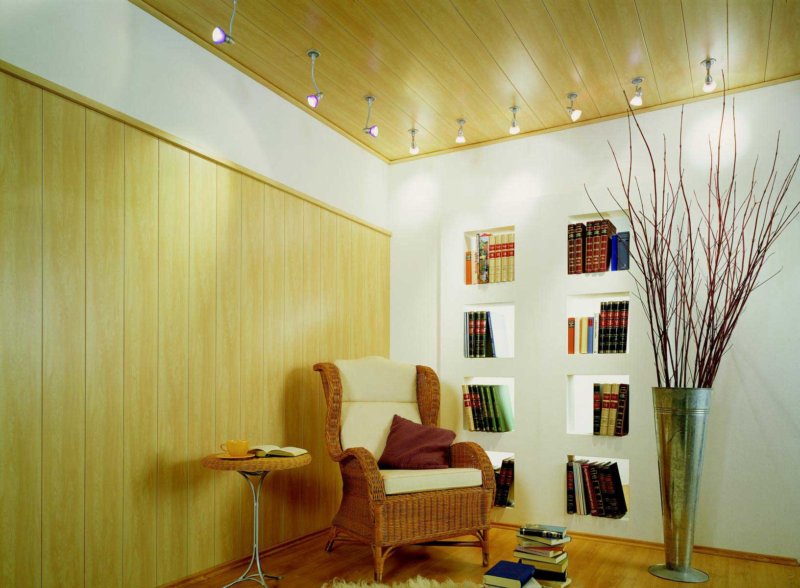

Correctly selected panels for walls will be the best decoration of the interior. They are easy to install, not demanding in operation, and also their cost is small.

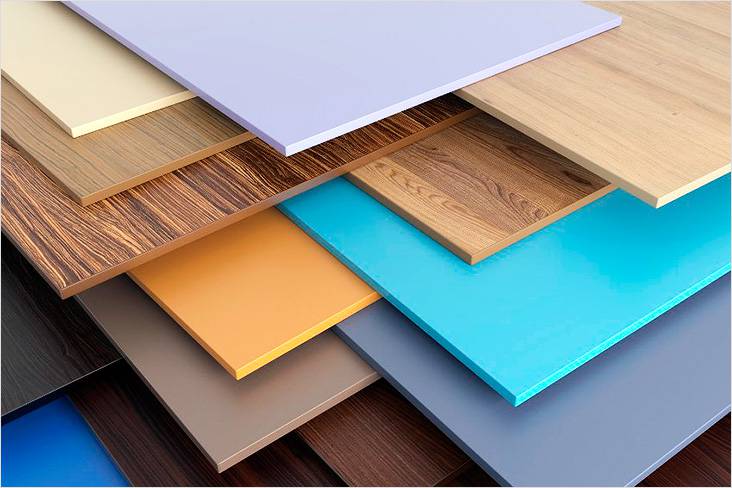

Differ from each other appearance and quality, and all thanks to the material that is used for manufacturing. There are several types of plates: plastic, wooden, fiberboard and PVC.

With this type of system, it is possible to decorate walls in a simple and inexpensive way.

Characteristics and basic concepts of wall panels

The decoration of the walls with panels is considered to be the most popular way of interior decoration.

In most cases, the installation is carried out independently, the main thing in this case is to take into account the type of elements and their production material. In our article you will find a step-by-step lesson of mounting the system on the photo of wall paneling.

Products made of natural wood are of the highest quality and reliable. Sometimes they are covered with wax, which makes it possible to use the system in rooms with high humidity.

Finishing the walls with wooden panels - the most environmentally friendly and safe way of decorating it without any doubts can be used in houses where people live.

Panels from MDF are the most resistant to any influences. They are made by the method of dry pressing from wood waste of valuable species of trees, and due to this the plates withstand any mechanical loads.

Wall decoration mdf panels is produced in those rooms where all other systems are inefficient and short-lived.

Wall decoration plastic panels will serve you a few dozen years, which will save a lot.

More recently, in the construction markets, glass panels and 3D systems have appeared on sale. With the help of glass slabs, it is possible to apply patterns to the surface of walls. They, as well as the above listed products are safe and withstand any kind of load.

With the help of a glass system, it is possible to decorate walls with decorative panels even in children's rooms.

Indeed, thanks only to these products on the surface perform different drawings, which are sure to please children. This is not the most popular way of decorating, because glass panels are too expensive.

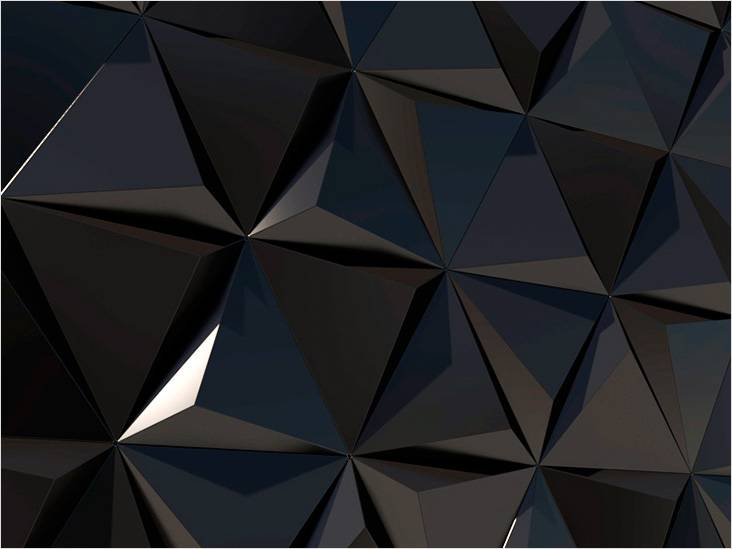

But 3D panels do not have the usual texture for us. Using such a system, for example, in the corridors, you can make the decoration of the walls paneled under a brick. This species has only recently begun to gain popularity among consumers.

The basic concepts of installing panels yourself

To begin with, you need to acquire auxiliary tools, namely:

- hacksaw on wood,

- drill,

- screwdriver it is much more convenient than a screwdriver,

- scissors to cut metal,

- hammer,

- building level,

- tape measure,

- stepladder.

Wall finishing with wall panels is carried out only after the surface is leveled and cleaned of paint and dust. First you need to measure the area, where later the installation of the coating will take place.

Proceed to install the system when all the fittings are already attached - internal and external corners and ceiling skirting.

Installation of panels horizontally occurs from the bottom to the top. Fix plates with screws, nails or special glue.

If there was a need to change the dimensions of the plate, then use scissors or a hacksaw.

Wall paneling allows you to carry out any design of your house. Relying on your own taste and imagination, you can get a pretty trendy interior.

Photo of wall paneling

In search of original solutions for the decoration of walls and ceilings in a living room, some choose their decorative panels. Such material can serve as an element of decor, and the basic finish. There are many types decorative panels, which in most cases are characterized by high moisture resistance, heat resistance and sound insulation.

If you have not decided on the choice, it is worth to learn some of the advantages of this technology for facing the walls. Decorative panels for interior decoration of walls perfectly hide all the irregularities. This allows you to save when performing finishing works, namely, on leveling the walls plaster mixtures. This article will discuss various options for decorative panels, the installation of which can be carried out in the kitchen, bathroom, hallway and even a living room.

Types and characteristics of decorative wall panels

Wall facing panels in contrast to other finishing materials have a lot of advantages. For their installation, there is no need to level the base. In a short period of time, you can process a large area of the wall. On the market, they are represented by many different shapes, sizes, textures and colors. Thanks to this, you can choose those panels that best match the chosen style of the room.

There are three main types of decorative panels:

- Rack.

- Leafy.

- Tiled.

Rack. Their fastening is carried out with the help of special staples. The width of the product can vary between 13.5-30 cm, the length is 0.9-3 m, and the panel thickness is 8-12 mm.

