The thickness of polycarbonate - this is one of the main factors in the selection of material for the manufacture of transparent structures. Polycarbonate is a strong plastic-polymer, which is used in industrial and household construction in the form of sheets. It is transparent, practical, durable, frost-resistant. The most important role in the application is its variety. In construction, two types are used: cellular and monolithic.

Canopies made of cellular polycarbonate are light and durable.

Cellular polycarbonate: thickness

Cellular polycarbonate is a polymeric material, manufactured in the form of sheets, which have a hollow cellular structure. The product has two layers connected by stiffening ribs in the form of honeycombs. They can be from 4 to 25 mm. The larger the volume, the less its thermal conductivity.

Hence, the use of polycarbonate with a larger thickness allows you to save on the costs of heating the premises.

It can be used for the following purposes:

The layer of protection from ultraviolet is usually located only on one side of the sheet.

- 4 mm - production of advertising structures, visors, greenhouses;

- 6 - 8 - canopies, greenhouses, greenhouses;

- 10 - glazing of various surfaces, high-altitude streetlights, barriers of highways;

- 16 - 25 - transparent roofs of houses;

- 32 - roof, designed for heavy snowfalls and gusty winds.

Panels made of cellular polycarbonate do not break, they do not form sharp fragments, unlike glass. They withstand severe frost, significant heat, snow and wind loads. The air layer is an excellent heat insulator. Excellent light transmission, meets the requirements of fire safety, belongs to the category of low-combustible materials.

Monolithic - is a product with higher strength and not having voids inside. Its width is from 0.75 to 4 mm. Under the order make up to 10 mm. It can have two-sided protection and a multi-layer structure. It is used for finishing the facades of various buildings, protective shield constructions, partitions of rooms, bus stops. The more polycarbonate thickness, the stronger and more reliable the structures to be constructed.

Back to contents

Selecting the thickness of sheets of polycarbonate for canopies

Depending on the purpose of the structure, polycarbonate with the desired properties can be selected.

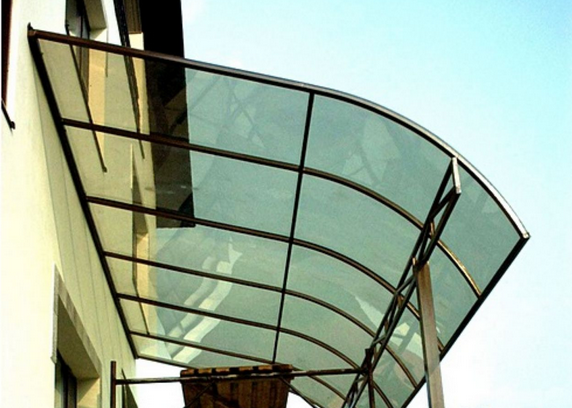

Canopy is an excellent attribute garden plot or production site. It can be made in the form of a flat surface or an arch with a transparent roof, open from the sides. Under it you can put a car, put a kitchen or a place for summer holidays. Its main part is the roof. Optimal material for the coating is cellular polycarbonate. Now produce several of its types, differing in thickness, which depends on the expected load.

The thickness of honeycomb polycarbonate for a canopy is selected depending on the purpose of the structure. For the construction of greenhouses can be used 4 mm. For awnings and canopies - 6-8 mm. If you need to build a canopy or canopy for a car, you can use 6 mm.

Cellular polycarbonate 4 mm thick is used for exhibition, advertising stands, gallery, arch structures.

Canopies of 8 mm are resistant to large snow, wind loads. They are designed for adverse weather conditions with large temperature changes.

Polycarbonate with a thickness of 10 or more mm is used under conditions of stronger external loads.

The most common for the canopy are 4 mm sheets. They are usually used for cover, located on or near the building, for billboards, cultural institutions.

Knowing all the above nuances, you will not have difficulties with the choice of material. If there are problems in the construction of a canopy, a visor, then specialists should be recruited. They will make the necessary calculations or order the manufacturing, especially if you need to take into account the curvature of the roof. The material depends on the material, which is important for saving financial costs. When building for each specific design, you need to choose the optimal thickness, taking into account its purpose. This approach maximally contributes to the correct execution of construction work and to avoid any errors or miscalculations in the design and installation of this type of product.

Today, structures made of polymer plastic, more commonly known as polycarbonate, do not surprise anyone, they use it instead of glass, film and other building materials. Almost everything is built from polycarbonate: gazebos, verandas, visors, garages, roofs and many other structures. Especially popular are canopies: light colored structures are an important attribute of suburban areas and the main detail of the design of advertising signs, bus stops, gas stations. And this is not accidental: polycarbonate cloths are very convenient to work with, they are light and have long operating time. Manufacturers produce polycarbonate panels of different thicknesses, colors and types, so without knowing all this information it is rather difficult to decide which polycarbonate to choose for the canopy.

