To select the pipes, determine the optimal cross section for them and the thickness, you can use a special program - an online calculator for the profile products.

- Another important negative point - the price. Metal material has a high cost, if compared with a wooden beam. Each developer in choosing a pipe product proceeds from his own financial capabilities, but experts advise in this case not to save and thereby ensure the strength of the building for many years. Especially, this applies to the use of frame technology for a residential house, and not for a garage.

- The big drawback of buildings from metal frames is that they are difficult to insulate. Problems with thermal insulation are due to the fact that these structures contribute to the penetration of cold air inside the house. In the premises of such buildings, the air cools quite quickly, even if it is intensively heated. It is necessary to warm this house very qualitatively, both from inside and outside. As a result, there are additional costs.

Construction of frame houses from proftrub

Before you start such work, you should familiarize yourself with the relevant information, study all the nuances of assembly of frame structures and the sequence of the processes. In many respects the successful result depends on the availability of the skills and abilities of the home master, since the erection of the frame can not be called a simple matter.

Features of the structural solution

The main elements of an apartment house are:

- foundation;

- the frame of the building;

- finishing - external and internal;

- heat insulation;

- the roof frame.

The foundation for a residential building built according to the frame technology, it is necessary to equip, since without it the building will not last long. Its construction is easier than the construction of a base with the traditional erection of housing.

Without a foundation, it is possible to build a skeleton made of proftrub for non-capital constructions, for example, greenhouses, which, if necessary, can be moved from one site to another (more detailed: "").

For the construction of the frame, pipes with a square section of 100x100 mm are most often chosen, and 60x60 mm products are used less often. The value of this parameter for pipe production depends on the size of the object under construction.

For interior finishing use pile boards from coniferous wood species with a width of 40-60 millimeters, pre-treated with antiseptics and antipyretics. For exterior facing use siding or facade plaster, but the best choice will be a natural tree.

On top of the log of pipes lay the rough floor of the boards. A profile covering is placed on top. Of the heat-insulating material, foam or extruded polystyrene foam with a thickness of 60-100 millimeters is used. The frames of the frame are insulated with foam strips.

The roof can be constructed by one of two methods: it will be part of a general construction or a separate frame element. Roof rafters made from proftrub are made depending on the coating material. Than it will be easier, and the corner of a skeleton is more, the it is necessary to choose pipes more thinly.

Step-by-Step Construction of an Object

Regardless of whether a dwelling house or a bath from a profile pipe is being constructed by oneself, work is begun with the arrangement of the foundation. Before proceeding with its laying, it is necessary to determine the bearing capacity of the soil and the level of occurrence of the subterranean water layers on the site of erection of home ownership.

For frame construction, a concrete frame frame is suitable. The main thing to remember is that the stronger and more reliable the foundation is, the longer the house will last. If the foundation is misplaced, its conversion will be expensive.

When the building is small, it can be erected on a non-capital base - this will allow you to move it if necessary. Unlike greenhouses and greenhouses, the foundation for a residential building must be built up necessarily. After his laying on, they begin assembling the frame of the house from the proftrub.

Assembling the factory frame structure is carried out without using a welding machine, everything is done with screw connections. With a homemade design for the house will have to tinker much more.

When assembling the metal frame from profile pipes, it is necessary to keep under strict control the quality of the connections obtained and the correct arrangement of the elements, and in this case, welding can not be avoided. It is the poorly executed docking of structural details that is the most vulnerable place.

Mount the frame starting with the installation of vertical elements, such as racks and columns, which in the process of assembly will be connected to horizontal elements of thin tubes. Then, in order to strengthen the construction, braces are used. Docking the frame parts is done from the bottom up. At the very end of the assembly of the roof part.

Frame construction is a relatively new direction in the Russian market. Rapid erection of the frame of a house from a profile pipe or wooden beams makes such a technology of construction of housing and architectural forms of a small size popular.

The profile pipe has its advantages and application features, and frame-type structures have many advantages.