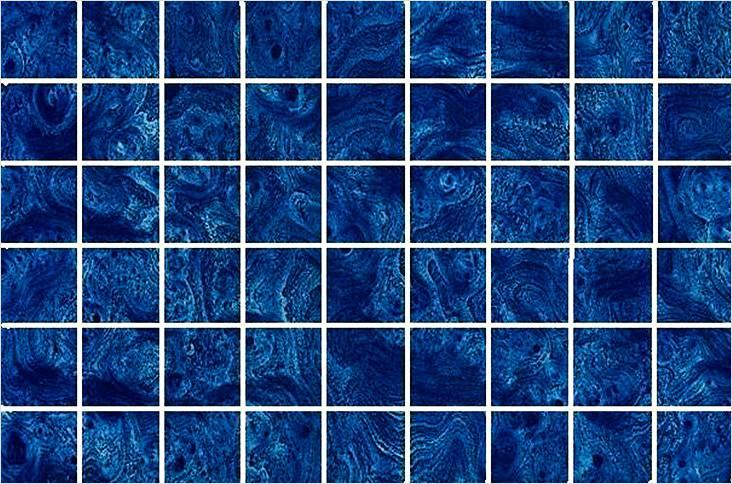

Tiled . The shape of the plate is square. Standard sizes tiles 30 × 30 and 90 × 90 cm.

Sheet . Reminiscent of a sheet plywood, on top of which a pattern is applied. The thickness of such a panel varies from 3 to 6 mm, and the dimensions are 1.22 × 2.44 m.

For their production different materials are used:

- Polyvinyl chloride.

- Wood-fiber board.

- Wood particle board.

- Bung.

- Tree.

- Gypsum.

If we talk about the positive aspects of decorative panels, here we can distinguish the following:

- Quick and easy installation. When fixing wall panels there is no need to pre-prepare the walls. For their installation it is enough to have nails, glue, wooden bars, a stapler and other fastening material.

- Versatility. In addition to the decorative role, they can serve as a thermal insulation and soundproofing.

- Easy to clean. It is enough to wipe the surface of decorative panels from time to time with a damp cloth.

- Saving. In contrast to the use of other finishing materials, wall paneling panels - an economical option.

- Design solutions. Decorative panels can be glued in different directions, for example, vertically, horizontally, diagonally and even a diamond.

- Durability. The surface of panels is resistant to mechanical influences.

Wooden panels

Decorative panels for facing the walls of solid wood are one of the popular finishes. Although there are many alternative options, this material does not lose demand. This is explained by the fact that it is environmentally friendly, and the texture of the tree conveys a special mood to those around it. Moreover, no material can successfully imitate the structure of wood.

They can be installed in almost any room: residential apartment, living room, restaurant, office. Plus, their installation is quite simple.

It is worth noting that the appearance depends on the method of processing the upper layer. There are several methods for processing decorative panels:

- Varnishing. The varnish allows the wood to become more moisture resistant and have a more attractive appearance.

- Lamination. The surface of the wood is glossy, plus to this, it acquires additional protective properties.

- Veneering. On the tree is applied veneer of valuable species of natural wood. Such panels have a beautiful appearance.

Connection method

Two methods of fastening are known:

1st method - groove-comb. In this case, dense joining of all elements is ensured. Also, this method of connection allows you to create a single picture.

2nd method - groove-groove. With this method of joining, the colors and the shading will not coincide.

In addition, wooden decorative panels are decorated with skirting boards, slats and fillets.

Types of wood

For the production of such panels wood of such tree species is used: pine, cherry, beech, ash, spruce, cedar, alder, oak, maple. Each wood has its own unique texture. It is possible to combine several woods in one panel, overlaying it with layers. For this purpose, there is a special technique where layers of different types of wood are reliably fastened under high temperature and pressure.

Types and Distinctions

Today there are several methods of manufacturing decorative wood panels, which are presented in the table:

|

|

Multilayered wood panel is the most common. The top layer is made of veneer of expensive wood, and the middle layer is made from less valuable wood. In appearance they completely resemble solid wood. |

|

|

The glued panel. Applied coniferous trees. With success copes with the humid atmosphere. Fungi and mold are not formed. |

|

|

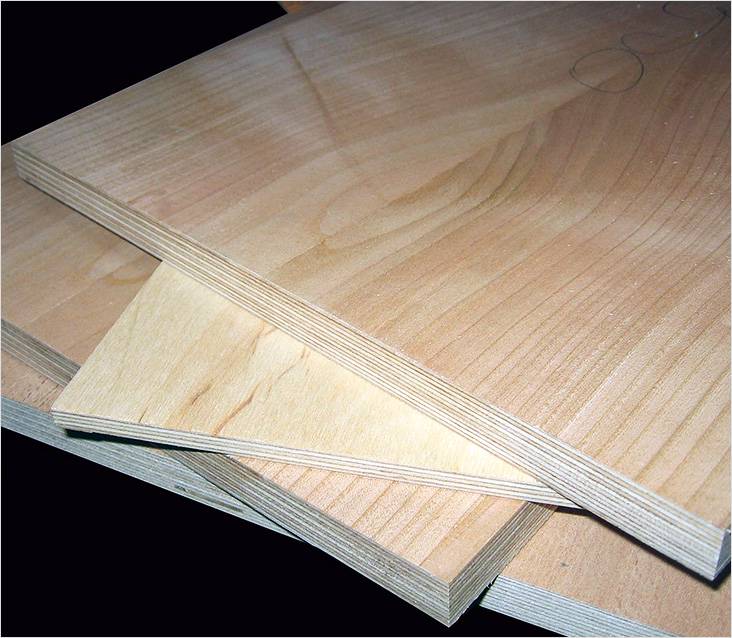

Glued panel made of veneer. The product consists of several layers of thin veneer, which are glued together. To make the workpiece of high strength, the layers are glued perpendicular to each other. Unlike a solid array, the cost of a glued panel is much lower. Most often this panel is used for finishing the ceiling surface. |

|

|

Veneered chipboard. The top layer is made of natural veneer, and the inner layer is based on chipboard. The blanks are heavy, so they are rarely used. |

|

|

One-piece array. This is the most expensive material for decorative finishes walls. The pattern and texture correspond to the selected wood species. |

Benefits:

- Lovely appearance.

- Ecological compatibility of the material.

- Promote heat savings.

- Durability.

- Simple installation.

- Easy to process.

- The ability to hide certain communications.

- After a while you can repaint.

Among the shortcomings is:

- Low level of moisture resistance.

- High risk of fire.

- High cost of decorative panel.

Panels from MDF and chipboard

The material of chipboard and MDF differ by production technology. Unlike chipboard, MDF decorative panels are much more qualitative. This is explained by the use of high-quality binding agents in the production of MDF.

To make it easier to make a choice, considering all the features of the material, we compare MDF and chipboard among themselves according to several criteria:

|

Characteristics |

Comparison of fiberboard and MDF |

|

Security |

In the EAF, harmful binding resins urea-formaldehyde and phenol-formaldehyde are used. Even in small amounts, they can negatively affect the human body. MDF panels, in turn, are made of natural materials. |

|

Moisture resistance |

Both MDF and chipboard are coated with special water-repellent compounds. However, as a result of prolonged exposure to moisture, these materials begin to deteriorate. The only difference is that the chipboard swells and deforms faster than MDF. |

|

Treatment |

The surface of the chipboard is uneven and porous. Therefore, for its painting, it is necessary to pre-process its processing and polish. As for MDF panels, their surface already has a special coating, so they are ready for painting and other processing immediately. |

|

Fire hazard |

MDF has a low level of resistance to high temperature. |

Features of decorative MDF panels

MDF panels are obtained due to the method of dry pressing of sawdust. The material is processed under high pressure and temperature. To make the material very high quality and resistant to wear, carbamide resins are added to it.

Panels made from MDF have such advantages:

- Simple installation.

- Do not require special care during operation.

- Before installation, there is no need to produce a serious surface preparation. The condition of the walls does not affect the quality of the finish.

- The ability to mount panels in any direction: diagonal, across or along the wall.

- Formed sub-panel space after installation works can be used for laying communications, for example, electrical wires, the Internet and other things.

There are 3 types of MDF panels:

- Whole-pressed.

- Laminated.

- Moisture-proof.

They differ in production method, technical characteristics and decorative properties. For example, all-pressed plates have a smooth surface on both sides. Laminated are characterized by the fact that the front surface is covered with a thin polymer film. Due to this, resistance to mechanical stress, moisture, etc. increases. In this case, the film can have a variety of colors and design.

As for moisture-resistant MDF panels, their production is made of a denser material. The basis is high quality wood. Because of this, these panels are used for finishing bathrooms, loggias, balconies and other rooms with a high level of humidity.

Decorative panels from MDF also differ by the method of registration of the front side:

- Painted. The rough surface is treated with a special paint, which smooths out any irregularities and gives the product a glossy or matte look.

- Glossy. The front side of the product is laminated with a transparent polymer film.

- Veneered. They have the texture of real wood. This effect is achieved by applying a thin layer of wood veneer, up to 3 mm thick, onto the MDF surface. In this case, you can use ash, oak and other tree species.