Scope of application

Hinged structures, simply - sheds, are used in a variety of options and spheres. They can be seen near the city entrances or offices, near production and public buildings, many other objects. But the most popular are hinged structures in the home ownership of country houses and private plots. They are built over car parks, playgrounds, gardens, over yards, near houses and outbuildings - wherever people or things need to be protected from the effects of weather incidents: sun, rain, hail. At the same time, the reliability of the structure depends on the polycarbonate thickness for the canopy chosen.

Properties

The modern market of building materials offers polycarbonate of various variants. But regardless of the type of polycarbonate sheets, they all have really unique properties, which are very important when erecting various structures, including canopies. The main parameters, based on which polycarbonate canopies for canopies are chosen, belong:

- Resistant to weather factors, including temperature changes.

- High strength.

- Protection from ultraviolet radiation.

- A small weight of material.

- Protection against heat.

- Long operational periods, during which the material retains both its original appearance and strength characteristics.

- Low thermal conductivity.

- Economical.

- Large dimensions of polycarbonate canopies for the canopy, the choice of which also differs in the impressive color scheme.

There is this material almost perfect in all respects and disadvantages: sail, high cost of monolithic panels, insufficient resistance against mechanical influences. Knowing this, it's easy to avoid trouble. To the canopy did not fly away, you need to strengthen the frame well, if you choose the material of the appropriate thickness - he will not be afraid of hailstones or stones thrown from the street by boys who have been raschalilis. Of course, the cost of material can not be reduced, but high quality monolithic polycarbonate will fully pay off over the years. Proceeding from the above - the shortcomings of polycarbonate material as such can be called with great stretch.

The choice of polycarbonate cloths

Quality and thickness

Before starting the construction work, even at the planning stage, you need to decide - which polycarbonate to choose for the canopy for the thickness. This is a very important criterion on which the life of the structure depends. The purpose of the hinged structures is different, because of which, according to this parameter, the material should be selected separately for each specific case, considering the operating conditions and the dimensions of the structure. As has been repeatedly verified, cellular polycarbonate of minimum thickness to use for erecting various structures that will be used in the open air is not the most successful option.

For example, polycarbonate panels with a thickness of 6 mm are perfect for making small visors above a door or balcony. If the thickness of the sheets is 8-10 mm, they are quite suitable for making structures of even larger sizes. Polycarbonate with a thickness of more than 10 mm is already a fairly strong material, capable for a very long time to withstand the troubles of the weather and the environment.

With regard to quality, the polymer plastic can be made from different materials, so it is very important to know - which polycarbonate to use for the canopy.

On a note: To produce high-quality material, only primary raw materials are used, but polycarbonate, made from recycled plastic packaging, is already the second grade.

To define it is simple. Such material:

- when bending cracking or even can break - this is the main sign of low quality;

- not corresponding to this type of material - weight: one square meter of cellular polycarbonate 4 mm thick should weigh 800 grams, 6 mm - about 1, 3 kg, eight-millimeter - one and a half kilograms, and 10 mm thickness - 1.7 kg;

- the presence of various inclusions, uneven color, poor transparency are also signs of poor-quality material.

How to choose polycarbonate for a canopy - everyone decides for himself. You can, of course, save money, and buy panels of lower thickness or not so high quality - from recycled materials. But such an act is far from saving: for repairs or even a complete replacement of the paintings will have to incur much more money and time.

Colour

home technical specifications polycarbonate - just the color of the material, because this affects the transmission of light rays. If you choose beige, orange, red, then under the influence of the sun, the air under such a structure will warm up very quickly and stay there, especially at noon it will not be very comfortable. But the darker the color of polycarbonate sheets, the less heat and light they pass: dark sheets let about 30% of light, and light - about 80%.

In addition, beautiful colored polycarbonate panels can change the space. It is from the color of the sheets that the color of the space under them depends. For example, if a turquoise canopy is installed over the pool, the water in it will change - visually it will acquire the color of the sea. And if you know how to choose a polycarbonate for a canopy for a color solution, you can create real masterpieces.

Sheet structure

There are two kinds of polymer. In the vast majority for hinged structures honeycomb plastic plastic is used. It consists of two layers connected by a large number of ribs.

Good to know: Due to the special structure honeycomb form of polymer plastic has excellent thermal insulation properties, strength, plasticity.

