You have reached the stage of building a house - the construction of a roof. We will tell you how to make a roof with your own hands, consider some projects and video instructions. Such roofs are popular in areas with expensive lumber. Also, a single-pitched roof is more suitable for strong winds.

The content of the article on how to make a roof with own hands

Single-pitched roof installation

Before the beginning installation works, find out the saddle roof device. Its main components are:

- rafter system;

- crate;

- hydro and steam insulation;

- heat insulation;

- roofing material.

Step 1 - the construction of the rafter system

To build a monogram roof with your own hands, you need to make a rafter system. The main stages of the implementation of these works are described below.

1. We begin with the installation of wooden supports for rafters

For work on insulation, polyurethane foam is suitable. The technology of thermal insulation of the roof with polyurethane foam is described in.

Step 4 - laying the roofing material

As a roofing material, slate or metal can be used.

Slate mounting

Slate is overlapped from the drain side. Each successive row of slate should overlap the previous one by 10-15 cm. The slate is clogged with special slate nails. This is done at the junction of 4 sheets (2 sheets at the bottom and top). When driving a nail, 4 sheets are attached. On the edges of the slate sheet, 2 nails are also driven from below and from above. On the features of working with the slate.

Laying of metal tile

Video about the errors of roof construction and roofing

Now you know how to build a single-deck roof. It remains to view the video - a single-pitched roof with your own hands, and you can proceed with the installation work.

Shed roof projects

On our site you can view or download projects of houses with a single-pitched roof and drawings of a single-pitched roof.

Projects of houses with a gable roof

When the house is almost ready to just put the roof, but here there is complexity, because many types of structures require a separate project. A single-pitched roof with its own hands is erected simply, but only if the person dealing with this issue knows what to do. For this, the features of such a structure and the materials suitable for it will be considered below, which will ensure the preservation of heat and protection from the weather.

Technology of making a single-pitched roof

The single-pitched roof attracts many in that it requires a minimum of building materials, and can also be built even with minimal skills in construction. This is the simplest type of roof, which is suitable for a residential building, and for economic construction.

Of course, the complex roof construction allows you to get a very attractive appearance of the building, but in this case it will take more building material, more time and, most importantly, more money for the whole project.

The ideal situation is when a single-pitched roof is created by its own hand according to the project that the specialist developed. In this case, it will only be necessary to comply with all the requirements listed there, but even then some difficulties may arise, some of which will be described in this article.

One-run construction, like many other types of roofs, is made using wood as the main building material. It is from this that the rafters, beams and elements of the crate and the rebound are obtained. For the role of roofing can be taken and slate, and metal, and Ondulin, and other materials.

Calculation of skate slope

Before you make a single-roof, you need to choose the right angle. It is determined by the material that will protect the roofing cake from rain, snow and wind. Obviously, tiles and slate hold snow and water differently than the metal profile, which also needs to be taken into account in the process of creating the roof. It should be remembered that the ability of a material to be quickly cleared of rain in this case is one of the key, since it determines the safety of the entire structure.

To neglect the analysis of the speed of the removal of precipitation is not worth it, because a large amount of snow, gathered after a heavy snowfall, will easily break the roof or greatly damage it.

Ruberoid or other roll material allows the use of the smallest angle of the roof, which can be only 5-10 degrees. Roofing, covered with slate, will require a 20-degree slope, and for tiles you need at least 25-35 degrees.

The smoothness of the surface is directly related to the minimum angle, which was clearly demonstrated by roll materials. In addition to the type of coverage, it is also necessary to take into account the terrain features, for example, if the roof of the building can be blown on all sides by the wind, skates can be sloped less. In the case when the building is surrounded by tall trees, you should make steeper slopes, because the snow will not be blown away by the wind.

Materials and equipment

When a single-pitched roof is erected with your own hands, you need to prepare the appropriate tools and materials. First of all, you will need:

- Wooden beams. These are the elements that will act as load-bearing structures. Their sizes can be from 12x12 cm to 15x15 cm.