Features of decorative chipboard panels

Particleboard is obtained by pressing chips, which is mixed with thermosetting resins. Its main advantages are:

- Resistance to mechanical influences.

- Strength.

- Low index for sound and heat insulation.

- Easy to process.

- Low cost.

- Simple installation.

Sheets of chipboard are covered with veneer or laminated with a special plastic. Several of their varieties are known:

- Matte coating. The design is applied to natural stone, wood textures or textiles.

- Glossy surface. The design is applied to imitation wood, stone, tile, marble and even plant patterns. As a coating, a special finish film, covered with varnish, can be used. It is resistant to scratches and abrasion.

Also it is worth highlighting several varieties of decorative panels made of particleboard:

|

Rack |

The panels are connected by the technology of the spike-groove, and the nails are fixed with nails. This finish will withstand the weight of suspension accessories, shelves and other products. The dimensions of the product vary within the following limits: thickness 12 mm, width 12.5-30 cm, length 2.4-3.7 m. |

|

Tile |

To the wall are attached to the rack frame by nails, self-tapping screws or with the help of special glue. The dimensions of the decorative panel range from 300 × 300 to 980 × 980 mm. |

|

Sheet |

To the wall are glued with special glue or screwed onto the frame with self-tapping screws. The thickness of the decorative sheet panel chipboard - 6-8 mm, length - 1,22-2,44 m. Additionally panels are finished with profiles, cornices, decorative corners and the like. |

|

Skinali |

Mainly used for arrangement kitchen apron. When it is produced, a moisture resistant board with a finishing coat of 6 to 12 mm is used. Considering the peculiarity of the coating, the holes for the sockets and other communications should be carried out very carefully. |

Plates of chipboard are produced with different markings and classification by quality:

- E1. Such plates contain not less than 10 g of free formaldehyde per 100 g of dry chipboard. Such indicators are allowed for the production of furniture in the nursery.

- Y2. In such a material, there may be 100 g of dry particleboard from 10 to 30 mg of free formaldehyde. In this case, the use of such plates for the production of furniture is prohibited.

- Super E. The plate of this classification is extremely safe. They are recommended to be used for decoration of living quarters, children's rooms and furniture production.

Panels from fiberboard

Fibreboard means a fibreboard. Its production is carried out on the basis of wood waste. In the composition of the material, various components are necessarily added. In appearance, they resemble ordinary pressed cardboard. There are 2 types of decorative panels of fiberboard:

- Tough.

- Soft.

Rigid hardboard

Excellent cope with mechanical stress and resist abrasion. Based on these technical characteristics, they are mounted on the balcony, toilet and corridor.

The presence of a polymer film on the panel allows wet cleaning, even using detergents with the presence of chlorine. Under the influence of ultraviolet rays, the color of the panels does not change. Therefore, after a while, the panels of the fiberboard will remain unchanged.

Based on the design idea, decorative panels of fiberboard can have different coating: gloss, matte and textured.

Soft Fibreboard

Visually similar panels are no different from hard. The difference in the methods of their production, as well as in technical characteristics. Their production is carried out exclusively from softwood. As a binder, lignin, a special polymer compound, is used. This substance is extracted from the juice of resinous wood. Such panels are considered environmentally friendly.

Although this type of fiberboard is soft, it has excellent thermal insulation and soundproof properties. The panel thickness of 12 mm is equal to the wooden board in 450 mm.

Soft cover layer can be different:

- Vinyl cover resembling wallpaper.

- A layer of natural cane or a linen covering.

- Acrylic waterproof coating.

There is a huge opportunity to choose any colors, imitations and designs of decorative panels of fiberboard.

Installation is carried out in the following ways:

- For fixing to the wall - special glue.

- To the wooden crate - with the help of staples and small carnations.

Video, which compares MDF, fiberboard and chipboard panels

Panels from PVC

Decorative panels made of PVC are the most practical and popular. This material is used for facing the walls of the bathroom, verandas, saunas, balconies and other premises. The composition of this panel includes vinyl chloride polymer. Due to this, the material is resistant to chemical influences, such as solvents, acids, alkalis, mineral oils.

There are several types of PVC panels:

|

|

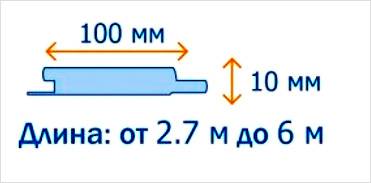

Narrow oblong lining. Length 3 m, width from 30 to 60 cm. |

|

|

Tile panel. |

|

|

Square PVC panel. The size of the sides can reach 100 × 100 cm. |

|

|

Among the positive aspects of this type of decoration can be identified as follows:

- Moisture resistance.

- Durability.

- Resistance to temperature changes.

- Resistance to ultraviolet.

- Safety during operation.

- Soundproofing.

- Simple installation.

When buying PVC panels, pay attention to their appearance. The image should not be damaged, and the panels themselves must be unbroken without any chips.

As for the fixing method, several methods are known:

1 method: on the glue.

2 method: on self-tapping screws or nails.

3 method: with clamps.

4 method: Staples.

As for the first technique, it is mainly used for mosaic PVC panels. Plus, this method of installation is considered the fastest and cheapest. In all other cases it is necessary to build a metal or wooden frame. If a premise with high humidity, wood should be treated with special compounds, however, it is recommended to collect a metal frame.

To finish the bathrooms often use mosaic panels. You can see the prepared video about the wall covering with plastic wall panels in the bathroom:

The thickness of such a panel is about 1 mm. If there are columns in the interior of the room, then similar folding panels will easily give them a finished look. They are used for finishing the ceiling, walls and work surfaces.

Below in the table, several types of mosaic panel and approximate prices are given:

Dimensions of PVC panels

Depending on the type of decorative plastic PVC panel, they differ in their size:

Connection type

The panels are divided into several groups:

- Relief.

- Seamless.

- Having chamfer or rust.

Seamless PVC panels are ideal for finishing the ceiling. Due to a special connection, the joint is almost invisible. With a chamfer resemble the method of joining seamless panels. However, there is a facet in the end part. Under the roof is meant a decorative depression. They are used for finishing the ceiling / walls.

Mostly for the walls, relief panels are used. In appearance they resemble a lining the cost of a relief lining is much higher.

Choosing a quality PVC panel

Given that the market has a large number of poor-quality materials among PVC panels, it is important to know what to look for. Even expensive goods are not always the best. There are a number of requirements in this area, which are presented in the table:

|

Options |

Specifications |

|

Thickness |

It is believed that high-quality PVC panels should have a thickness of at least 10 mm.

It is known that the panel, which has a large thickness, is capable of withstanding a large load. If it is a ceiling finish, the thickness may be slightly less than 10 mm. |

|

Thickness of the front surface |

This indicator determines the ability of the panel to withstand a certain load. For example, it is able to prevent punching, withstand mechanical stress, shocks and so on. Pay attention to the fact that if on the panel through the front side the stiffeners are visible, this indicates its low quality. Therefore, on the ceiling and, especially on the walls, it is not recommended to install it. However, many may be tempted by its low cost. |

|

Stiffeners: stiffness, location, number |

Here everything is simple: the more the panel of stiffeners will have, the better it is of quality. This also affects the resistance of the product to mechanical stress. |

|

The distance between the stiffeners |

Between the stiffeners in the panel should be no more than 10 mm. If the distance is large, the risk of dent formation is very high. Accordingly, after mounting such a panel, all dents will be seen clearly. |

|

Coloring |

Special attention is paid to the method and quality of PVC panel painting. Some manufacturers do not add any color pigment to the polymer mass when staining. As a result, this can lead to the formation of scratches, which will be very visible. In addition, under the influence of ultraviolet rays, the color of the panel will burn out. |

|

Toxicity |

Installation of PVC panels in a residential building requires compliance with safety rules. Therefore, before buying, ask the seller to provide you with a quality certificate. Some manufacturers use toxic substances in production, which can adversely affect health. It is worth noting that when unpacking panels can have a specific smell. But if this smell has a panel that has been used for some time as a sample - be careful! |

|

The more the number of stiffeners and the thickness of the front side, the more weight the PVC panel will have. If we talk about the standard weight, it fluctuates around 1.5 kg / m 2. However, this is a conventional indicator, as much depends on the size and type of the decorative panel. |

|

|

Docking |

Be sure to make sure that the connection method used in the selected panel is reliable and of high quality. |

|

The presence of chalk |

Quality panels should contain no more than 20% chalk. The higher this value, the higher the fragility of the material. Therefore, some unscrupulous producers add this component more than necessary to save. Check the level of chalk in the plastic panel is very simple. Slightly bend the corner of the panel. If a crack or white strip appears, the amount of chalk exceeds the standard. If the panel is plastic, then it can be bought. |

|

Manufacturer |

Try to give preference to proven manufacturers who have proven themselves on the positive side. Verify this will help you feedback on the forums about this or that material. |

Gypsum boards

Gypsum decorative panels replaced the plaster moldings. Moreover, they completely replaced the stucco molding, since this method of surface finishing is suitable only for classic design. Using this material allows you to create corrugated surfaces, giving this or that room a beautiful appearance.