For the manufacture of hinged structures, monolithic polycarbonate can also be used. Unlike a cellular analog it does not have voids inside it, which can be clogged with dust. In addition, it is easier to install, although it costs more than cellular polycarbonate.

Video about awnings for cars

Izyaslav asks the question:

Faced the problem of choosing polycarbonate. Tell me, what polycarbonate is better for a canopy over a gallery transition? And it will also be necessary to make the same visor over the porch so that everything is harmoniously decorated. Does the thickness of the material used depend on the area of the canopy? And whether to take into account weather conditions: the temperature range (especially low in winter) and the amount of precipitation?

The expert answers:

The polycarbonate canopy looks like a simple structure. In fact, it is. Having a frame, you can completely cope with the construction of such a lightweight construction. Polycarbonate lightweight roofs have a fairly long life. This structure will be sufficiently reliable if you choose the right material for construction and produce a quality installation. What criteria need to be taken into account to answer the question, which polycarbonate will be the best for the canopy?

First of all, it is necessary to take into account the climatic features of the region. In the area with snowy winter, canopies should be more durable, as in a country with a strong wind. At the same time, choosing roofing material for a polycarbonate canopy, you need to take into account its area, the architecture of the structure. It is these criteria that are fundamental for choice.

If the structure is a small visor with a relatively small bending radius, then a strong pressure of precipitation on the surface of the visor is excluded. Therefore, it is sufficient to use a polycarbonate sheet 4-6 mm thick. Such building material is better to use for protective roof-visors over small advertising constructions, porch.

Polycarbonate with a thickness of 6-8 mm can withstand snow cover up to 10-12 cm. But it is necessary to clean snow from roofs as needed. Polycarbonate of this thickness is used for greenhouses, arched galleries. For a country with a harsh climate, it is preferable to use a stronger material: a thin sheet under the influence of low temperatures, gusts of wind and pressure accumulated on the surface of atmospheric precipitation can deform (bend), up to the formation of cracks.

Polycarbonate with a thickness of more than 10 mm has high strength and anti-shock properties. For example, polycarbonate sheets with a thickness of 16 mm are used in industrial buildings - for the manufacture of lightweight roofs of large areas that can be subject to heavy loads. In winter, roofs made of such material must be periodically cleaned, so that the snow cover does not exceed 50 cm.

To exclude the stagnation of a large amount of water on the surface of the polycarbonate roof due to rainfall or snowmelt, the structure should be of the arched type (single-skinned or gable).

Colored transparent sheets of polycarbonate - a good solution for the construction of all kinds of canopies and canopies in the area near the cottage or a country house. It is a durable, durable and practical material, which, moreover, has high decorative qualities and is sold at a low price. Choose it on several parameters, and one of the most important among them is the color. What color polycarbonate to choose for a canopy, and what can it affect?

Polycarbonate color selection rules

One of the important properties of this material is the ability to partially transmit heat and sunlight. This is both a plus and a minus: under any canopy or canopy, you can have any plants, but it will not be a reliable protection against the summer heat. However, the translucency directly depends on the color, so you can choose the optimal solution.

On sale today you can find polycarbonate sheets of different shades, you can choose the appropriate option with the following regularities:

When choosing it is necessary to think not only about aesthetics, but also about comfort, as well as how the canopy will be combined with the overall design of the house and plot. Polycarbonate opens up a wide range of design possibilities, but it is better that such a structure is not too brightly allocated on the site, but would become its harmonious part. You can choose transparent, translucent and opaque sheets, polycarbonate can be installed on various types of skeletons.

Several advantageous options for the site

And yet, what color polycarbonate is better for a canopy or gazebo? You can not choose a single solution for each house, but you can use several design recommendations:

- For a pleasant coolness and partial shade, it is better to purchase frosted opaque sheets: they can be milky white or smoky-bronze. Such a canopy will effectively absorb light, while it will not visually block up space or make it gloomy.

- For a covered terrace or a gazebo, you can choose a translucent colored plastic of cool shades. It looks beautiful and creates a feeling of coolness, which will be especially noticeable on a hot midday. It is not necessary to choose bright colors, you can choose a calm, one-tone version.

- Completely transparent plastic is well suited only for greenhouses and greenhouses. If you choose it for a canopy or veranda, it will heat up very quickly, and underneath it will be unpleasant to be. Matt cellular polycarbonate will the best solution for all requirements.

Other polycarbonate selection options

The material is chosen not only in color. To the canopy was not only beautiful, but also durable, when choosing the following parameters should be taken into account:

- Thickness. The polycarbonate sheet for a canopy or canopy must be at least 6 mm thick, and thicker versions can be chosen.

