Monolithic foundations - this is a type of structure, which is made by pouring a concrete mixture into the formwork, previously reinforced with reinforcement. The result is a sturdy construction that can withstand both compression and tensile stresses. Due to this, a monolithic reinforced concrete foundation allows the construction of a two-story and even multi-storey building.

Monolithic foundation is poured directly on the construction site with their own hands, representing a holistic structure. It has no seams, if you take as an example - a prefabricated foundation of FBS. Due to this, considerable durability is achieved foundation plate.

Advantages and disadvantages of monolithic foundations

Monolithic foundation has its advantages and disadvantages, which will allow you to better navigate the construction market, and most importantly - choose which reinforced concrete foundation is best suited for your purposes.

- the monolithic foundation is characterized by increased strength and the ability to withstand various types of loads. These pluses allow you to build a house on the heaving ground;

- the technology of manufacturing such bases makes it possible to build much faster with their own hands than the bases from FBS;

- a monolithic slab can be made of very different configurations, which is especially important when building a building with a nonstandard base form;

- reinforced concrete foundation has good waterproofing characteristics, if the thickness of insulation is correctly calculated;

- for manufacturing there is no need to use expensive lifting equipment, due to which the construction comes out somewhat cheaper;

- reviews of builders say that the technology is simple, properly pour a monolithic plate with their own hands can even low-skilled workers;

- the reinforced concrete foundation acts as a pillow, which protects the basement and the cellar from external factors.

- weak thermal insulation properties. If we calculate the thermal conductivity of concrete, we can see that the reinforcement creates "cold bridges", these are the minuses for the ability of the structure to keep the set temperature;

- high manufacturing cost. The price of works only over the construction of the foundation can reach the third cost of the entire building. FBS in this regard will cost much cheaper.

Varieties of monolithic foundations

Device monolithic foundation can be produced in 3 ways, which one is best to choose - depends on the purpose of construction:

- tape;

- plate;

- columnar.

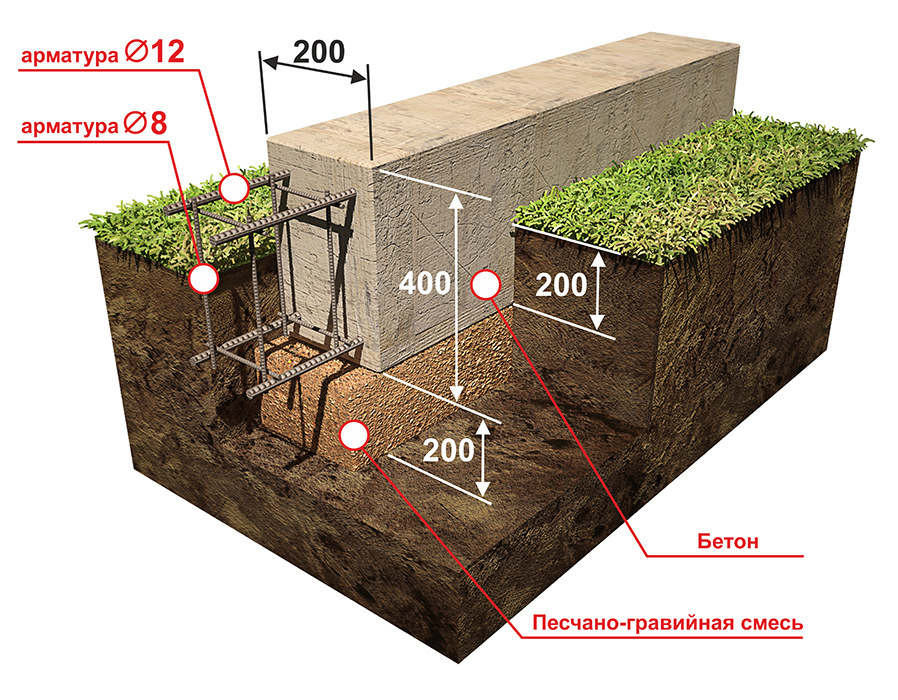

Tape monolithic foundation is placed along the perimeter of the house, and also as a foundation for the walls. This is the most popular type of foundation in order to build a cottage or a private house two-story type with their own hands.

It provides for the possibility of a semi-basement device that can play the role of a garage or a technical floor, as the modern cottage needs so much. The technology of such a foundation with proper operation requires the installation of a sand and gravel cushion.

The pillar foundation is not as reliable and durable as its counterparts, but its construction will cost you significantly cheaper. The columns are concentrated at the points of calculation of the greatest load on the base, as well as on walls whose thickness is less than the standard one.

The device of the plate foundation occurs under the whole area of the house. Thanks to its large footprint, it can withstand heavy loads and instability of the soil.

The main ability of the foundation slab is the ability to move with the soil, because the monolithic basement foundation also called "floating". But such a foundation can not be arranged on a slope and in places that are prone to flooding - because of the low height, such a base will simultaneously serve both the floor and the building.

Technology of plate foundation construction

Before starting the work, the first task is to calculate the future design. For this, it is necessary to take into account the type of soil, the depth of its freezing, the height of the location of groundwater and the climatic features of the region.

All this can be entrusted to professionals, but the cost of such work can scare away novice builders. Therefore, most often the calculation of the foundation slab is done by one's own hands, since a large margin of strength of the slab permits small errors.

In addition to the ground, the calculation also requires a pillow, that is, the sole of the foundation slab. If the soil is puchinisty with a high depth of freezing, then the pillow is made according to the maximum area base, evenly distributing the load on the ground.

When building on abrasive soil with low HPG, it should be borne in mind that the pillow will be located below the depth of freezing. If the soil has a small abrasion, the cushion is installed at any height.