Among the advantages of gypsum decorative panels are the following:

- Easy installation. Gypsum is easily fixed to both horizontal and vertical surfaces. In the production strict geometry of all details is observed, thanks to this the resulting result will please the eyes of aesthetes.

- Long service life. Gypsum itself is resistant to all sorts of mechanical and other types of influences. Moreover, gypsum panels easily cope with a small amount of moisture that has fallen on them. They can easily cope with sharp temperature changes.

- Light weight. In the production of gypsum panels, a lightweight gypsum is used. As a result, the installation process has no additional complications. In addition, walls or other surfaces do not experience additional stress.

- Ecological compatibility. The production of gypsum panels completely eliminates the use of harmful substances. Therefore, this facing material is suitable for living quarters, including a children's room.

- High level of sound insulation. Extraneous noise from neighbors or from the streets will not bother you.

- Cost-effective. This material can simulate rather expensive analogues, such as wood, stone, brick and so on.

- Heat Saving. The available heat inside the room will be better kept if the walls are faced with plaster panels. Moreover, if the walls are thin, then the use of this material improves the quality of insulation, and a pleasant microclimate will be created indoors.

- Low combustibility. In the composition of gypsum panels there are no flammable elements. Therefore, their use is safe.

Thanks to the availability of modern equipment, it is now possible to produce gypsum panels of various shapes, designs and sizes. For example, oval, round, square, rectangular and other panels are known.

Depending on the type of gypsum panel, they can have different sizes. For example, the size of the square panels can vary within such limits of 0.2 × 0.2 m - 0.9 × 0.6 m. The thickness of such elements also varies from 18 to 36 mm.

One of the main advantages of gypsum panels is the possibility of repeated staining. Therefore, if the walls in your room are treated with gypsum panels, after a while you can change their coloring without any difficulties.

Video about gypsum panels

Cork Panels

Cork decorative panels are light and durable material, which is made from cork cork. By type, the material is presented in the form of a compact compressed mass having two ground surfaces.

This type of finish has its bright advantages and disadvantages, which are presented in the table:

|

Advantages |

disadvantages |

|

Easy installation |

If the plug jams, it does not immediately return to its original form. |

|

Ecological compatibility. Cork has the property of delaying harmful emissions. |

If dents are formed during the operation in the plug, they are not restored. |

|

Hygiene. The special structure of the finished cork does not contribute to the accumulation of dust, moisture and dirt in its structure. |

Does not have high thermal insulation properties. This parameter can be compared with a wall carpet. |

|

Soundproofing. |

Only glued tiles from the cork can not be moved. Therefore, everything must be done in an accurate manner. |

|

Vibration isolation. |

High price. |

|

Water resistant. |

In inaccurate treatment can break through. |

|

Eliminates the formation of mold, but the plug itself does not rot. |

|

|

Durable. |

|

|

Resistant to ultraviolet rays. After a while, does not change its color. |

Wall decorative cork panels are used in a variety of rooms:

- In the office.

- In the living room.

- In the children's room.

- In the kitchen and other rooms.

Although its cost is high, it fully justifies itself, as this wall decoration will last for many years.

Types and classification of cork panels

There are several types of cork coatings:

- Rolling shutters.

- Leafy. Can take the form of a square and a rectangle.

As for the leaf, they are of two types: compositing and tiling. In the case of dials, they have a width of 100 mm, a length of up to 6 meters. Tiles also have different sizes from 300 × 300 mm and up to 980 × 490 mm. Given this diversity, you can create a variety of interior design elements that will delight your eyes.

Also, the cork panels have different classification for use. For example, they can be used for finishing the floor, walls. There are insulating panels made of agglomerate. In order to increase the noise insulation properties, the cork is used as a technical coating.

Some cork panels are made moisture resistant. They are faced with a double-sided laminate coating based on PVC, fiberboard, MDF. Based on the chipboard, the cork panels are not waterproof.

To quickly and effectively decorate the walls today, 3D wall panels are widely used. Thanks to this, you can create a variety of subjects, combinations and so on. You can combine the decoration with furniture or other elements of the interior.

Wall 3D panels have a lot of advantages, unlike their counterparts. All positive characteristics of this facing material are set forth in the table:

|

Easy installation |

There is no need to create a perfectly flat surface of the wall. Minor flaws can not spoil the overall appearance of the finish. There is a technology of mounting on the frame. In this case, it is enough to produce a rough finish, and then install and secure the frame. |

|

Easy operation |

During operation, 3D panels can be cleaned with ordinary household products. If wood or gypsum was used as material, they will need more thorough care. |

|

Ecological compatibility |

To create 3D decorative panels you can use natural materials. For example, beautiful look bamboo or other types of panels. |

|

Increasing the thermal insulation of walls |

Mounting the 3D panels on the wall surface increases the soundproofing properties. If you build a frame and put a heater in the space between the wall and the panels, the level of sound insulation will be even higher. |

|

Soundproofing |

Especially this property is allocated 3D panels from gypsum. As a consequence, the level of comfort is significantly increased. |

|

Correcting the size of the room |

Using 3D panels, you can create various effects, for example, visually expand the room or raise the ceiling. |

|

Ability to combine with other materials |

The advantage of 3D panels is the ability to combine with other types of cladding. Thanks to this, special plots, textures and a range of colors are created. |

Types of 3D panels

A variety of materials are used to make 3D wall panels. Each of them has its own technological features:

- Gypsum. The material is relatively fragile. After installation, all joints are filled with special putty. The surface of the panels can be painted in any color. If there is a high humidity in the room, it is not recommended to fix 3D panels on the walls. By itself, gypsum increases the heat and sound insulation properties of the wall. In addition, this material is not burned, so they are often used for facing fireplaces.

- Metal. In addition to decorative properties, such panels are distinguished by their high strength, reliability and safety. Such panels are mainly made of aluminum and its alloys. The planned volumetric drawing is applied to them by the perforation method. The workpiece is treated with a protective polymer film. So, we can single out several positive properties of such a finish: moisture resistance, corrosion resistance, fire safety. The panels are mounted on a prefabricated frame.

- Glass. In this case, glass thickness of 0.5 cm is used. Glass is strong enough. In case of its destruction, it does not form sharp fragments. A similar structure of the glass in the car.

- MDF. Products are characterized by high moisture resistance, as the front side is covered with a special polymer film. It also promotes continued exploitation.

- Plastic. The basis is the polymer materials. In their functions, such panels are similar to aluminum ones. Thanks to them you can create different pictures, as well as select different color solutions. Plastic 3D panels are resistant to sudden changes in temperature. The material itself is ductile, light in weight and durable. Moreover, plastic allows you to realize the most complex patterns.

- Wooden. These are the most expensive 3D panels. However, their high cost completely pays off with their beautiful appearance. They are distinguished by their exquisite design and at the same time sophisticated execution. In this case, the panels have a sufficiently large weight.

Video about using wooden 3D panels

Acoustic

As acoustic panels a special soundproof material is used. It is installed in apartments, cinemas, professional studios. They are made from the most diverse different materials, each of them gives the product special technical properties.

Among the positive aspects can be identified as follows:

- A variety of sizes.

- Ecological compatibility.

- Efficiency.

- Excellent sound insulation.

- Variety of colors and styles.

They are made of various materials, both hard and soft. Very often they are based on MDF, fiberglass, plastic, wood, foam rubber, etc. Their installation can be carried out on the ceiling and walls. The surface of the panel is corrugated and smooth. In professional studios, the corrugated ones are predominantly used. They contribute to the absorption of all unnecessary and extraneous noise. Such panels improve the quality of recording.

How to choose

Mainly, it is necessary to determine the place of use of certain panels. For example:

- Glass will look great in the kitchen or bathroom.

- Wooden in the bedroom and living room.