- A type. Color polycarbonate can be not only cellular, but also monolithic. This material is most like glass, but it will be much stronger. It can be bent to certain limits, which allows you to create various curvilinear structures.

- Quality. Polymer producers are becoming more and more, but not all of them can offer really good and reliable products. When selecting, you must pay attention to the homogeneity of the material, in addition, when bending it should not crunch or crack.

- Manufacturer country. Chinese products are often not longevity, but it is quite cheap. The most expensive, but also the most reliable is the European and Korean plastic.

This directly affects the strength: too thin a sheet will simply break under the influence of snow and wind in winter, even with a pitched or arched roof. In addition, to increase the strength will have to put additional supports, which will increase costs.

Now the number of Russian manufacturers is growing, and the quality of polycarbonate is gradually improving, so domestic products can also be a good choice. Reviews of each manufacturer is easy to find online.

Correctly selected polycarbonate sheet can last up to 10 years, while the canopy will retain all its qualities. It is an easy and practical material that is easy to take care of, and which will perform its functions perfectly. Cellular polycarbonate has excellent thermal insulation and noise insulation properties, so it will be an excellent choice for verandas, arbors and enclosed terraces.

Polycarbonate is able to visually change and expand the space: the canopy will be light and elegant, this is a real decoration of the local territory. If it is harmonized in color and design with the house, it can be turned into a beautiful and useful space, increasing the house and allowing you to enjoy clean air.

You need to enable JavaScript or update the player!

Increasingly, polycarbonate canopies can be seen in the suburban areas. In order for their appearance to be the same as in pictures in glossy magazines and on the Internet, it is very important to choose the right materials. The most important thing is to pay attention to the main characteristics and parameters of polycarbonate, because it will be used as the main coating material.

Advantages and disadvantages of polycarbonate

Market building materials offers at the choice of the consumer a large number of different options polycarbonate sheets. All of them are characterized on the positive side, and their properties are very useful in the construction works, in particular the erection of awnings.

In order to understand what polycarbonate is better to choose for a canopy, let's consider the main parameters that should be paid close attention when choosing and buying of this material:

- Good resistance to adverse weather conditions, frequent temperature changes.

- Special strength.

- High protection against ultraviolet rays.

- A small weight of polycarbonate sheets.

- Resistance to burning.

- Duration of operation, in which the material completely retains all its properties and attractive appearance.

- Low heat conductivity.

- Affordable cost.

- A variety of colors of the material that allow you to transform any part.

Despite such an impressive list of positive qualities, polycarbonate has also negative aspects. For example, the sail, the fragility of sheets, the high price of monolithic panels. Knowing such nuances can always make the right choice and take security measures. To the canopy was strong and did not fly off, it is enough to strengthen the frame well enough. Sheets polycarbonate, thickness above the average, perfectly withstand rain, snow and even hail. As for the cost, it should always be remembered that good quality material can not be very cheap.

Having examined in more detail all the features of this material, it is worth noting that even negative aspects can always be turned into positive ones.

How to choose the right polycarbonate

Buying this material, it is necessary to pay special attention to its types. As a rule, the following types of polycarbonate are suitable for a canopy: monolithic and cellular. Each of them has its own positive and negative sides. Therefore, it is necessary to consider each specific situation separately.

Also buying polycarbonate is important to pay attention to other properties:

- thickness of the material;

- the color of the outer coating;

- the ability to transmit sunlight;

- plastic;

- fire safety.

Advice! Determining which polycarbonate is best for a canopy is important to draw special attention on the manufacturer. Before buying look at the reviews about manufacturers on the Internet, consult with friends.

Monolithic polycarbonate

In the construction market, this model is represented by sheets with a thickness of the order of 10 mm. For the installation of a canopy for suburban area More suitable are thin and plastic sheets with a thickness of 8 mm. If you select panels even thinner, then the design turns out to be unstable, very flexible and with very poor stiffness. Thick panels are expensive, so their use is not always economically feasible. They are well suited for awnings, which are designed to protect against the fall of heavy objects, such as icicles.

Attention ! Monolithic polycarbonate is not desirable to be used for structures with large spans, since many joints are formed during installation. This leads to the accumulation of a very large amount of debris, dust and dirt, and increases the likelihood of leaks.

This species has proved itself quite well on structures with curved crates and on single-pitched canopies, since flat surfaces made of this material are often deformed. This is due to the great flexibility and elasticity of this type of polycarbonate compared to other types of plastic.