Brief information about frame construction

At the first stages of development, metal frame construction was used only when building industrial buildings. On the skeletons of the profile pipe or channel, workshops, warehouses and hangars were built.

In the process of technology evolution, it became possible to use the frame from the proftrub for the construction of the following facilities:

- Residential premises of small number of storeys (construction is allowed not more than 3 floors).

- Cottages.

- Buildings for commercial use (shop, cafe, gas station, office room).

- Public buildings.

The main advantages of houses on a metal frame

The technology of erecting houses on the basis of metal frames is used all over the world. The most widespread technology is in the US, Japan and Western Europe. Residential buildings of these countries, built on wireframe technology, occupy an average of about 60%, and such construction continues to grow.

Frame houses have the following advantages:

- Low cost price. Compared with the buildings, which were built using traditional technology, frame houses do not require large expenditures. However, it is worth remembering that the frame of wooden beams will be cheaper than a similar construction from a profile pipe. Also the cost of metal elements for the frame depends on the cross-section of the pipe.

- Rapid erection. Residential houses with the use of wireframe technology are erected faster than with traditional construction. Using as a basic material for the frame profile pipe, you can several times reduce the construction of housing.

- Elimination of wet processes. The frame of the house from the profile pipe allows you to build houses all year round in any weather. The only exception is the arrangement of the foundation.

- No shrinkage. Frame houses do not require time to shrink, either during construction or during the operation of the building.

- Low labor costs. You can build a frame of the house from the profile pipe with your own hands. To build a house for wireframe technology, only a few assistants will be needed. It is possible to perform the basic construction of the house within one month. Remains only decoration inside the house. At the same time, traditional construction under such conditions is simply impossible.

Along with a set of positive characteristics, frame structures also have disadvantages. The main disadvantage of the technology, according to which the house is built from the prof pipe, can be called a complex design. To properly calculate the load on the profile pipe in a certain place in the house, you need the help of a professional. Only he can accurately calculate the weight that can be borne by the profile pipe.

It is also difficult to independently choose the cross-section and thickness of the material and calculate the size of the profile pipe. It is worth considering that the calculation of wooden beams is much easier.

It is impossible not to mention the problems with thermal insulation. Being a kind of bridge of cold, the metal frame requires better insulation. And this inevitably leads to additional costs.

Technology of erection of a metal frame house

The apparent simplicity of a house on a metal frame is just an illusion. In fact, the construction of such structures is quite complicated. Its main elements can be called:

- Foundation of the house. You can use lightweight foundation types, but you can not neglect this part. The base is not required for transportable buildings, which include greenhouses or greenhouses. In this case, the calculation of the profile pipe is carried out with appropriate adjustments.

- Metal carcass. For the erection of this part of the building is suitable profile pipe, which has a square section of 10 * 10 cm or 6 * 6 cm. You can determine the required dimensions of the pipe using the profile pipe calculator, taking the dimensions of the house under construction.

- Sheathing of walls inside the house. Optimal option for interior finishing is a sheet pile with a width of 4-6 cm from coniferous trees. The material must necessarily undergo treatment with antiseptic compounds and solutions that prevent inflammation.

- Rough floor and its finish. Lags are laid from a similar profile pipe, on top of them lay the rough floor of the boards and cover with any profile coating.

- Heater. The most popular material for the insulation of the frame house is extruded polystyrene with a thickness of 6-10 cm. For additional insulation of the frame from the profile pipe, strips of foam insulation can be used.

- Finishing the exterior of the house. For finishing work outside the building can be used facade plaster or siding. With a sufficient budget for construction, it is possible that the house can be finished with natural wood.

- Roof. The roof frame of their profile pipe can be erected as a separate structure or as one of the elements of the frame. Depending on the roofing material and the angle of installation of roofing rafters, calculation of the pipe parameters is performed. The lighter the roofing material and the greater the angle between the rafters, the more current the pipe can be used for.