- Gypsum in the big hall.

Also, when choosing, pay attention to the dimensions of the panels. Thin and long panels visually expand and extend the room. If the panels are large, they will look great in large rooms.

Important important parameters are taken into account:

- Toxicity.

- Smoke formation.

- Ignition.

- Flammability.

You should choose those products where the level is the lowest and is designated "1", for example, the combustibility of G1, the toxicity of T1, etc.

In addition, pay attention to the integrity of the packaging and panels without it. There should be no defects and all kinds of damage. The edges, corners and surface should not have any flaws. Protective coating should not have scratches and blisters. If you buy one lot, then the color of all panels must match.

Price list

Of course, the main criterion of choice has always been and remains the price. Most people who start repairing, first of all, assess their budget. On Russian market There are various finishes available in different price categories. With the most common models of wall decorative panels you can find in the table below.

Decorative plating of surfaces in rooms - important stage construction or repair, and you can choose for this, different materials, for example, MDF wall panels for interior decoration. But there are other options, which we will consider below.

1

We will not consider wallpaper here, although such a decision begs in the first place. We are more interested in decorative panels. Since ancient times, in the stone houses, the walls were covered with fabric, which was the simplest solution, but wood panels were the most successful. Ordinary smooth ones could be seen in the dwelling of a person with moderate prosperity, and the carved ones already spoke of a high status. Today, both options are completely accessible to everyone, in addition, there are also 3D panels made of natural wood. Also quite popular are panels made of MDF, fiberboard and even chipboard, although the latter belong to the economy class and do not have high decorative properties.

Room after interior decoration

Budget plastic plastic wall coverings are used, which are usually made in the form of narrow long strips. As a rule, polyvinyl chloride or, in other words, PVC is used as a material. Less known glass panels, which for decorative purposes are made in the form of stained glass. This option is quite expensive, but with careful installation is durable. It is worth mentioning and 3D-coatings, which are made of various materials, including natural wood and MDF. Quite expensive and therefore not available to all bamboo wall covering. Even more rarely in residential areas, the walls are covered with aluminum panels, which often have a relief or perforated surface.

Today the fashion includes a new material for finishing the surfaces in the house - gypsovinil, related to plasterboard, but having a decorative vinyl layer. This option is not too expensive, and therefore quite suitable for experimenting with it. And, finally, we mention such a type of skin as soft panels. They are interesting in that they can be used for practical purposes, for example in a bedroom, such a cover will serve as a ready headboard for a bed, and in the living room for an ottoman without a backrest. And the most rare material in use - stone veneer. We will talk about it separately, since such panels are not widely available on the market.

2

Many have some prejudice against such materials and are often not in vain, since the quality of pressed boards from shavings or shredded wood fiber shields is different, including mediocre. Particularly, chipboard made of sawdust connected with a binder is very vulnerable to moisture and therefore it is not worthwhile to use them in the bathroom or near it. In addition, the strength of such panels leaves much to be desired, while processing their structure is easily destroyed.

Fiberboard for wall finishing

Therefore, walls are covered with such sheets, usually in those cases where an economical solution is required. However, the fragility of the material is compensated by the rich palette of the outer layer, as well as by the large number of beautiful textures. But it is better to cover them with walk-through rooms. Fibreboard is much safer for the simple reason that for the production of such panels, chopped wood fiber is used, and not shavings with sawdust. In addition, there are separate brands that can withstand a long time the effect of moisture, without swelling or jostling. Decorative wall panels made of fiberboard are very often used for interior decoration of walls in living rooms, because they fully correspond to wood, but are cheaper and often have a beautiful terrain, including 3D. But for the bedroom this option is not very good, you can use such plates in the living room, office, library, dining room.

In principle, moisture-proof series is quite suitable for the kitchen, but in the bathroom they should not be mounted, enough high concentration of steam in the air, so that the skin is swollen and exfoliated.

The most durable and reliable option is, but it is also the most expensive of pressed materials, since such sheets have a very high density of fibrous structure. What is noteworthy, this type of wall coverings is best treated, and that's why surface slabs with complex relief (in particular - 3D) or even carved ones are made on the basis of MDF. Installation is allowed in all living quarters for the simple reason that the binder is lignite, which is contained in wood fibers and is released when pressed under high temperatures. That is, you can cover the walls with such panels in the bedroom. Moisture-proof series are great for the kitchen and even for the bathroom with a high-quality hood.

3

Due to its popularity and prevalence, this material is not inferior to pressed slabs, since it is approximately in the same price category. Of course, there are both budget series, and very expensive. The price depends for the most part on the number of stiffeners connecting the front and back sides of the hollow sheet, and also on the thickness of the material. Affects the cost and design of the decorative layer, the complexity of the texture. Well, of course, the popularity of the brand, although some eminent manufacturers produce quite affordable series.

Finishing the balcony with plastic panels

However, unlike pressed wood boards, plastic sheets are not suitable for all premises, in residential rooms they are usually not used and are very rarely used in hallways. Basically, this cladding is installed in the bathroom, less often - in the kitchen and the loggia. The main advantages of PVC– in the environmental friendliness of the material, because of polyvinyl chloride and food packaging, and water pipes, as well as in the resistance to heat. If the chipboard and fiberboard are already burning at 250 degrees, the plastic panels withstand temperatures of up to 370 degrees.

But even when they are on fire, they emit relatively little smoke and toxic substances, in contrast to pressed plates. It is very easy to fasten the PVC lining due to special locks, especially if you use rails. Having done everything correctly, you will get an excellent and inexpensive moisture resistant coating for the walls of the bathroom or toilet. The disadvantage of such a material is its high brittleness, a sufficiently low impact, so that a noticeable deformation appears on the surface.

4

This type of wall coverings is rather unusual for living quarters, as it is used more often in public places, for decorating halls of restaurants and cafes, foyer of theaters and museums, business center lobbies. That is, in fact, glass panels are usually used in commercial buildings. But in living rooms with the help of such a finish, you can create a very original design. The choice for today is quite rich: painted with casting or only on the back side of glass, triplexes with images inserted inside, and also decoctryl. The latter is a polymer of varying degrees of transparency, it is more durable, but less resistant to scratches.

Example of decorative glass panels

In addition, there are other versions of glass panels, for example, with patterns and complex images made by sandblasting the surface. Also there are models engraved or with complex cast relief. The latter look particularly impressive in the form of stained glass, when the image is combined with an appropriately executed texture. And, finally, an interesting option with photoprinting, when the glass with the applied pattern is baked by ultraviolet, and then subjected to heat treatment, so that the paint is sintered with glass. To protect the decorative layer from damage, panels are often varnished or laminated. Resistance to corrosion allows these panels to be used in the bathroom and in the kitchen.

Now let's look at the ways of fixing the panel for the walls. First of all, of course, gluing is a fairly common option, but it requires careful leveling of the surface. Another quite affordable way is for profiles or crates. Bolting fasteners are also often used. Another type of installation - cutting down a shallow recess in the wall to the size of the panel, installing a special box to strengthen the glass in it. The simplest solution is to hang the decorative plate on the wall, like a picture, that is, either in a frame, or as it is, with a loop fastener to the glass. Such methods are suitable for decorating walls in both the living room and the bedroom.

5

Sometimes it is necessary to do repairs in the house quickly, without spending extra time for finishing work. In this case, panels are needed. In particular, gypsum board can be replaced with a similar material, in which the outer protective surfaces are not made of cardboard, but of vinyl sheets. That is, the principle of installation is the same, but you eventually get a finished room immediately after the completion of the walls.

Gypsum plastering for walls

It is noteworthy that such panels have a lot of different colors and their shades and as many patterned textures (including wood), which will create any design in the room. And gypsovinil is good not only as a wall covering, but also for the construction of partitions, when it is necessary to divide a room of a large area into several parts. A similar solution (using panels as a partition) is suitable for an attic or for separating a small study from one of its corners from the large living room. Also with the help of gypsum, it is easy to equip a separate dressing room in the bedroom.

The thickness of the material is usually 12 millimeters, the dimensions can be different, like 2.5x1.2 meters, and 0.3x1.2. It should be noted that the fire hazard of the material is average, but the smoke formation is very low, while the smoke has a slight toxicity, which allows the use of such panels for finishing the sleeping rooms. Due to the polymeric decorative layer, gypsum is quite resistant to increased humidity, but for the bathroom it is still not suitable.