- Boards. They will be required to perform the floor and the rough finish of the walls in loft, and must be stacked on top of the horizontal bar.

- Nails are slate and slate. In the event that a different type of coating is used, for example, Ondulin, then the fastener intended for this material must be used.

- Thermal insulation materials.

- Waterproofing membrane.

- Steam insulation.

- Nails for mounting timber and boards.

The tools will fit the same ones that are used for minor repairs and there is almost any house. This list includes a hammer, an ax, a hacksaw, a sharp knife, a construction stapler. The latter is useful in the installation of hydro and vapor insulation, because it is great for fixing films to rafters.

In the construction of the roof of a single-deck type, it is envisaged to use a crate and a grating, for which it is best to use a 5x5 cm beam.

The beams are installed in steps of 70..80 cm at the top of the wall. As a basis for them should be used seismopoias or mauerlat.

The first of these is a monolithic reinforced concrete structure, which is created along the upper perimeter of the walls. It repeats their outline and must necessarily be closed. It is used to increase the resistance of the structure to constant deforming loads caused by wind.

To create a seismogram, a formwork is mounted, the height of which should be slightly higher than the height of the future structure. The next stage is the reinforcement installation. When the installation of the roof by hand, it can do already several centimeters, than the wall itself, and the resulting gap is filled with expanded polystyrene.

Mauerlatt is a bar that fits around the perimeter outer wall and acts as the bottom reference point for rafters. The purpose of this element is to distribute the load, which is transmitted by the support points to the entire area of the upper edge of the wall.

The lower part of the saddle roof should be located on the leeward side.

Roof installation

After the installation of the beams is complete, the roof rafters are fastened on top of them, which will serve as a support for the top point of the roof. The number of rafters must exactly correspond to the number of joists. After the completion of this stage, it turns out a semblance of a right-angled triangle, the sides of which are formed by a beam and a vertical rafter. The final stage of installation of rafters is the installation of inclined beams, which are fixed by means of anchors to the concrete base or are attached to the mauerlat with nails.

For the convenience of the work on the rafters themselves, boards can be laid where the workers move during the construction of the roof, but then they are removed when the slate laying time comes.

Warming

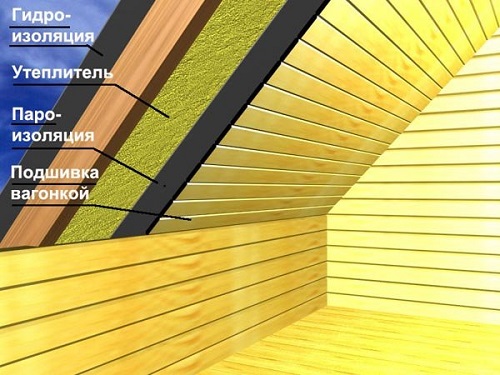

The construction of the roofing cake depends on the type of finish coat. In general, we are talking about a heater, which must be protected with a hydro and vapor barrier. The first is needed to protect the power structure from moisture and ensure a long service life. The second task of waterproofing is to protect the insulation from moisture from outside.

In the event that any moments remain unclear, then you can see how to create a single-roof with their own hands - the video is on our website. In it, all types of work are gradually shown, and also there is information about the materials that are best used for making the roofing.

Initially, the role of insulation was chosen for clay and cement-shaving slags, but they had a number of drawbacks. These materials did not adequately withstand the effects of water and could not withstand required amount heat, giving it to the atmosphere. Today, complex materials are used, for example, URSA. A special insulating mat includes:

- plates of heat-insulating material;

- flat glass fiber blocks;

- basalt heat insulation mats.

The main advantages of such materials include relatively low cost, efficiency and ease of operation.