Directly the technology of the device slab base own hands contains the following stages:

- Firstly, the calculation and marking of the plot under the foundation is carried out. The unevenness is checked by the level and the building level. The area of construction should be several meters larger than the area of the future house.

- Then, the pit is pulled out by oneself or with the help of construction vehicles. Ensure that the bottom is horizontal.

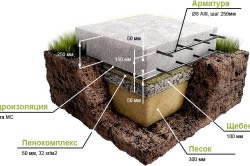

- A sand cushion is created to improve the stability of the plate. The sole requires obligatory tamping with the use of a vibratory plate

- The next stage is the installation of communications, as an example - sewage, drainage system and water pipes.

- Before the main layer is poured, the concrete preparation. It is to fill the layer concrete screed, a thickness of 10 centimeters, with the use of cement mortar M100. A bituminous primer is applied to the substrate.

- how foundation monolithic plate is covered with waterproofing, the seams of which can be joined by a blowtorch.

- Mounted formwork along the perimeter of the structure.

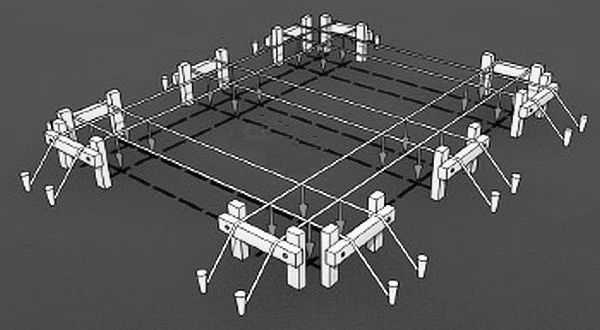

- The calculation and installation of the reinforcing cage, the diameter of the reinforcement from 12 to 16 millimeters is carried out. The grid cells should be about 20 × 20 centimeters.

- Filling the slab with concrete of the selected brand and sealing with a deep vibrator. After hardening of the concrete mix, the formwork can be removed. Full strength monolithic plate gets 28 days after pouring.

Warming of a solid foundation plate

Features of this type of foundation, such as a monolithic slab, require its additional insulation.

This solution will help reduce heat loss through the slab, and also reduce the subsidence of the soil beneath it. The problem of thermal insulation of the foundation is to think about the inhabitants of severe climatic regions, as well as those who have houses or a cottage on the ground where the thickness of the ground is above average freezing.

Thermal insulation of the base plate is possible both from the outside and from the inside. In case of external insulation, in order to keep the freezing point in the non-sooty soil, insulation of the ground is made under the pavement on the perimeter of the house. The technology of thermal insulation with expanded polystyrene requires the calculation of the given slope of the blind area, for example - about 2% of the base of the house. The thickness of the thermal insulation horizontally must be at least not less than the vertical dimensions of the insulation materials.

If external insulation of the foundation is not possible, the technology of thermal insulation inside is applied. In this case, the extruded polystyrene is laid from the side of the walls. Fastening of the material is carried out either on a cement basis, or mechanically fixed with subsequent finishing.

Technology of the monolithic foundation (video)

Comparison of monolithic and block foundations

FBS prefabricated type are manufactured at the enterprise and delivered to finished form on the building site. The human factor, when using production capacities, is minimized when the calculation of a whole monolithic foundation depends only on the person.

In addition, the prefabricated foundation FBS does not depend on weather conditions, since production is conducted in a closed shop. Plans to manufacture a monolithic base with their own hands can interrupt normal rain.

On the other hand, when choosing FBS, it is necessary to take into account the supply of concrete blocks, the distance of the enterprise to the construction site.

FBS is not flexible in the field of application in construction, and is used primarily for unified buildings.

Summing up, if you are planning to build a house with a unique look, non-standard forms, then it's worth paying attention to a monolithic reinforced concrete base. The typified prefabricated FBS is very narrow in application.

But prefabricated reinforced concrete is very good for small buildings, the costs for which do not pay off in a monolithic construction. FBS allows you to build an inexpensive small object in a short time, and a monolithic foundation is suitable for building a large shopping center, or as an example, with its help you can build a large cottage.

This page provides information on monolithic reinforced concrete foundations . We will consider tape, plate and columnar bases, examine their structure, advantages and disadvantages, design features and self-assembly technology.

Monolithic foundation foundation, is a single piece made of reinforced concrete. Such structures have a large bearing capacity and are equipped in the case of erecting buildings that have a significant mass.

There are several types of monolithic foundations:

Installation of a monolithic foundation

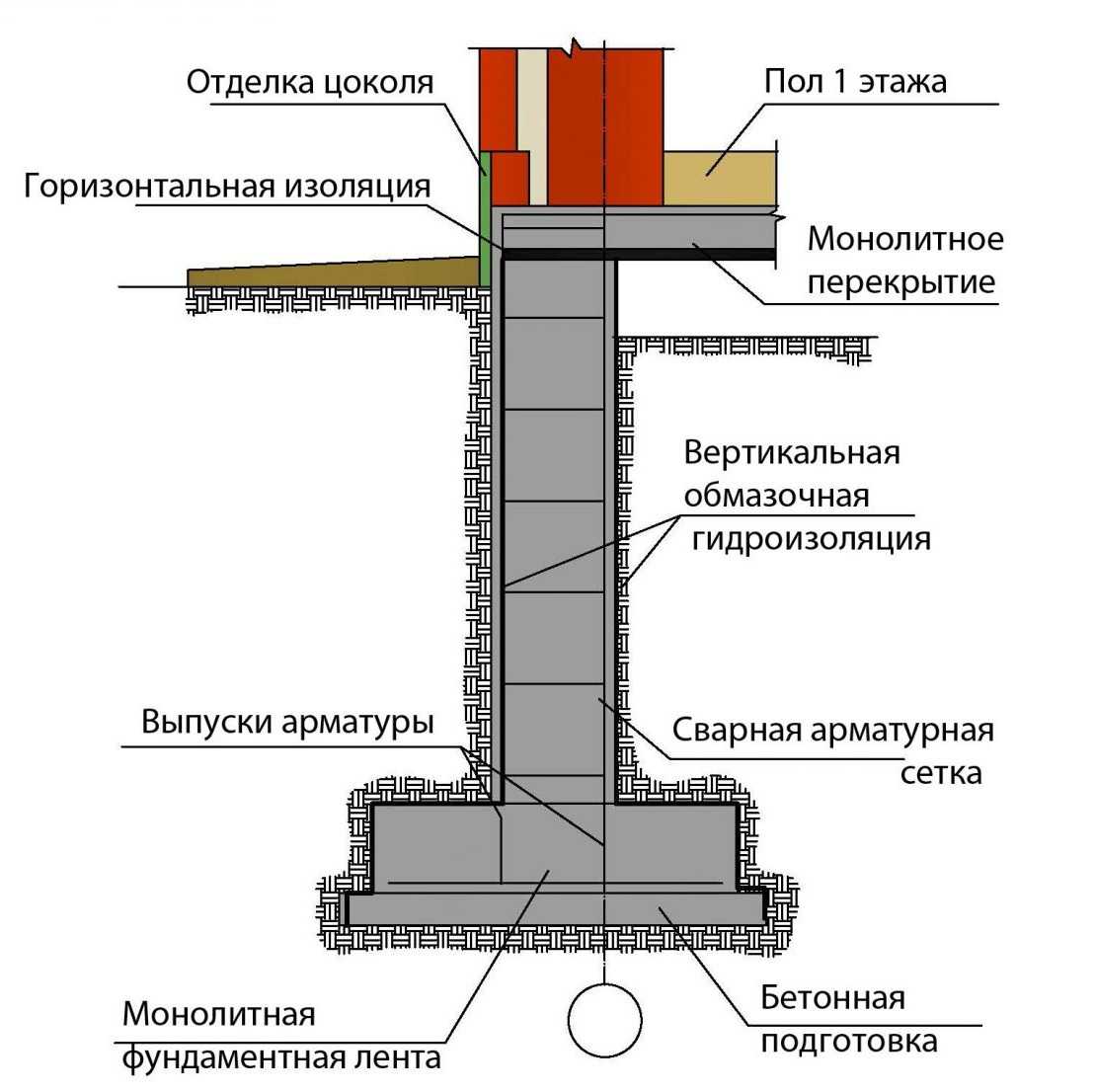

Any monolithic foundation consists of two elements - reinforcing cage and concrete body. After hardening, the reinforcement and concrete work as a single structure, perceiving and redistributing all the loads acting on the foundation.Reinforcement is a prerequisite for the arrangement of all monolithic foundations. The need for it is due to the low resistance of concrete to bending loads (such deformations the base undergoes under the influence of ejecting shearing forces), because of which there may be a cracking of the structure. The concrete itself effectively works on the compressive loads that it receives from the mass of the building.

Rice

Important: reinforcement of monolithic foundations is always performed in two longitudinal contours - along the upper and lower sides of the structure. There is no reason to lay a belt in the middle of the RC, since this part is not affected by strong loads.

The choice of the size of reinforcing bars depends on the dimensions of the foundation. According to the provisions of SNiP, corrugated rods of hot-rolled type A1-A3, diameter from 12 to 18 mm, should be used for reinforcement. To join the longitudinal carcass belts a smooth reinforcement of 8-12 mm diameter is used, which is bent into rectangular clamps.

Rice

The concrete body of the base is formed from concrete of mark M200 and M300. No less important factor is the type of aggregate mixture - it is recommended to use granite crushed stone with a size of 10-20 mm fraction. with flakiness up to 10%. The strength class is M800 and higher. As a filler, you can not use secondary and limestone crushed stone, because of their low mechanical strength, and smooth gravel - since it does not have sufficient adhesion to the concrete solution.

To the concreting of the monolithic foundation, the requirements for the rates of production are put forward - the foundation must be concreted so that the already filled layers do not have time to grasp until the moment of pouring a new portion of concrete. Otherwise, a network of microcracks is formed between the layers, which adversely affects the final strength of the structure. If possible, concreting the foundation must be carried out at the same time, with the use of ready-mixed concrete, ordered in the required volume.

Monolithic columnar foundation

The choice of the type of construction depends on the nature of the structure and features of the soil. Monolithic columnar foundations are used in the case of erection of panel or frame structures on sand and peat soils. Work on the arrangement of such a foundation is carried out in several stages:- drilling of the wells - it is required to lower the posts 25 cm below the freezing level of the soil;

- immersion of asbestos-cement pipes in the well - fixation is carried out with the help of soil;

- laying in the hole reinforcement, poured concrete;

- tamping the concrete mix with steel rod - the air is expelled from the mixture;

- a set of structural strength - occurs within 2 days.

Ribbon monolithic base

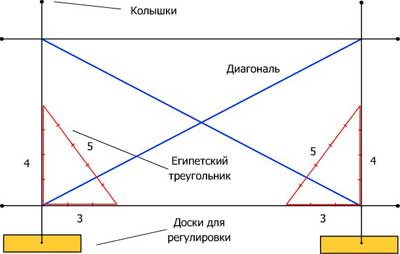

Monolithic strip foundation are manufactured using standard technology:- marking - along the perimeter and along the diagonal the cord is stretched, by means of which the rectangularity of the base is established;

- trench digging;

- casing installation - wooden boards are installed, supported by struts and fastened with bars;

- pouring the base with a concrete mixture - is carried out simultaneously with reinforcement, which is expressed in fixing rods on the formwork, covered with a layer of mortar being subjected to ramming.