6

Until recently, such a skin was at the height of fashion, popular it made the novelty. However, even today it is a rather unusual way to decorate a room, which, however, is accessible to many. Of course, it all depends on what material the 3D panels are made of. If it is MDF, the cost will be relatively low, but bamboo sheets or coatings made of natural wood will be quite expensive. If you remember about glass and aluminum panels, then these options can be attributed, rather, to elite sheathing materials.

Using 3D panels for decoration

By the way, there is another, quite budgetary option - gypsum boards, reinforced inside a steel mesh, they are not very strong, but can have a complex relief of the front surface. MDF can only be the basis of 3D plating, and the decorative layer is often made of the same plaster and plastic, and on top is covered with enamel or thin PVC film for greater durability. Mounted 3D covers can be on special profiles, like gypsum plasterboard, also some models are supplied with locks for connection to the guides of the pre-installed frame.

Also excellent for installation is a crate of wooden beams. Another way - glue, which is suitable for almost all skin materials, provided that the wall surfaces are perfectly even. On bolts such panels are planted very rarely, mostly only aluminum ones, for the reason that unguarded hats somewhat damage the appearance of the decorative wall covering. All the wall such panels can not be covered, they are perfectly used as a separate element of design, for example, as a panel. Because of the high cost they are often decorated with living rooms, aluminum or glass tiles can be attached in the bathroom.

7

Earlier, we already voiced the option, when the walls in the bedroom or in the living room can be upholstered with soft panels. Now let's get to know them better. Of course, they are made of several different materials, and at the base often is a perforated chipboard or fiberboard. On top of the foam or sintepon, which also holes are cut. Then all this is covered with a dense cloth or leather, quilted, pulled to the base through the holes with large buttons - and the soft panel is ready.

Soft panels in the bedroom

Mount it best of all, of course, on the crate, screws with wide hats. And, knowing the technology, such a skin for the walls can be made independently. Sometimes one panel is enough to make the room much more comfortable. In the bathroom, it is not recommended to attach it even with leather upholstery. It is quite another matter - a stone veneer. It is a solid, but at the same time elastic material made of the finest sections of natural stone, most often slate. This cut is pasted on the fiberglass fabric, due to which, and it gets the ability to bend.

Although, of course, to fold in half or strongly bend the stone veneer does not work, on its surface immediately appears the trace of the fracture. But you can cut these panels even at home, for example, with metal scissors. On the walls they are attached only with glue, and to create a unique design in the room to cover with this veneer, you can also furniture, in particular - countertops and cabinet doors. Among other things, this material is perfectly suited for facing the bathroom, because it is absolutely moisture resistant.

Decorative panels for interior decoration of walls— This is the best option for those cases where you need to quickly transform the room with minimum costs for finishing material and on its installation.

A wide choice of such finishing material, produced from natural and artificial raw materials, allows you to choose exactly the one that fits well in price and appearance for a specific interior. Panels are easily installed on the surface of walls and ceilings and do not require long preparation before installation. These advantages, as well as the aesthetic appearance of the panels, have made them quite popular for wide application.

Decorative panels perfectly harmonize with other finishing materials, so they can be safely combined with wallpaper, close or contrasted with them in tone, as well as with painted walls.

Criteria for selecting decorative wall panels

Panels for interior decoration must meet certain requirements, so when you buy these features, you must pay attention:

- For the production of finishing material, an environmentally friendly raw materials, which in the process of operation will not be subject to the process of decomposition and allocation of hazardous substances for human health.

- Panels should be made of non-flammable and non-fire-propagating material. In addition, if an ignition occurs, it should not create smoke in the rooms. To determine how much the finishing material is safe, when purchasing it, you should pay attention to the marking applied on the package. If there is no marking of the fire safety class, and the goods are not accompanied by a certificate of conformity, then it is better to refuse the purchase immediately.

| Criteria for assessing fire hazard | Classification of the fire hazard of materials in increasing order. When labeling NG (non-combustible), there are no other properties of fire hazard | |||

|---|---|---|---|---|

| Combustibility | Г1 - slightly flammable | G2 - moderately flammable | G3 - flammable | G4 - highly flammable |

| Inflammability | IN 1 - difficult to ignite | AT 2 - moderately flammable | AT 3 - highly flammable | |

| Smoke formation during combustion or smoldering | D1 - low fouling | D 2 - moderate smoke | D3 - high fouling | |

| Toxicity of combustion products. | T1 - low-risk | T2 - moderately hazardous | T3 - highly dangerous | T4 - extremely dangerous |

| Spread Fire | WP1 - not distributing | WP2 - weakly spreading | IS3 - moderately spreading | FP4 - strongly spreading |

- The finishing material must be selected for resistance to humidity. depending on the premises for which it is purchased.

- The general requirement for all panels is strength and elasticity. When choosing, you need to consider what impact will be on the material. For example, if the panels are purchased for a children's room or a room where pets will be, then easy-care material and a strong material resistant to mechanical scratching are chosen.

- The panels should tolerate temperature changes, as some of them can be installed near the battery and the window.

- Simplicity in cleaning and resistance to detergents is also an important factor in choosing the finishing material, especially if it is installed in the kitchen, in the hallway or in one of the corridors.

- A very important selection criterion is the ease of mounting the panels.

Functionality of panels

Applying decorative panels to decorating the walls, you can not only transform the interior of the room, but also get rid of problems that can not be solved simply by gluing the wallpaper:

- For such a finish, you can hide the irregularities and other flaws in the wall.

- Behind the panels, communication trunks - cables or pipes.

- When installing the panels on the frame crate, it is possible to lay heat and soundproof material behind them. In addition, on sale there are panels already equipped with a layer of such insulation.

- Panels made of artificial materials, often very reliably imitate natural.

Video: examples of the use of wall panels for decorative decoration of premises

Types of panels in shape and material

This decorative finish can be divided into different types in the form in which it is produced, and on the materials of manufacture.

Form of issue

Today on sale you can find panels of the following release forms:

- Tile. It is made in the form of rectangles and squares of different sizes, various colors and textures. The tile is well combined with each other and with other materials, it can be used to decorate the entire wall or panel part of it.

Thanks to the clarity of the forms, this kind of decoration gives the room a tidy, leveling surface. Such panels are fastened to a lath made of wooden blocks and mounted on a wall. The size of the tile panels can vary in length from 300 to 980 mm, width from 250 to 500 mm, which makes it possible to create mosaic surfaces from them, selecting different textural patterns.

- Reiki. This kind of panels has a rectangular shape and is actually the same lining, produced not only from wood, but also from other materials, natural and artificial. The length of the rack panels varies from 2400 to 3700 mm, and the width - from 150 to 300 mm. Their minimum thickness is 8 mm, and the maximum reaches 12 ÷ 15 mm. To conceal the installation of such rails on the lath used special fasteners - clamps. These panels can be mounted both horizontally and vertically, as well as the so-called "herringbone» .

One of the most common options - panels in the form of lining

This type of panel is most often used to design rooms with a small area, since they do not visually reduce the space of the room. Rack panels are connected with each other by means of a lock "spike-groove" or only grooves, inside which special narrow tabs are inserted.

- Sheet panels produced in thickness from 3 to 10 mm and have large dimensions - from 1200 to 2450 mm. The surface of the sheet material imitates various natural textures, for example, stone, various types of wood, cork and other materials, so you can easily select suitable sheets for the interior, decorated in any style. This type of panel is most often mounted only on flat surfaces with the help of glue, but sometimes they are fastened in the same way as other types of finishing materials on the crate.

Jointly between installed panels masked by special moldings, which give the surface accuracy. These panels are produced most often from sheet fiberboard or MDF, which is decorated for various natural materials.

Material of manufacture

The wall panels themselves can be made of different materials, and in addition, the surface of many of them is additionally covered with a special decorative layer. So, in building shops it is possible to find furnish:

- From natural wood of different breeds, having a varied texture pattern.

- From polyvinyl chloride (PVC). These panels can be monophonic, or they can be applied to any pattern, textured or tinted.

- From acoustic foam rubber VS and fibers of synthetic origin, for which gypsum and polymers serve as a binder, soundproofing plates are manufactured. This kind of panels is decorated on top gypsum-fiber material or plastic.

- Gypsum-vinyl plates, which consist of gypsum closed on both sides with vinyl plates, like gypsum cardboard.

Relatively new finishing material - gypsum panels

- Cork panels, which are not only environmentally friendly finishing material, but also absorb sound well.

- Panels based on fiberboard, MDF or chipboard.

- 3D-panels made of different materials or their combinations.