Before you mount the insulation, you need to create a waterproofing. It is performed using a special material laid on top of the rafters. This is done if the thickness of the thermal insulation is less than the height of the rafter. In the case where the heat-insulating material is equal in thickness to the height of the rafter, the film is placed on the upper planes of the bars intended to increase the height of the rafters. The waterproofing material is mounted across the ramps, and the overlap must be 100 mm. Between the waterproofing material and the roof you need to leave at least 50 mm of clearance, for which pre-prepared 50x50 bars are suitable.

After the mats of the thermal insulation material are unpacked, it is necessary to wait until it resumes its dimensions. This will take no more than 15-20 minutes, and you can speed up the process by shaking the heater.

If you know in advance what the width of the insulation will be used, then this should be taken into account when designing the project, since 1.2 m mats can be laid in 2 layers with a distance of 0.6 m between rafters, and in other cases they will have to be cut.

After the heater has taken its original shape, it is cut and placed between the rafters in accordance with the project, which carries out the construction of a single-pitched roof with their own hands. In this case, it is worth noting that the installation of the material is done at a distance, and its width should be greater than the distance between adjacent rafters by 30 mm. If the mats were cut not along the length of the ramp, in order to ensure reliable isolation of the horizontal sections, they should overlap by 20-30 cm. A certain gap should be observed between the heater and the waterproofing film, for the preservation of which it is possible to use conductors made of bars.

The final stage of installation of thermal insulation material is the vapor barrier device, which is located in the lower plane of the rafter legs and fixed with galvanized nails having a flat head or staples of a construction stapler. The vapor barrier film is laid with an overlap of 10 cm, and to ensure tightness, the webs are joined together by special adhesive tapes.

Creating a roofing

The lining is designed to hold the finish coat and it rests on the elements of the counterbrush, nailed to the rafters. Usually, for these purposes, 50 x 50 mm bars are used, and the distance between them depends on the material selected and the technology used.

The lining for slate should not be made from gnarled boards, as it can not withstand the snow load. Raw lumber is also better not to use, because as the boards dry up, the fastening will loosen and begin to loosen, which will weaken and then destroy the entire roof.

Most simple version is slate, so we will consider it exactly. For the installation of corrugated sheets, a transverse lath required in such a way that there are 4 bars under the slate sheet. Those. the first of them is the local lower overlap, then 2 elements of the crate, which hold the central part of the slate, and the 4th bar, which is needed as a support for the upper part of the sheet. When using sheets with a length of 175 cm, the distance between the horizontal bars of the crate is 175/4 = 44 (cm).

In the event that it is intended to use other material, the crate will also need its own. For example, for direct slate a continuous crate is needed. Under soft tiles or roll roofing Use a crate of plywood sheets, etc.

The technology for creating the roofing depends on the material chosen for the roofing, so it must be strictly observed, otherwise expensive roof repairs can be made, with the replacement of all elements of the roofing cake.

Installation of the finish coat

Since this article looks at how to create saddle roof at home with their own hands, in matters of installing slate, it does not make sense to delve deeply. Below, only general points will be considered, which can be refined in the material devoted to working with the slate. It is posted on our website as a separate article.

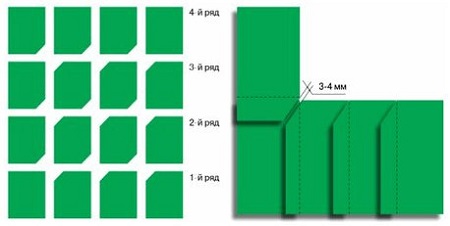

Mounting sheets is best to start on the leeward side. The top layers are laid with an overlap on the bottom. The most common is the following installation:

- the first sheet is placed next to the pediment overhang;

- then two more are mounted in the first row;

- after that two sheets are stacked in the second row, and in the first one, etc.