Attention!! It is allowed to fill in layers, by filling a third of the height of the formwork and continuing the work, after the concrete mixture has been set with the required level of strength. Installation of reinforcing bars, located overlapping and bending, is carried out. The ramming process is performed using a vibrating platform.

Classical monolithic slab is in demand in conditions of sandy soils, characterized by constant shedding, ripeness and high location of groundwater. Such bases sustain dynamic movements of the soil, rising and falling with the building during thawing and freezing of the soil.

Recessed monolithic slab

Monolithic recessed slab is equipped according to standard technology:- cleaning of the territory and marking;

- preparation of excavation - extraction of soil at the required depth, with subsequent leveling of the walls and embankment on the bottom surface of the gravel-sand cushion formed layer by layer;

- formation of a drainage system - special ditches covered with geological textiles are made. Above sand and gravel pillow fit waterproofing layer in the form of a polyethylene film;

- creation of formwork - wooden boards with perpendicular angles are strictly installed vertically;

- arrangement of the reinforcing skeleton with the subsequent pouring of the construction with concrete mortar.

Calculation of a monolithic foundation

The purpose of calculating monolithic foundations is to collect the aggregate loads acting on the foundation, and determine the required base area, based on their size and soil characteristics at the construction site.Important: aggregate load on the foundation is the sum of the load from the mass of the house, snow pressure and useful operating loads multiplied by a safety factor of 1.2.

The algorithm for calculating the monolithic base is as follows:

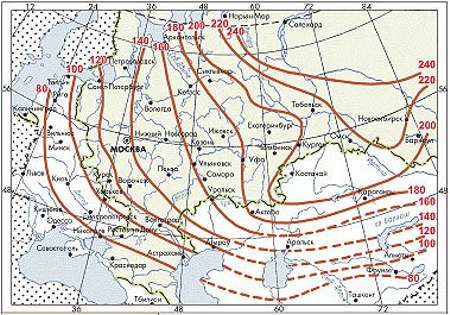

- The mass of the building is being calculated - the area of walls, ceilings and roofing should be multiplied by the specific weight of one square meter of building material from which they are made.

Rice

For example ( cottage with a wall height of 2.4 m, an area of 7 * 7 m with inner wall length 7 m): determine the total length of the walls (7 * 4) +7 = 35 m and their area 35 * 2.4 = 84 m2. We calculate the area of the basement overlap: 7 * 7 = 49 m, the attic floor area will be similar. Determine the area of the roof (taking into account that it stands for the contours of the walls at 50 cm on each side) - 8 * 8 = 64 m2. It remains only to multiply the received dimensions by tabular data.

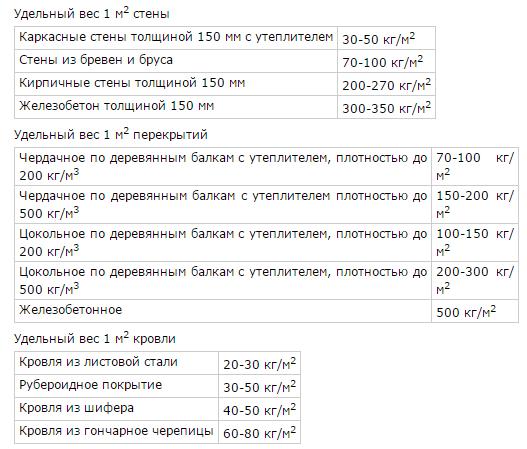

- The amount of snow loads is calculated - the area of the roof is multiplied by the average weight of the snow cover in a particular region;

Rice

- Determine the operational load. The average value of which for residential buildings is 100 kg / m2 of overlap (taking into account the basement and inter-floor overlap);

- Summarize the collected loads and multiply them by a reliability factor of 1.2;

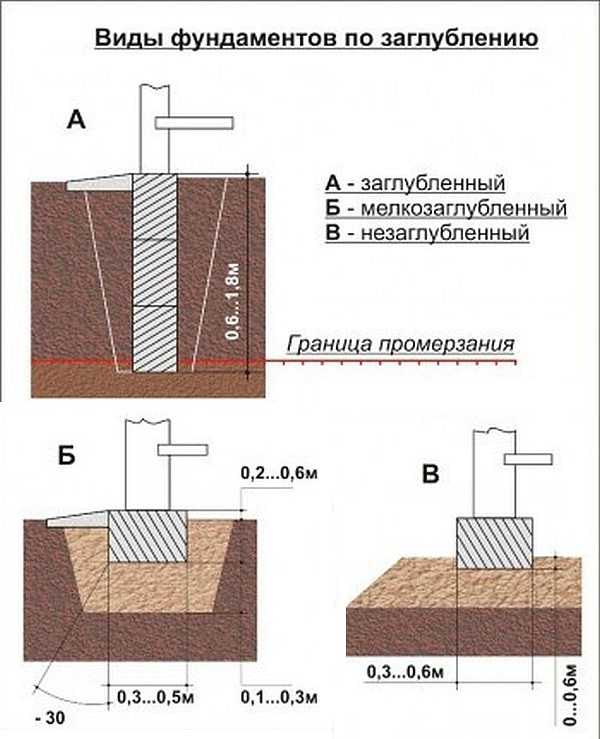

- Define basement depth ;

Important: in soils prone to frost heaving, the foundation foot of the foundation should be laid 20-30 cm below the freezing level of the soil. In shallow soil, finely buried foundations can be used with a depth of up to 80 cm). To the obtained depth, 30-40 cm is added to the basement part of the basement, which gives the total height of the base.