Stages of frame house construction

The houses from the profile pipe with their own hands are erected in a certain sequence:

- Foundation. For the construction of frame houses, you can use a capital concrete frame base, as well as non-capital, for example, on screw piles. Houses on the second kind of base can be transported, since they are transportable.

- Mounting the frame. At this stage, the use of ready-made frames of factory production is allowed. To assemble these frames, no welding is required, all the elements are connected with screws. Do not exclude the independent construction of the frame from the profile pipe. It is important not only to monitor the mutual arrangement of elements, but also to control the quality of the connections. It is these places that are considered to be the weakest point in the construction of frame houses from a profile pipe. Installation work must be carried out from the bottom up. In this case, the first to install columns and columns, for the connection of which horizontal elements are used from tubes with a smaller cross-section. To strengthen the vertical elements use the braces.

- Roof installation. Roofing is mounted at the latest stage of the main construction. At the same time the team of builders can be divided into two parts: one deals with the roof, the other goes to the insulation and finishing.

- After the completion of the installation of the frame, you can proceed to the interior finish.

According to experts in the field of architecture, metal frame technology will take a leading position in the future. This means that the construction of a frame house from a profile pipe with your own hands allows you to get certain skills that can be useful not only for personal purposes, but also as an additional specialty.

Skeletal erection of residential buildings is a relatively new direction in the domestic construction market. The basis of any small architectural form in this way is collected quickly, so the technology is gaining popularity. If you understand with the method of connecting metal parts, you will build buildings without the help of builders. Let's figure out how to build a frame of a house from a profile pipe with your own hands, and also discuss the advantages and disadvantages of such a design.

Skeletal erection of houses - a new direction in the construction market

Metal frame houses

Metal frame construction has been used in construction before. This method of erection was used in the construction of industrial buildings: shops, farms, greenhouses, warehouses and hangars.

After the modernization of the technology, wireframes from the profile pipe are used for the erection of public and commercial buildings (cafes, shops, refueling), cottages and low-rise apartment buildings. Technologies are used in the reconstruction and repair of buildings - the construction of wings and mansards, the construction of floors.

Advantages of frame construction

The whole world uses metal-frame technology in construction. In the US, Western Europe and Japan, 70% of residential buildings are built thanks to this method. Advantages of the technology is enough to stop the choice on it when planning the construction of your own housing.

Minimal man-hours are the main advantage of metal frame construction

- The first advantage of erecting a frame house from a profile pipe with your own hands is a low cost price. Traditional technology is more expensive. The price of the design will depend directly on the materials that you are going to use. The cost of the frame depends on the cross-section of the pipes, and the cross-section is selected depending on the scale of the structure. For example, if you need to assemble a ladder frame from a profile pipe (cross section 60x40 mm), the material will be cheaper than for a carcass of a house where the cross section is much larger. Also single-storey houses are built from a smaller diameter pipes than a two-story house.

- The next plus is speed. The use of profile pipes as a frame will reduce the time of erection of the building several times.

- In the wireframe technology, there are no "wet" processes, so the weather conditions do not affect the construction. An exception is laying the foundation. But often the foundation is collected without a foundation. For example, if you are building a frame of a greenhouse or a timepiece from a profile pipe.

- In buildings constructed in accordance with the frame technology, there is no shrinkage. During construction and operation, the building does not change its shape and does not give cracks. This is another plus.

The main advantage is less labor compared to traditional technologies. To build a house, you will need only a couple of assistants and a month off. During this time, you will have time to complete the main stages of construction, and leave the internal work until the next vacation. The frame of the garage from the profile pipe with their own hands is erected in a week.

Minuses of houses with a metal frame

Starting the construction site, weigh the pros and cons of frame structures. Advantages of the technology is enough, but there are also drawbacks. The main disadvantage is a complex design. Calculate the load on the profile pipe in the frame nodes is not as simple as it seems at first glance. If you can not do this yourself, contact a professional. It will help calculate the permissible load per meter of pipe. When selecting the section and thickness of the pipe, use the online profile pipe calculator.