During the work, it is necessary to ensure that the vertical overlap is within 12..20 cm, and the horizontal overlap is one wave. In this case, the sheets are stacked so that the sides of the elements of the top layer coincide with the sides of the lower members. It is also worth noting that the corners of the sheets are cut so that there is no distortion in the places where four sheets intersect.

In addition to ridge and cornice, all the others are trimmed in such a way that the size of the cut off section is equal to the amount of overlap, increased by 0.5 mm, this allows to join adjacent sheets with a gap of 2-3 mm.

Angles of slate can not be broken. This will lead to a reduction in strength and the appearance of cracks. Even if it is impossible to see them visually, then sooner or later they will appear, which will lead to accelerated deterioration of the roof, which means that it will require expensive repairs.

Slice the slate with a hacksaw or with a circular saw, and the resulting slices are painted over.

Prevention of damage to a saddle roof

One of the main problems of such structures is the excessive amount of precipitation that has fallen out in the winter. It is the mass of snow that negatively affects the condition of the roof, so you need to take measures to solve this problem. One of the most dangerous are thaw snowfalls, which can cause complications due to the fact that snow adheres to the roof.

In order to avoid complications due to excessive snow, it is necessary to think about how its operation will be carried out, and also to assess the location of the exits to the roof and windows from this point of view even at the stage of developing the appearance of the roof.

Inspect the roof, too, must be carried out annually, and special attention You need to pay attention to the condition of the roof and trusses. Sometimes there may be a weakening of the wood due to damage to rot, and there may be problems due to rodents.

As part of the annual inspection, it will not hurt to remove the various debris accumulated between the slate waves, since it has a negative impact on the state of the roofing. During the rain, a large amount of water accumulates here, which gradually destroys the slate, and snow will be faster to collect.

Brief summaries, we can say that in this article was given a fairly detailed answer to the question "how to make a saddle roof?". We examined most of the important points and even gave an example of a suitable way of laying the finish coat. Of course, slate is not the only suitable option, but you can find out about other types of coatings on our website by reading an article dedicated to each kind of material.

One-pitched roof is an original and at the same time affordable solution for almost any building.

Advantages and disadvantages

One-pitch roof is a creative solution for a residential building.

The advantages of such designs are as follows:

• Ease of design.

• Cost (saving 30 - 35%).

• Saving of material (consumption is 2 times lower, in comparison with gable versions).

• Ease of installation.

• Resistant to strong winds.

Tip: for regions with protracted winds, single-pitched roofs are the best option.

• Quick installation.

• Availability of repair.

A few spoons of tar in this barrel are present:

• Inefficient use of the attic. Attic with such a roof can not be built.

• The drain is directed in one direction. This requires the creation of a solid drainage system.

• The structure is less attractive.

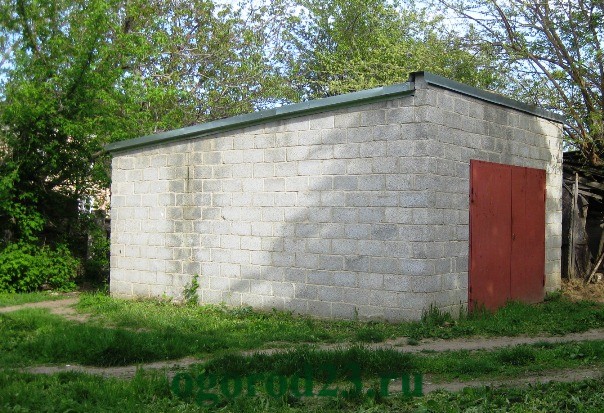

Because of these factors, single-pitched roofs for overall structures are rarely used (except for combined structures). Most often they are used for outbuildings, garages, baths and outbuildings.

Preliminary procedures

The roof is made of different materials (galvanizing, siding, ruberoid, etc.). We will consider a variant with a slate.