Rice

- Determine the reference area of the foundation.

It remains to calculate the total load on the ground (the weight of the foundation + the value of previously defined loads from the mass of the building and the snow cover) and divide them into the base area of the basement. As a result, we get the building pressure per cm2 of soil, which should be compared with carrying capacity of soil on the object.

The most accurate information on the characteristics of the soil can be obtained by running on the site geodetic survey . If this is impossible, use the table of the average carrying capacity of the soil.

Rice

Important: if the calculations showed that the load on the soil is within the norm, this foundation is suitable for construction. In case of exceeding the load, it is necessary to increase the base area of the base (its width) and recalculate.

Monolithic foundation by one's own hands, technology

The algorithm for constructing the foundations of band, plate and columnar types is given in the previous sections of the article. We will consider the critical errors in the main stages of installation monolithic bases, which is unacceptable.- Layout of the foundation before work;

Rice

It is extremely important to check the correctness of the right angles of marking, both on the inner and outer zones of the basement. This is done according to the rule of the Egyptian triangle - in the corner part of the base, from the point of intersection of the cord, 3 and 4 m are retreated and appropriate notations are made (pieces of electrical tape are attached to the twine). The distance between the marks is measured, if the right angle is correct, the length of the diagonal should be 5 m.

- Installation of formwork and a sealing pillow.

When assembling the formwork it is necessary to strengthen the lateral braces and transverse bridges connecting the side shields along the upper contour to prevent deformation of the mold under the weight of concrete.

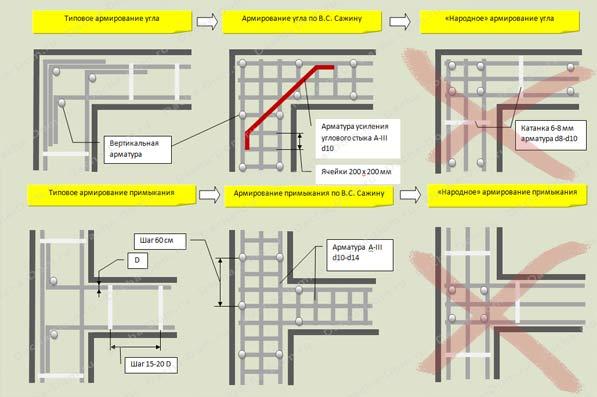

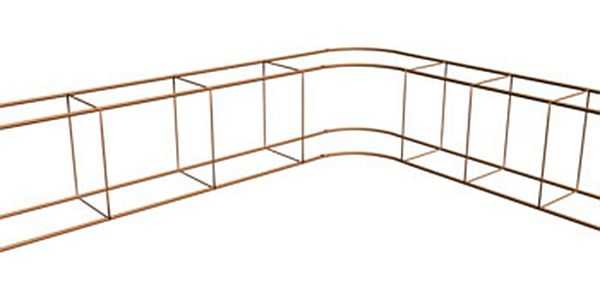

A typical error in the reinforcement of monolithic foundations is the incorrect joining of the corners of the frame, to which basic loads fall during the operation of the foundation.

Important: widespread cross reinforcement is unacceptable, it is necessary to connect the corners by means of curved L-shaped rods or according to VS Sazhin's recommendations - by reinforcing additional rods.

Rice

- Pouring and holding concrete.

Important: if the foundation is gaining strength in the summer, at temperatures above 20 degrees, the concrete must be moistened daily from a hose with a spray nozzle, as when drying on the concrete, microcracks can form.

Advantages of monolithic foundations

Monolithic foundation plates, have a number of advantages:

- high level of strength in the horizontal and vertical plane; on the ground is distributed evenly;

- guarantee of unharmedness buildings in the case of mobile soils;

- bedding level groundwater irrelevant;

- increased load bearing capacity;

- tightness and durability - the structure of the structure preserves its integrity.

Cost and calculation of a solid foundation for the house

The only drawback is the high cost of the base, which consists of the following factors:

- dimensions - length, width;

- depth of excavation;

- preparation: sand, concrete, crushed stone;

- reinforcement , concreting.

Type of monolithic concrete foundation

Ironically, now monolithic foundations are very popular, and this despite the fact that erecting them is quite expensive from a financial point of view. In addition, the technology for erecting such a foundation must be clearly defined by calculating the maximum load on the area, as well as the points of the key angular loads, taking into account the impact of external factors.

Such a foundation is not so difficult to make, but it is sometimes necessary to consult with professional builders who already have experience and practice in creating a monolithic foundation for multi-storey buildings of various applications, as well as their further restoration repairs. The technology of creating a monolithic tile foundation for the house is universal, besides, repair of such a foundation can be done in a short time. Only the device can differ depending on the type of soil, the shrinkage level, the availability of groundwater and even the degree of freezing in a particular period of the year.

But why is the monolithic foundation so popular among private traders that they are ready to pay big money just for the sake of its arrangement? First of all, this is a universal base, which is perfect for any type of soil, except permafrost, and the construction device is accessible to everyone. It is also ideal for clay and peat soils, where there is a large degree of subsidence, and the emergence of spontaneous groundwater. After all, any grounds do not like groundwater, especially strongly acidic due to the oxidation of peat, besides, it can easily be repaired.

All newcomers who have decided to build a monolithic foundation with their own hands, should remember that this design can be a carrier only if properly reinforced and shrunk. But it also takes into account the degree of shrinkage of the soil, its features, as well as the use of monolithic concrete (expensive option) or prefabricated concrete or reinforced concrete structures (a cheaper base variant).