Characteristics of different wall panels

To know for which room is suitable one or another type of material from which made panels, you need to consider their characteristics, as well as how they will look in the interior.

Wood Panels

Wooden panels are produced in different versions - these can be smooth square or rectangular elements having a relief pattern or assembled from several parts and having a finished appearance.

Most of the panels are made from wood of cedar, oak, larch, alder or maple. If very inexpensive material is used for their production, then they try to disguise it for more valuable wood with the help of special compounds that will make the texture more precise and darker than the fiber.

Wooden panels are ideal for decorating living quarters, as they are environmentally friendly "breathing" material. You can use them to decorate rooms with high humidity, but in this case it is necessary to choose a material impregnated with water-repellent compounds, and on top covered with wax.

Recently, panels are gaining popularity from a split wooden massif, arranged in different variations, resulting in relief drawings with a visible structure of the fibers of the material and each bough in it. This technique of making panels helps to preserve the natural beauty of the tree, since it does not show traces of processing. For the production of such boards, ash, birch and oak are used - all of them have a beautiful pattern. Finished plates are covered with colorless varnish or wax.

DSP and MDF panels

A chipboard is a composite material made from wood chips and chips. To bind these wood waste, phenol-formaldehyde resin is used, which can be from 5 to 17% of the total mass. The prepared mixture passes through the stage of hot hot pressing, after which it is converted into plates. After this, the panels are often covered with wooden veneer and laminated.

MDF - can be decoded as a finely dispersed fraction, that is, plates, are made from ofmelted lumber. Panels are formed by dry pressing, and the binder for raw materials are urea resins, which are less toxic than formaldehyde. MDF are classified E1, that is, they have the least danger to human health, which opens them to the widest application in living quarters. The remaining characteristics are similar to the parameters of particleboard.

Particleboard and MDF can be "disguised" under any type of wood, and quality material is sometimes difficult to distinguish from natural wood.

According to some characteristics, chipboard and MDF surpass even wood - the plates are strong and tough enough, but can be easily processed if necessary. Wood-particle boards have a lower classification of flammability than a natural tree, they possess sound and heat-insulating properties.

The disadvantages of conventional boards and MDF can be attributed to low moisture resistance, as they become swollen when wet, and their thickness increases by 5-30%, which leads to deformation. Therefore, this material can not be used for finishing wet rooms. However, in addition to conventional chipboard plates for rooms with normal humidity, moisture resistant wall panels are produced, but they have a higher price.

It is also necessary to know that the phenol-formaldehyde resins that make up the panels are extremely harmful to human health, and they will be released from the plates throughout the entire period of their operation. Therefore, it is undesirable to use chipboard for finishing any living quarters. Such material can be suitable for putting in order the walls of halls, passage corridors and other well-ventilated rooms. In any case, before deciding on the purchase of chipboard panels, you should familiarize yourself with their performance characteristics, indicated on the marking or in the technical documentation for the batch of goods.

The main characteristics of chipboard:

| Material parameters | Features | Use in living areas | |

|---|---|---|---|

| Classes of domestic-made chipboard for security (phenol-formaldehyde content per 100 gr of dry raw materials) | E0 | Absent | is used |

| E1 | Not more than 10 mg | is used | |

| E2 | Not more than 30 mg | Not used | |

| E3 | Not more than 60 mg | Not used | |

| Brand of chipboard | P-A | It is moisture resistant, durable and less prone to deformation. | Premises with high humidity. |

| PB | Has lower rates | ||

| Density, kg / m³ | very small | 350-450 | |

| small | 450-650 | ||

| mean | 650-750 | ||

| high | 750-800 | ||

| Grading according to GOST 10632-89 | 1st grade | Laminated. Do not have external flaws, in the form of chips, scratches, uneven edges and surfaces. | is used |

| 2nd grade | Has an external coating. On the material defects in the form of small chipping of edges, scratches and other damages are allowed. | ||

| 3 grades | Coated and without it. It is considered a defective material, it is used as an auxiliary material, for example, for the manufacture of formwork. | Depending on the amount of formaldehyde content | |

| Standard slab sizes, mm | Length | 5680, 5500, 5200, 4100, 3750, 3690, 3660, 3600.3500, 3220, 2840, 2800, 2750, 2700, 2600, 2500, 2440, 2040, 1830 ± 0.5 mm | |

| Width | 2500, 2440, 2135, 2070, 1830.1800, 1750, 1500, 1250, 1220 ± 0.5 mm | ||

| Thickness | 28, 22, 19, 18, 16, 10, 9, 8 ± 0,3 mm | ||

Here it is necessary to note that the EAFs produced abroad have different standards, and they are especially different in formaldehyde content. For example, according to European standards, the maximum permissible percentage of this substance for the class E1- 8 mg, E2- 8 ÷ 15 mg, E3 - 35 ÷ 40 mg, that is, its concentration is reduced by an average of 20%.

It is worth mentioning the number of layers that a particle board can have. The material is produced in one-, three- and five-layer versions, as well as in the form of plates with a special design, called "tambourate". Most often, three-layer slabs are used for panels, which consist of an inner layer of large chips, the middle one is made from small sawdust, and the top layer is one of the applied coatings.

"Tamburat" consists of outer layers made of chipboard or MDF, between which is placed cellular cardboard - it is light weight material, which has a structure like a sandwich panel.

Panels of fiberboard

Fibreboard - fibreboard plate. As its name implies, it is made of wood fibers, which are subjected to grinding, and then pressed under high pressure with each other. Previously, the same phenol-formaldehyde resins served as a binder for raw materials in the manufacture of plates. Today, well-known manufacturers of finishing material refuse these substances and switch to a completely environmentally friendly production using eucalyptus wood resins. The price for such products is much higher, but they are not harmful to human health, since they do not release toxic fumes into the air.

Advanced decorative panels from chipboard can be used for finishing any premises, including with high humidity. The composition of the finishing water-resistant version of the material, except for resins, includes water repellents, and the outer surface of the panels is covered with a polymer film, that is, laminated. This processing and makes the finishing plates resistant to mechanical, thermal influences and to moisture, significantly prolongs the period of their operation.

This is not brickwork, but a very successful imitation of fiberboard panels

Surfaces panels are decorated for a variety of materials - they can imitate natural stone, wood, brickwork or ceramic tile. Quality execution approximates the type of plates to simulated materials so that it is sometimes difficult to distinguish them from the original. At the same time, the plates have a lower price than the natural finish and their installation is much easier and faster, which allows you to create the desired design at a lower cost.

Sheets of fiberboard can have a maximum length of 3600 mm, a width of 1800 mm, and their thickness is from 3 to 25 mm. Such dimensions of the sheet allow you to close a large area immediately, which makes the installation faster and better. Panels can have different structural densities and are divided into three types according to this criterion:

Installation of fiberboard panels

Before the installation of decorative panels on the walls, they are brought into the room where they will be installed and left for several days to adapt to the temperature and humidity regime.

The connection of slabs or sheets of fiberboard and their installation in one plane, can be made in two ways:

- The most famous and simple is with the help of the lock "spike-groove".

- The second way is the "groove-groove" lock, into which the fastening tab is inserted.

As a rule, the panels are fixed on the crate of wooden rails or timber, pre-installed on the wall. Elements of the crate are fixed vertically or horizontally, parallel to each other at a distance of 400 ÷ 500 mm, taking into account the dimensions of the selected finishing plates. The panels are fixed perpendicular to the elements of the crate with the help of special metal elements - clamps, so their fastening from the outside is absolutely not noticeable.

If the wall for the installation of plates is leveled and requires only decorative finishing, then the material can be glued to it with the help of glue "liquid nails".

Gypsum panels

Gypsum-vinyl decorative plates are identical in structure to plasterboard, but instead of a cardboard two-sided surface for their manufacture, vinyl plates are used, which gives the material a higher strength and aesthetic appearance that does not require additional decorative design. The material has an affordable price and is therefore quite in demand for the decoration of walls and partitions of residential and non-residential premises.

Panels from these materials are durable and resistant to mechanical influences, as well as to detergents. Finishing is easy to put in order with the help of wet cleaning, as it has resistance to moisture and aggressive environment. Therefore, the material is used not only for mounting it on walls, but for decorating slopes of window and door openings.

Plates 2500 × 1200 and 300 × 1200 mm, 12 mm thick, are produced and have more than 150 different colors that can be combined with each other and combined with other finishing materials.