Another disadvantage is the cost. Compared with a wooden beam, the metal material is more expensive. When buying pipes, people are faced with the problem of choice: to take cheaper and save or choose a thicker pipe and provide strength for many years. Here everyone judges on the basis of the budget, but it is better not to save. Especially if it's a house, and not a frame for a garage from a profile pipe.

Such houses are difficult to insulate - this is also a minus. Problems with thermal insulation arise from the fact that the metal frame contributes to the introduction of cold inside the building. In such rooms, the air cools quickly, even despite intensive heating. Therefore, it is necessary to insulate the building qualitatively: inside and outside. That is, you will have to spend extra money.

The metal frame contributes to the introduction of cold inside the building

Construction of a house from a profile pipe

To engage in such construction, it is necessary to prepare, to study all the subtleties of construction and the sequence of operations. The fact is that the simplicity of erecting a skeleton is only an apparent opinion. In reality, the design is quite complicated. It all depends on your skills and abilities.

Construction Construction

The apartment house is not an easy building. Here are its main elements:

- foundation;

- the frame of the house;

- interior decoration;

- heater;

- external finishing;

- skeleton of a roof from a profile pipe.

The foundation for the frame house is mandatory, without it the building will not be durable. Its composition and construction is much easier than in traditional construction. Without a foundation, small structures (greenhouses, greenhouses) are built, which in the future are carried over the site from place to place.

For the frame, square pipes are often used 100x100, less often - 60x60. The cross-section will depend on the dimensions of your future home. For interior decoration, use a pile of coniferous wood (width 40-60 mm), treated with antipyretics and antiseptics. External finish is done by siding or facade plaster. When you have enough money, a natural tree is recommended.

Insulate the building from inside and outside

On top of the log from the pipe, the board is laid as a rough floor. The tree is capable of holding the cold transmitted from the outside through the metal. On top put any profile coating.

As a heater, extruded polystyrene foam or polystyrene (thickness - 60-100 mm) is used. Using strips of foam is additionally insulated rack racks.

The roof is manufactured in two ways: as a separate frame structure or as an element of the general framework. Roof rafters from profile pipes are manufactured depending on the planned coating. The lighter the material and the greater the angle of the frame, the thinner the tube.

Step-by-step instruction for building a house

The construction of any building should begin with the installation of the foundation. But before laying it down, carefully study the bearing capacity of the ground and the height of the underground water at the site of the future house. For frame construction, a concrete-frame basic foundation is suitable. Remember: the stronger and stronger the foundation, the longer the building will stand. Correction of errors in the incorrectly laid foundation will be very expensive.

If the house is small, it is placed on a non-capital foundation. This will make it possible to transport the house from place to place. Platforms or screw piles are also used in those cases where the depth of freezing of the ground does not allow building a house low. This technology is often used when installing a foundation under the framework for a greenhouse from a profile pipe when building a warm winter garden. Unlike greenhouses and greenhouses, the foundation of a residential house must be built.

When selecting the section and thickness of the pipe, use the online profile pipe calculator

The frame of the house from the profile pipe is mounted after laying the foundation. Assembly of the factory frame is performed without the use of a welding machine, everything is fixed with screw connections.

With a homemade base for home work more. To assemble a metal frame from a profile pipe, it is necessary to control the quality of the joints and the arrangement of the elements. Without a welding machine can not do. Do not forget that the most vulnerable place in the frame is poor quality welded joints.

Mounting of the frame begins with the installation of vertical elements (columns and posts), which in the course of assembly will be connected to horizontal parts of thin pipes. Further, the structure is strengthened by braces. The joining of the frame elements takes place according to the principle "from the bottom up".