Calculations

Before work starts, calculations are required. First of all, you must determine the orientation relative to the prevailing wind. It must pass from the bottom up, as if trying to climb. In this case, the pressure on the structure will be minimal, which will ensure its durability. If it is a question of a combined roof, then it will be the one-stage one that sets the tone for the construction. With its location it is necessary to decide in the first place.

When using slate, the slope should be 20-25 degrees (roofing material - 10, tile 30-35). When it comes to small buildings (for example,) many prefer to do calculations "by eye", due to the small number of materials. For those who are loyal to the Tsarina of Sciences, we present the formulas:

1. Lf = Lst x tgA, where Lf is the height of the pediment, Lst is the length of the wall, and A is the angle of inclination.

2. Lp = Lph / sinA, where Lstr is the length of the rafters.

Tip: To find the sine and tangent, use the Bradys table.

Example: the length of the wall is 5 meters, and the angle A is 25 degrees. The length of the pediment is 5 x tg25 ° = 2.35 (m). L rafters will be: 2.35 / sin25 ° = 5.6 (m).

Based on the values obtained, we do material calculations, not forgetting to add 10% (for pruning and marriage).

Preparation of the toolkit

Laser level - the guarantor of high accuracy

To achieve this goal you need the following:

• Board (not edging).

• Wooden beams.

• Slate.

• Nails.

• Waterproofing material.

• Knife.

• Level.

• Building stapler.

• A hammer.

• Saw.

The main front of the work

From the theory immediately go to practice. The whole process is divided into stages.

Installation of beams

Schematic structure of the structure

First of all, we create a supporting structure of beams. It will hold all the other elements. The work is done in the following order:

• We fasten the beams to the Mauerlats (a bar located on top along the perimeter of the outer wall). This technique is used if there is no reinforcing belt on the walls or it is too uneven.

• Mauerlats are placed horizontally over the waterproofing. We fix them with anchors and wire.

• The size of the beams and the pitch depends on the length of the span and the estimated weight of the structure. Most often adhere to the range of 75-95 cm.

• On top of the beams lay the flooring of the boards (for walking on the work site). Alternative solution - prefabricated scaffolding. They are more stable and reliable than the design of the boards.

• On the fixed beams, we mount vertical racks. They need to be set strictly on the level and securely fastened to each beam. Vertically fix the racks with the help of braces.

• We put the top run on top of the supports. Due to this design the rafters will hold, so it needs to be placed horizontally.

Rafters

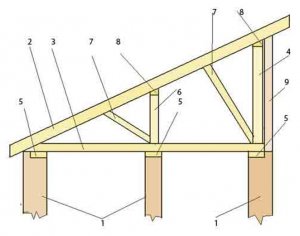

1 - walls; 2 - rafterleg; 3 - beam; 4 - support; 5 - Mauerlat; 6 - one more support; 7 - brace; 8 - run; 9 - finish.

Now we mount additional elements - rafters:

• From above, they are fixed to the binding with nails (20 cm) and construction staples (angle of driving is 45 degrees). From the bottom of the rafters are attached in this way. As a result, you must get a set of straight triangles.

• The rafters can be fastened directly to the vertical support, but then it will be necessary to put them on the level with the jeweler's precision. This can only be done by skilled craftsmen. The upper bandage gives the strength of the structure, so it is better not to abandon its use.

• If the rafters are very long, you will have to create intermediate supports. They are fixed on load-bearing walls. In extreme situations (when the length of the span is more than 4 m), you can create support stops.

Rims

With the rafters figured out. Now our task is to create a crate. It is made of boards 3x4 cm (from the point of view of economy it is better to use not edging) or bars 5 x 5 cm. These elements are nailed perpendicularly to the created rafters.

The step of the battens is approximately the same as the beams. To give durability to wood, it is recommended to cover it (bars, beams and boards) with an antiseptic.

A few words about waterproofing

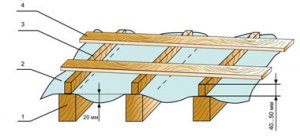

It is recommended to use a waterproofing film to protect the premises from moisture. It is sold in the form of rolls. This is done before installing the crate.