Technology of erection of a monolithic foundation

- Layout of the future construction site, installation of guides and extension of the adjustable rope.

- Calculation of the bearing structure of the foundation, taking into account the nature of the soil, the selection of the optimal technology (for multi-storey buildings, only a buried, monolithic foundation should be used, other options simply can not sustain the weight of the whole house).

- Creating a pit. Here you can use manual or mechanized labor, it all depends on the financial capabilities of the customer and the time for erecting the foundation.

- Creating a pillow of sand and rubble. It is worth remembering that the pillow should consist of several layers, and the gravel layer is drainage.

- Construction of formwork. It should always be greater than the width of the basement, here it is necessary to take into account the degree of fluidity of concrete, as well as the hydrophobicity of the pillow itself.

- Waterproofing and thermal insulation. In some cases, it is not used, unless the basements and parking lots are structurally provided. But, if there are basements in the house, then you can not do without high-quality waterproofing. You also need to make thermal insulation to keep the heat inside the house.

- Reinforcement of the base. Here you need to do everything correctly, because due to reinforcement the degree of shrinkage of the building is sharply reduced, as well as the periodicity of the capital repair of the very foundation of the house. It is worth remembering that the reinforcement is carried out by various methods, depending on the type of building, its height and structure. Particularly, it is necessary to make reinforcement when there are several main and intermediate bearing walls. Then many builders make an expensive reinforced mesh, where once the main and intermediate reinforced lines are crossed.

- Fill with concrete. It is better to do it simultaneously with several concrete mixers, so that the concrete base is evenly distributed along the formwork.

Back to contents

Principles of the construction of foundation slabs of buildings and structures

Most often in the construction of houses used foundation slabs. The base of these materials is a structure with high reliability. Foundation plates can be prefabricated and monolithic.

A monolithic base can be used not only for the purpose of building a private sector, but also for large facilities that require the erection of a monolithic foundation. is associated with the manufacture of the base of the structure, performed with the use of solid reinforced concrete.

The technology of building a monolithic foundation of reinforced concrete is not only simple, but also allowing to guarantee the reliability and durability of the entire structure of the base of a building or structure. Cope with the construction of the foundation slab can be independently without assistance.

Building a foundation on the basis of monolithic slabs Overlapping has recently become widespread. The diagram (PICTURE 1) shows the types of grounds of a building or structure that can be used during construction.

There are two types of monolithic foundation:

- Plain.

- Reinforced (reinforced concrete).

At the device of the simple basis use concrete of mark 50 and above. Sometimes stones are used in the construction of its construction for the house. In this case, concrete is obtained, in which the mass of stones is 30 to 40% of the mass of concrete as a whole. The concrete itself is called butobetone, which, in its strength, is not inferior to ordinary concrete. The use of stone in the process of building monolithic bases can reduce cement costs, due to which the cost of construction is reduced.

Starting to pour concrete, prepare boards for which is of two kinds:

- Removable.

- Fixed.

Instead of formwork, sometimes use inventory boards or simply the walls of the pit, for which waterproofing is specially carried out with the help of ruberoid or polyvinyl chloride films. Otherwise, the cement "milk" will be absorbed into the ground, which will cause a reduction in the strength of the entire structure.

Monolithic band foundation It is an all-in-one construction made of steel reinforcement and concrete tape. It is located along the perimeter of the building and under all supporting walls and elements. With the observance of technology, the design becomes a single whole - a monolith - and has very high reliability and strength characteristics. For this reason, it is popular, as in the construction of multi-storey houses, and private cottages.

Monolithic tape foundation is advisable to apply at a low level of groundwater: when they are located below the required depth of the foundation. Otherwise, it is necessary to organize drainage, and this is additional (and considerable) funds.

Device and types

In the depth of bedding, the basements of the foundation are shallow and deep lying. Fine-cut ones can be used on calm, non-bumpy soils with good bearing capacity for building a small mass - from wood and erected on wireframe technology.

In this case, the tape should go 10-15 cm to the solid layer, which is located beneath the fertile layer. At the same time, according to the standards, it can not be less than 60 cm.

Monolithic tape foundations of deep laying are made for heavy, massive houses. In the general case, they are lowered 10-15 cm below the freezing level of soils for this region. In this case, the sole should be supported by a layer with a good load-bearing capacity. If it is not so, it is necessary to go deeper below. For example, if the soil freezing level is 1.2 m, and the fertile layer ends at 1.4 m, it is necessary to fall below 1.4 m.

With or without formwork

In general, the technology of erection of a monolithic tape foundation provides for installation. This is a structure of shields, which gives shape to concrete and does not allow it to spread. It is clear that the formwork - this is an additional cost for materials, as well as additional time for its assembly and installation.

Decking - a structure of boards or plywood, which gives the foundation shape

Sometimes, for the sake of economy, on good soils, the excavation under the foundation is digged exactly according to the marking - to the desired width and depth. And concrete is poured into these holes without formwork. Such a technology can not guarantee the required degree of reliability, it is impossible to predict the result. The fact is that for a set of normal strength concrete needs a certain amount of water. Without formwork, water, although a little, but absorbed into the ground, which can affect the quality of the concrete stone. In the worst case, it can crumble.

From the situation go out, spreading a plastic wrap in the trench. But on it then they go - reinforcement needs to be done. Both the bars and the boots damage the film more than once. As a result, the moisture still goes away.

A foundation without formwork is a risky undertaking

In some cases, such foundations can be defended for some number of years without problems. But sooner or later, cracks appear or concrete begins to crumble. The second difficulty of working with such a foundation is its far from perfect geometry. In order to reduce heat loss, the foundation is insulated, often with foam plates or extruded polystyrene foam. Try to paste them on an uneven surface. The same situation with vapor barrier: it is very difficult (almost impossible) to glue the film onto uneven, porous concrete with inclusions of soil. Whether this approach is justified or not is up to you, but you can recommend such a foundation only for a fence or a shed.