If desired, it is possible to assemble a hangar from a profile pipe

Roofing is installed last. At this stage, begin interior decoration, insulation and external work. The remaining materials should not be thrown away. They will be needed for the construction of economic buildings. From the pieces of pipes collect greenhouses, mini-greenhouses or used as arcs to maintain the film over the plants. If the pieces are long, they will form the skeleton of the canopy from the profile pipe with your own hands. After the construction of the garage, the canopy is easily disassembled.

If you built a house, then in the future you can build any other building. Now your hands are capable of anything. Even the frame of the hangar from the profile pipe you will collect yourself, the main thing is the desire!

- Application of a profile pipe in construction

- Pros and cons of houses with a metal frame

- Construction of a house from a metal profile

- The main stages of the construction of the frame from the profile

More recently, metal frame construction was used to build industrial buildings: hangars, shops, warehouses. Today, even in housing construction, you can find the frame of a house from a profile pipe. Usually it is a low-rise building (no more than 3 floors). Even more often it is possible to meet public, commercial buildings, the frame of which is made of a metal profile. Technologies of metal frame construction are used in the construction of various superstructures, wings, attic spaces.

Fast and all-season assembly, accuracy, environmental friendliness, reliability and durability - these are the advantages of frame construction.

Such a method of construction is most common in Japan, the US, Western Europe. The share of residential buildings erected there with the help of this technology is 45-70%.

Application of a profile pipe in construction

For the construction of residential buildings, the metal profile was used after it proved itself best in other construction sectors. Rectangular and square pipes have been used successfully for a long time:

Profile pipes have long been used for structures of various designs.

- bridges, towers, cranes;

- support power lines, mobile towers, masts;

- overpasses and bridges;

- construction farms of various purposes;

- industrial galleries (at metallurgical plants, thermal power stations, power stations);

- sports complexes;

- exhibition, trade pavilions.

Profile pipes are manufactured by electric welding method on welding mills. This ensures accurate product geometry. High quality is confirmed by means of non-destructive testing devices. The profile can be made of ferrous metal, galvanized or stainless steel. The latter option is the most expensive and is usually used as a supplement (including decorative) to a frame made of cheaper material.

LTD DESIGN PRESTIGE

Pros and cons of houses with a metal frame

The construction of the metal frame house is much inferior to the buildings built in the traditional way. In reality, all the major stages of installation of a single-story country house can be completed in less than a month (not counting interior decoration). In addition, houses with a frame made of metal profiles:

Houses with a metal frame are characterized by low prime cost, do not require "wet" works, do not shrink during the construction process.

- differ low cost (the cost of construction is directly related to the size of the section of the profile pipe and the absence of the need to hire a professional team of builders);

- do not require the conduct of "wet" work (excluding the arrangement of the foundation), which allows the construction of a frame in the cold season;

- no shrinkage during the construction and subsequent operation.

The serious advantages of buildings with a metal frame do not mean that there are no Fast. The main disadvantage is the complexity of design, incl. load calculation. It is quite difficult to make such calculations on your own, so you will have to contact specialists. It is necessary to know exactly what mass will sustain 1 m of the pipe. Another disadvantage is the high price of the metal profile. When buying material, you will have to choose between financial costs (if you buy pipes thinner) and the ability to build a frame with a margin of safety (if you buy a thicker profile). And another problem that arises with the arrangement of houses with a metal frame is thermal insulation. Metal - a good "bridge of cold", therefore, it is necessary to approach the process of warming responsibly, i.e. make the right choice of insulation and spend on quality material.

LTD DESIGN PRESTIGE

Construction of a house from a metal profile

The foundation is constructed more easily than for houses built by the traditional method. If it is planned to build a greenhouse, a greenhouse or other structure intended for moving, the foundation is not needed.

Good results include the use of expanded polystyrene (it is better to purchase extruded PP) with a thickness of 80-100 mm. Sometimes they use mineral wool. In the latter case, work on laying the insulation should be carried out in the absence of rain on the street. Metal racks are insulated with foam strips.

Interior decoration is made by means of a grooved board (width 4-6 cm) made of coniferous species. The timber must be pre-treated with antiseptic (from decay) and fire retardant compounds (to reduce the flammability of the tree).