Color palette - for every taste

Most often, gypsum boards are mounted using aluminum profiles having different color solutions, so they can easily be selected for any panels. If the plates are purchased from a certain manufacturer, then the material and accessories can be selected according to the available catalog.

A very important point in the installation of this material is that it is carried out without a lot of debris and dust. It is this quality that allows you to finish in an already finished interior.

A few words about fire safety gypsum finishing material. Its combustibility is classified as G2 (moderate), smoke formation - D1 (very low), flammability - B2 (moderate), smoke smoke toxicity - T1 (low toxicity).

For the installation of gypsum, different profiles are used. For example, for wall mounting, a 60 × 27 or 27 × 28 mm PP profile is used. For the installation of partitions, the PS and PN profiles are used, and the width of such a partition is 85 ÷ 95 mm on average. Between the slabs in such a construction it is possible to lay a sound-proof material or to make a laying of communications. A ready partition can replace a full wall.

Panels from PVC

PVC panels are quite popular for putting in order the walls of residential and non-residential premises of an apartment or a private house. They are produced in the form of lining or in sheets, the width of which can be 100, 250, 375, 500 and 1220 mm, and the length is 1035, 2240, 2700, 3000 and 6000 mm. The thickness usually varies from 3 to 8 mm.

PVC panels - inexpensive, easy to install and easy to clean

By purchasing panels in sheets, it is possible to significantly simplify and speed up the installation process, since a large plate covers a large area of the wall immediately.

PVC panels are manufactured without the use of hazardous substances for human health, therefore during operation they do not emit toxic fumes into the air. The material is moisture resistant, easy to clean and not afraid of household detergents. For the finishing of walls in rooms with high humidity, special moisture-proof panels are produced, which do not require special care - they should be wiped periodically with a damp and dry cloth.

PVC panels are ideal for rooms with high humidity levels

PVC panels are produced in different colors, they can imitate any natural material (stone, wood, etc.), and in addition, they can be patterned brickwork, tiles, mosaics, etc.

Panels installed on the wall will perfectly disguise the tears in the toilet and bathroom, behind them you can skip various cable communications, and, if necessary, lay soundproofing or warming material.

PVC panels are mounted not only on the walls, but also on the ceiling, and perfectly combined with the luminaires embedded in them.

The installation of this material on a wall or ceiling takes place in two ways:

- Fastening them to a wooden crate, with the help of clamps or screws.

- Bonding on a flat surface with "liquid nails" or glue on a gypsum-cement base.

To adjust the external and internal corners of the finish, special fittings are made. It should be noted that a quality installation of this material on the walls can be carried out by any, even a beginner builder who will follow the technology, carefully draws markings and will control the horizontal and vertical installation of each element.

Qualitatively mounted PVC panels, under the recommended rules of operation and care, are guaranteed to last up to 50 years, at normal room temperature, without sudden changes in one or the other side.

Cork Panels

Cork panels are perfect for finishing any of the rooms in a residential building or apartment. Such material has many advantages over any others.

- The first and most important is the absolute ecological purity of the material.

- Appreciate the cork for excellent heat and sound insulation qualities.

- The material is characterized by high moisture resistance.

- The cork does not absorb external smells, even such strong ones as tobacco smoke and kitchen odors.

- The panels can withstand high temperatures reaching up to 350 degrees, but even when this threshold is reached, the material smoldering, but not supporting combustion. In this case, the plug does not emit a large amount of smoke and toxic substances.

- Resistance of the material to ultraviolet, temperature changes and to all types of microflora allows the material to be used for a long time, since it does not change its original form.

- Simplicity of installation of a finishing material - it is quite possible to do without additional warming and installation of a lath if the wall has an equal surface. The work on finishing the walls with a cork is not accompanied by the formation of dust and a large amount of debris.

Panels from this unique material are produced in different sizes, and tiles are usually 300 × 600 or 300 × 300 mm.

In addition to walling, panels for floors are made of the same material. They have special locking joints, due to which they form a practically seamless coating after laying.

Wall panels have a thickness of 3 mm and are produced in various shades - from amber to dark brown. These colors can easily be adapted in an interior made in any of the existing styles. If desired, you can find a cork finishing material that has colored impregnations - green, red or blue.

Installation of cork panels

Mounting the panels from the cork is done in the following order:

- Surface preparation. It will need to be well leveled - you can use a drywall for this, and then treat the surface with a finishing putty. After drying, the coatings are covered with sandpaper, which will create the required level of roughness, which promotes better adhesion of the adhesive composition.

- On the prepared wall marking is carried out. It is best to draw the entire wall into rows, the width of which will depend on the size of the finishing panels, given that they will be fastened to the back.

- Further, special glue is being prepared. It is applied to the wall with a spatula only in the place where the next panel will be fixed, since it dries very fast for the cork.

- The panel is tightly pressed against the glued area, and then rolled with a roller. Within a minute the panel should be glued to the wall.

- Then, the second, then the third and subsequent panels are stuck to the first. Do not forget to roll the surface with a platen.

- Between the panels there should not be even small gaps.

Acoustic Panels

Acoustic panels are indispensable in the fight against excessive audibility in the apartment. This finish is made for walls and ceilings from different materials, which unites one property - they all have a porous structure. It is this quality that gives a high efficiency in the absorption and dispersion of sound vibrations.

The most effective of all noise isolators is acoustic foam - it is an inexpensive and sufficiently durable material that is more affordable than others, comparable to it for soundproofing qualities.

Acoustic foam is produced in different shapes and sizes, has raised or flat surfaces. It can be combined with other materials and completely hidden from the eyes.

In the range of construction shops, there are other soundproof materials having a more rigid structure than that of foam rubber. They are convenient to mount, and they are able to eliminate noise penetration to some extent. But it is their rigidity that reduces soundproof ability, since they reflect sound well, but do not absorb it.

These materials should be used in combination with foam rubber. For example, gypsovinyl slabs are used to mask foam rubber, but if applied separately, there will be no sound insulation effect.

Sound-absorbing panels are made in relief or relief. The latter are considered a professional material, and are usually used in recording studios, in the premises located near production shops or busy motor roads.

The use of acoustic panels in apartments is not very common, but in recent years it has become increasingly popular, as the walls of multi-storey houses built of reinforced concrete panels have high sound conductivity. This factor adversely affects the psyche, preventing a person from completely relaxing and resting. Acoustic panels provide an opportunity to make a room for rest completely soundproof, but for this they will have to be installed on all wall surfaces.

Combined acoustic panels can include the same foam rubber, but on top of them are masked with perforated plastic or gypsum-fiber panels that will not reduce the effectiveness of sound absorption.

Installation of acoustic panels

Installation of foam panels is made as follows:

- If foam rubber is purchased separately and does not have a decorative coating, then it is mounted under exterior finish surfaces of walls.

- Soft plates are fixed to the surface with the help of glue. If the wall finish allows, you can use for installation of double-sided wide adhesive tape.

- On the top of the foam rubber in the recesses of its relief pattern are fixed bars or curtain profiles.

- Then they can be fastened with plasterboard sheets, PVC panels or other finishing material. It does not affect the effectiveness of the foam insulation.

- In the same order, the acoustic material is mounted on the ceiling and on the floor, and then closed on the ceiling with light panels, and on the floor - with plywood or a wooden board.

- Soundproof panels made in the form of sandwich panels, can be mounted directly on the lath.

3D panels

Recently, so-called 3D panels are gaining popularity, which perfectly fit into any interior and give a striking decorative effect. Especially it will be expressed with correctly directed illumination, emphasizing

Wall panels 3D panels in combination with a competent distribution of light create a very special interior

3D panels are made of almost all the materials already mentioned - it can be PVC, natural wood, particle board, MDF, aluminum, pressed fiberboard, gypsum.

Since the characteristics of almost all listed materials have already been paid attention, and the most popular for mounting are plaster 3D panels, their parameters and installation rules and should be considered more closely.

Gypsum 3D panels are made of fine-grained gypsum powder with the addition of special plasticizers that give the material resistance to increased humidity and allow to ensure a balanced microclimate in the room. Other positive qualities of gypsum panels include the following:

- Ecological cleanliness of the material.

- Gypsum panels are completely incombustible.

- Material liable to various types of finish decorative finishing - this is painting, plastering, veneering, etc.

- Correctly mounted on the wall material has a high strength to mechanical stress.

- The walls acquire additional heat and sound insulation.

- Panels level the wall and hide all its flaws.

- Easy to install and easy to care for.

Installation of gypsum 3D panels

Gypsum 3D panels are mounted on the wall using glue on a gypsum-based basis.