Basement in a house with a ribbon foundation

The basement can be the same area as the house, and can occupy only a part of the space. And determine its size needed before the design.

If the basement occupies only a certain part of the space, it will be possible not to remove the whole soil, but to dig only the trenches below the tape. Dig a basement, too, according to certain rules. Its placement and arrangement can also be developed at the design stage.

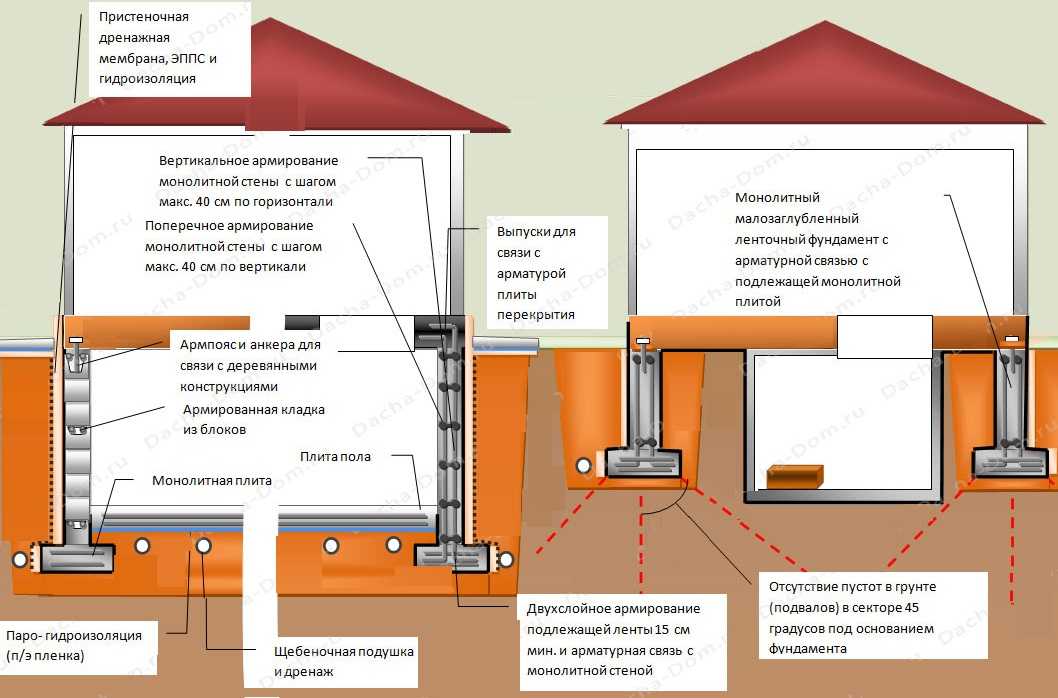

Tape monolithic foundation with a basement - a difficult task for design (to increase the size of the picture, click on it with the right mouse button)

If it was decided to make a basement later, then you need to choose a location and determine the depth so that when carrying lines from the base of the house at an angle of 45 ° they do not pass through the voids (shown in the photo to the right).

If the basement is under the entire area of the house, then the soil is taken out all the way to the required depth. In general, such a project is not budgetary: work and expenses are much greater. First, it requires reinforced reinforcement of walls and their greater thickness. Since there will be no soil inside, the walls of the cellar will have to resist the pressure of the soils from the outside. Therefore, the thickness of the tape will be much larger and the reinforcement is needed more powerful, it fits with a smaller step, and the number of reinforcement belts will increase. As a result, only on the foundation the consumption of reinforcement will increase. Secondly, it will require concreting and, possibly, reinforcement of the basement floor throughout the area. And this again materials - concrete and reinforcement. Third, effective ventilation will be required to remove underground gases. It is not possible to design such a structure independently. Work must be professional, and with great experience.

One of the options for building a basement for a house with a basement (to enlarge the size of the picture, click on it with the right mouse button)

Monolithic tape foundation: construction stages

Even if the building is an organization or a team, the developer needs to know the technology: this is the only way to control the process and be sure of the quality of the work.

In general, the technology is:

- Layout of the plot.

- Land works.

- Sealing base, basic backfilling and tamping.

- Ribbon marking.

- Waterproofing.

- Assembly and installation of formwork.

- The binding of reinforcement.

- Pouring concrete and vibrating it.

- Curing.

Some clarification is required. Double marking - plot and tape - is needed if the house is with a basement under the entire area of the house. The first time you mark the area of the house, taking into account the allowances for the installation of the formwork. There is no way to do without it. Then, after the pit is dug and the bottom is poured and tamped, it will be necessary to mark out the tape. On these marks, the formwork will be installed later, which will form the "profile" of your house.

Now a little more about each of the stages.

Layout of the plot

Since for the design of the soil was investigated in a certain area, it is necessary to be tied firmly. The underground structure is often inhomogeneous and a displacement of half a meter may be critical: suddenly there subsidence rocks or a cavity. With an accuracy of a centimeter, it is hardly worth positioning, but it is advisable not to miss too much.

Land works

Their volumes and the technique used depend on whether you have a house with or without a basement. If not, then you marked the tape - and you will need to remove the soil. Only with a margin for setting the formwork - and this is sometimes 50 * 80 cm on each side. For shields, spacers are needed that will not let them fall apart.

If the house with a basement - take out you will need all the soil. Dimensions of the excavation - 2-5 m more than the size of the foundation. It's still the same stock under the struts for the formwork.