Exterior finish is made through facade plastering, siding. You can also use natural wood, but this option will cost more.

The roof of the profile pipe can be an element of the frame or be constructed as a separate structure. The calculation is made taking into account the angle of inclination, the type of roofing material. Also, specific climatic conditions are taken into account: the amount of falling snow, wind loads.

LTD DESIGN PRESTIGE

The main stages of the construction of the frame from the profile

The foundation can be any: ribbon based on reinforced concrete, screw, columnar. If the foundation is non-capital, the structure can be transported. The frame is constructed from a profile pipe pre-treated with a primer. This operation is not necessary if a more expensive version of profile pipes is used, with zinc-plating or stainless steel. You can connect pipes in one of two ways:

Begin the installation should be from the installation of vertical racks, which should have a larger cross-section than the horizontal profile. It is better to strengthen the struts with braces. The roof is mounted last. The use of shaped pipes in housing construction will bring the proper effect only if the calculations are carried out correctly. And if you can mount the frame yourself, then the pipe size calculations, their number per unit area, is best entrusted to the trained specialist.

Frame houses, are popular in recent times, and materials for their manufacture are diverse.

The main criteria underlying the selection of building materials are sufficient strength, durability, safety for human life, waterproofness, heat protection, and high fire resistance.

The standard variant is a frame wooden house. In houses of frame type with metal profiles, about 85% of residents of European countries and the USA live. In the regions of Russia, a steel frame was previously used in the construction of industrial facilities, warehouse hangars and workshops. To date, it is most often used in the construction of residential buildings.

Frame type of houses made of metal

The basis of this type of house is completely made of metal. From it the skeleton of all overlapping is executed, and also. The thickness of the profiles used, and their shape for each specific case of their own, because they experience a variety of external loads.

These buildings have certain characteristics:

- a lightweight metal frame for a home largely reduces the weight of the structure;

- accelerated construction time: due to the straightness of the steel profile, you do not need a level, a special square, a plumb and a drill;

- reliable insulation protects against thermal surges.

When building a house on the basis of a steel frame, they are used, and their choice depends on climatic conditions. Metal will not need some processing and coloring, it is not subject to shrinkage, does not burn and does not rot, has an extended service life.

When building a house on the basis of a steel frame, they are used, and their choice depends on climatic conditions. Metal will not need some processing and coloring, it is not subject to shrinkage, does not burn and does not rot, has an extended service life.

It can be completely disposed of, while not polluting the environment and keeping the forest from cutting down.

A frame house made of metal can be erected at any time of year and in different climatic regions.

The technology of light steel frame implies the construction of small objects. As a rule, frame houses are built in one or two floors.

For production purposes, these facilities are 6 meters high and spans up to 12 meters. Rafting farms with a length of 24 meters will require the installation of special profiles.

Construction of a modern frame house made of metal profiles

Modern technologies are based on the use of lightweight steel structures made of thin galvanized steel that do not give way to wooden houses. The section of metal profiles is made in the form of letters C, S and Z, and this provides reliable rigidity of the frame.

Modern technologies are based on the use of lightweight steel structures made of thin galvanized steel that do not give way to wooden houses. The section of metal profiles is made in the form of letters C, S and Z, and this provides reliable rigidity of the frame.

Through the perforation of profiles and the creation of certain air layers, as well as the use of metals with different thermal conductivities, the main problem of the increased thermal conductivity of the material has been solved, which affects the occurrence of cold bridges and the formation of a certain condensate. This technology is called light steel construction. It provides construction of houses of high quality and allows also terms for its construction.

Advantages and disadvantages of metal profiles

At present, there is a certain bias towards this variant of houses. It is believed that a residential frame house of metal profiles, colder houses of wooden beams.