The lifetime of monolithic polycarbonate is about 15 years, while many manufacturers give a guarantee for the entire period of use of the material. In appearance, this material is very similar to glass, but it is much stronger.

Cellular polycarbonate

This is a universal material for installation country house. In comparison with sheets of monolithic type, this option retains heat much better. Studies were carried out, where cellular polycarbonate and glass were compared in terms of the degree of thermal conductivity. The results were just amazing. Panels with a thickness of 8 mm, turned out to be better in terms of thermal insulation properties than a 20 mm glass packet. This property is determined by a special honeycomb structure, with a very large number of air voids, they are known to transfer heat very badly.

Unfortunately, the canopies made of cellular polycarbonate can not boast good throughput to light. Also, it does not differ and is particularly strong.

Determine the quality and thickness of the material

Before you start the construction work, even at the planning stage, you must decide what thickness polycarbonate is best used for the canopy. This is a very important point, which determines the service life of the entire structure.

Canopies can serve for various needs, so the thickness of the sheet should be chosen after it is known what exactly is planned to erect on the plot and for what purposes. For example, in practice it has been proven that cellular polycarbonate with the smallest sheet thickness is not very good to operate under the open sky.

Polycarbonate for canopies of a thickness of the order of 5-6 mm are very well suited for the installation of small visors over entrance door or balcony. Sheets of 10 mm thick are perfectly suitable for the construction of very large structures. Polycarbonate with a thickness of more than 11 mm is a very durable material that can be operated for a long time under the open sky, without worrying for its integrity.

The quality of the material directly depends on what it is made of. Therefore, when making a purchase it is important to know what exactly polycarbonate sheets are produced from. Determining the quality score is very simple:

- If the sheet is cracked or even broken when folded, the material is of very poor quality.

- The discrepancy between the weight of a leaf and its type. The meter of cellular polycarbonate 4 mm thick should weigh about 0.8 kg, a sheet 6 mm thick - 1.5 kg, and polycarbonate, whose thickness is 10 mm - 1.8 kg.

- The presence of various inclusions, irregular color or turbidity of the leaf also indicate a poor quality of the material.

Which polycarbonate is better to buy for a canopy, everyone decides for himself. You can save, and buy not very expensive, but, unfortunately, low-quality goods. But such a benefit is very doubtful. Frequent maintenance and short life leads to a quick replacement of the material with a new one. And this entails a new cash outlay.

How to choose the right color for the sheets

The main technical characteristic of this material is its color. It depends on it the indicator of the throughput of the sun's rays. Choosing beige, orange or red color, built canopy under the influence of sunlight very quickly warms up the air, and being under such a canopy in the summer in the heat will be extremely uncomfortable.

Attention ! It must always be remembered that the darker the polycarbonate color for the canopy, the less sunlight they let through, and the cooler it will be under it.

Before you understand what color polycarbonate is best to choose for canopies, pay attention to the ability of colored polycarbonate sheets to visually change the space. For example, if you erect a canopy from a turquoise color above the pool, the water will visually change into the color of the sea. Knowing such features, you can competently pick up the color solution of polycarbonate sheets and create not only beautiful, but also correct, comfortable in operation canopies.

Rules of work with polycarbonate

To work with this material is simple enough, but for this you must follow a few simple but important rules.

In order to mount a canopy on a site by yourself, you need to take into account the size of the panels used. The width of the standard honeycomb is 2 meters, the length is from 6 to 12 meters. The size of monolithic polycarbonate sheets used for the canopy is slightly smaller. Their width is 2 m, length is 3 m.

Sheets should be bent only by reproaching the canals. Longitudinal fold often leads to creases and cracks. Carefully hand over such a fold is possible only in an industrial shop.

Advice! If you plan to install a small arched canopy from polycarbonate, it is better to take the sheets thinner.

How to properly care for polycarbonate

Like any other material, polycarbonate needs to be cleaned and looked for the safety of its appearance. Dust, dirt and debris can accumulate on the surface of the canopy. To all this clear polycarbonate manufacturers recommend using a soft cloth or sponge, which is pre-wetted in soap solutions. It is strictly forbidden to use cleaning agents, which include ammonia, phenol ether or any other aggressive components. If the dirt goes badly to clean it is only a mild way, by no means using sharp objects.

Conclusion

Polycarbonate sheets are a very good alternative to metal or wood. It is a durable, reliable material that withstands any atmospheric loads and direct rays of sunlight. Polycarbonate sheets will never settle with fungi and mold. It is plastic and keeps heat well. A variety of color solutions will please any designer, who thus can realize any of his ideas.