If the house with a basement - a pit turns out big

For larger volumes it is better to use special equipment. Rent it is a lot, but the work of the brigade "diggers" within a few days will not be cheaper. The velocities are disproportionate.

The top fertile layer is stacked separately, it can be immediately distributed in the garden. The rest of the soil is piled up in a heap: in part it will go to the backfill, in part it will have to be taken out.

Sealing of the bottom of the excavation and padding

After the main mass of the soil is removed, the bottom must be leveled and compacted. When the excavator is working, it often happens that some sections have a depth of 20-30 cm more than necessary. All these unevennesses must be corrected: to fall asleep and tamper.

Tramping and leveling are needed throughout the entire area of the excavation or trench. And, not with the help of a deck. It can be used if you build a fence. Even when building a bath or a dacha, it is better to use a vibratory plate.

Let's see why. At this level, the entire load of the building. Even small voids and irregularities can cause uneven shrinkage and cracking. And the bottom after excavation of the land is uneven. And you can eliminate it with a ram. Even better, if a layer of sand with medium or fine grain is poured on the bottom. It is because of the smaller sizes it is better aligned. But for better and faster ramming it needs to be moistened (pour water to soak all its volume). The vibratory plate creates an effort, compacting sand by 15-20 cm. It is this layer that must be poured at a time. If the project, a layer of sand 30 cm, then pour first need 15 cm, shed and tamper it to a high density. Then pour the second one and shed it and ram it.

Often the project requires the creation of sand and gravel padding. Then a layer of crushed stone of the fraction 30-60 mm is poured over the compacted sand. And it is also tamped. The thickness of this layer of padding is 10-15 cm. It should also be poured in small layers of about 5 cm and each rammed.

In this case, the ground not only equals, it becomes even denser: the rubble is driven into the rock below, increasing its bearing capacity. Since the slab hits the stone with great force, the compaction occurs to a depth of 40-50 cm. And this is very good.

Formwork for a monolithic belt foundation

Formwork is made of boards with a thickness of at least 40 mm, low-grade plywood or OSB. Plywood is inexpensive, special - formwork. It has lamination on the one hand - there is a protective film. Because it can be used several times.

Shields from sheet materials are strengthened by transverse and longitudinal bars. Of the boards are fastened with cross bars. Expose the assembled shields on the marking of the tape, fix it from the outside with the cuts, and the spacers are installed inside. All these fasteners must give the formwork dimensions. They will not let the shields fall apart or stick out when pouring concrete: the mass will press on the walls a lot, so the fasteners must be reliable.

- an inapplicable attribute of a quality foundation

Reinforcement

Because of the features of the structure - a large length and a small width - the ribbon foundation is affected mainly by forces that try to break the tape across. Therefore, it is necessary to strengthen it on the long side. Here use a powerful ribbed reinforcement from 10 mm in diameter and more. All the transverse reinforcement only stabilizes the longitudinal bars in space, because it can be taken smooth and use a small thickness - 6-8 mm.

And in most cases, regardless of the depth of occurrence, two reinforcing belts are sufficient: at the top and at the bottom of the tape. The exclusion of a basement device with a basement under the entire house.

The diagram is shown in the photo. At each connection point, the reinforcement is connected with a special wire. Do this manually using hooks or automatic devices - knitting handguns.

There is another way: welding. But its use is not always justified. The work is faster, but the connection is hard. When the wire is stitched, the armature has some freedom. And this helps to compensate for some deformations without destroying the concrete. When welding joints are rigid, which is good on one side, but on the other, too rigid a structure can cause cracks.

One more thing: the place of welding always begins to break down first. Although the armature is in the thickness of concrete, and therefore is not exposed to corrosion (oxygen does not penetrate it), but with any disturbances and oxygen supply, welded joints are first broken.

At this stage, the ventilation ducts and boxes are laid, through which the engineering communications will be delivered to the house. If you forget about this, you will have to destroy the monolith and this is very undesirable: the less flaws, the stronger the design will be.

Filling the belt foundation

When building a more or less large house it is easier and more efficient to order the delivery of finished concrete to the site in a mixer. Then you can fill in one day.

You can do the concrete yourself. But this requires a concrete mixer. Manually, mixing components in the troughs to ensure the proper degree of uniformity is impossible.

For pouring manually, at least three people will be needed: one kneads concrete in a concrete mixer, the second distributes the finished portion, and the third vibrates the newly filled section.

Vibrating of concrete is carried out with the help of hand or portable submersible vibrators. This process allows you to delete all the voids, more evenly distribute the placeholder. As a result, the strength characteristics of concrete are much improved, it acquires frost resistance due to the fact that it absorbs water much less. Therefore, do not skip this step: with the same components in the solution, we get a higher grade concrete.

Another point: when pouring from the machine you need to use special gutters. First, they are easier to deliver concrete to the desired point, and secondly, the solution should not fall from a high altitude. If the height of the fall exceeds 150 cm, it is stratified. The result is low strength.

Curing

If the work was carried out in hot dry weather, the tape should be covered with a polyethylene film or any other material that prevents rapid evaporation of moisture. Since the depth of concrete is large, wetting the surface of tangible results will not. The main thing is not to let the top dry and the film copes with this task perfectly.

If the temperature during and after pouring is kept in the region of + 20 ° C, after three days after pouring the concrete will pick up a fortress of about 50%. And on the fourth day formwork can be removed and proceed to further work.

At lower temperatures, it is necessary to wait longer: at + 10 ° C it is already 10-14 days, and at + 5 ° C the setting process practically ceases. In such conditions it is necessary either to insulate the formwork, or to heat the concrete.

Monolithic tape foundation is ready, but there are still work on its insulation and waterproofing. Only after this, they fall asleep (backfilling).