Due to the creation of modern technologies, this myth is completely destroyed. Profile for the frame of the house is protected from heat dissipation by certain heaters. And the space between all frame struts is filled with heat-insulating materials, for example, ecowool or. All this will allow to warm the house as much as possible. It is considered that the wooden basis of the house is more ecological and attractive than the metal one. But in fact, wood having a natural origin requires additional treatment from decay and, various insects, by impregnation with the use of chemical components and, different varnishes, paints and other means. They significantly degrade the ecological purity of wood. And use this treatment will need to be done regularly, and this will additionally require financial costs.

Due to the creation of modern technologies, this myth is completely destroyed. Profile for the frame of the house is protected from heat dissipation by certain heaters. And the space between all frame struts is filled with heat-insulating materials, for example, ecowool or. All this will allow to warm the house as much as possible. It is considered that the wooden basis of the house is more ecological and attractive than the metal one. But in fact, wood having a natural origin requires additional treatment from decay and, various insects, by impregnation with the use of chemical components and, different varnishes, paints and other means. They significantly degrade the ecological purity of wood. And use this treatment will need to be done regularly, and this will additionally require financial costs.

It is also believed that wooden houses are cheaper than houses built of metal profiles, since wood is less metal at a cost. When making a frame of a house made of metal, a smaller amount of material is used than with the choice of the basis of wood. The mass of the wooden object is much larger and should be of high quality and more costly than that of a lightweight house with a metal skeleton.

Installation and installation of a house with the use of technology of metal structures is much easier and much faster. Steel construction can be dangerous in terms of and can attract lightning in a thunderstorm. But houses of this type are provided with the correct and high-quality grounding of all steel parts. In addition, there is a special, and outside certain materials, dielectrics, and this allows to completely insulate the metal elements and parts.

The reliability of a metal frame house

The steel profiles used to create house designs are very light, they provide a certain strength, allowing the use of housing for a long time.  The reliability of metal structures is ensured by special profiles equipped with stiffeners.

The reliability of metal structures is ensured by special profiles equipped with stiffeners.

When used, galvanized steel is used. The coating of zinc profiles protects them from external corrosion. The steel frame is very resistant to external mechanical influences: it does not shrink and crack during the course of time, it is not afraid of any pests, and is fireproof.

In combination with heat-insulating layers of reliable materials, this frame house will allow you to live in it all year round.

Stages of frame house construction. Foundation

The lightweight construction of the metal frame and the low weight of the house itself make it possible to create that does not require increased performance for strength.

The lightweight construction of the metal frame and the low weight of the house itself make it possible to create that does not require increased performance for strength.

For these houses, a shallow base is made. The production of the foundation, and the type of its construction in the most part depends on the nature. Before beginning the laying of the foundation, it is necessary to study all soil indicators at different times of the year.

As a rule, the space between all the wall panels is filled with foam concrete or aerated concrete. It is possible to use thermal insulation with polyurethane foam. To do this, use a certain method of sputtering.

The space that we filled in should form a special dense layer that reliably and qualitatively retains heat. It is necessary to fill with foam all the cavities inside the metal profiles, and all the problem areas. Heat-insulating material should go high quality and when hardening form a dense coating.

The surface of the internal insulated walls must be covered with vapor-insulating building material in the form of a film. From the outside of the house walls are protected against wind. Recently, for warming and finishing, heatblocks are increasingly being used, including thermal insulation material.

Finish

Stone Finishing

For the design of frame walls of the house use all the common building materials.

For their decor, you can only use painting, as well as plaster. The original solution will be the finish for natural stone.

Use also finishing with silicate or decorative bricks,.

Cost of a frame house from a metal profile

The cost of a house with a metal skeleton will be composed of the cost of the following important indicators:

- project;

- materials;

- construction and installation work.

When buying a certain house assembly, the price will decrease due to the exclusion of an individual plan development. But the standard distributed project has its own price. The cost of building materials and works does not exceed the price of houses made of wood.

For example, the cost of a two-storey house of 6x6 m from panels with a rough finish will cost about 700 thousand rubles. If you choose the assembly yourself, you can significantly save.