1 - rafters; 2 - a film; 3 - slats; 4 - crate.

Mount the film to the rafters using a stapler, starting from the bottom. Finally, it is fixed with the help of longitudinal rails, laid along the rafters. The lining is installed directly on the slats, which creates a natural ventilation in the room. Waterproofing is mandatory if the slope is small (less than 20 degrees).

Completion - laying the roof

In the end, it remains to fix the roofing material (in our case, slate). In each sheet there are prepared holes (in them nails are hammered). Slate fits within 15-20 cm.

No construction is complete without a roof, and, depending on the type of construction of the structure, a complex separate roofing project is being done.

Make saddle roof with their own hands is easy, if you know all the subtleties and stages of construction. For this, it is necessary to familiarize yourself with the features of this design, necessary materialsto make the roof warm and protect the house from weather phenomena.

The roof with one slope is considered to be the simplest in construction technology. For its construction requires a small area with a slope of not more than 25 degrees.

True, such a roof has some drawbacks, it can not be made a loft and attic, and the view is very simple. But you can make it attractive with the help of corrugated board.

If you need to make an inexpensive roof, then you can use slate, it is resistant to frost and moisture, durable and almost not exposed to damage by ultraviolet. In the article we consider step-by-step instructions montage of a saddle roof.

In order to make a saddle roof you need to purchase:

- Beams

- Rafters

- Curb

- Overlapping

As a finishing material, use tile or slate, ondulin or metal tile.

Kinds of single-pitched roofs

Depending on the design, the angle of inclination, the width of the span and the type of roofing, the single-pitched roofs are divided into several types:

Depending on the design, the angle of inclination, the width of the span and the type of roofing, the single-pitched roofs are divided into several types:

- When rafters have a support on the walls at different angles;

- When rafters are made as a one-sided triangular truss, with a support at one level;

- Mansard shed roof.

To make the roof of the first option Need less wood, but at the same time one of the bearing walls should be higher than the other. But for the second option, the walls should be the same level, but more wood will be needed, and the work will be more difficult. When choosing a roof option for construction, it is necessary to consider the width of the span, the number of materials and the conditions of construction.

Single-pitched roofs differ in the number of supports for rafters, they can be made without intermediate or with several intermediate ones. Depending on the length of the rafters and their slope, the need for additional support is determined. Rafters can be laid on the Mauerlat or on the joists.

How to prepare for the construction of the roof?

First you need to make the drawings, the scheme and calculate the dimensions and angles of inclination, after which you can calculate the right material. From the slope of the roof will depend on the amount of material, because for a small slope it will take less than for a large one.

But if you make a slight slope, the water will not flow so well and at the joints of the sheets increases the likelihood of leakage, and the load on the rafters will increase.

- If you use corrugated board, the angle of inclination should not be less than 20 degrees. Otherwise, snow can bend the roof. It will also be necessary to make a waterproofing, especially if the ramp has a length of more than 5 meters.

- If the roof is made of metal or slate, it is better to make an angle of inclination from 25 to 40 degrees. If this is not possible, then it will be necessary to make a good waterproofing.

What are the options for a single-pitched roof project?

There are several variants of projects for saddle roofs:

- At home with a small attic, who have a direct ceiling on the top floor. With such construction will be improved thermal insulation. Due to the increase in the height of the attic it will be easier to maintain the structure.

- If the house does not have an attic, the roof will serve as an additional and ceiling cover. But then the ceiling on the top floor will be uneven. The ceiling will have the same angle as the slope of the ramp.

Often small single-storey houses make a rectangular shape, in such a situation, to calculate the roof, it is necessary to calculate the height difference on opposite walls. This design is the simplest, and suitable for country houses and villas. It is desirable that the windows were small, and the design of the house is made restrained and inexpensive.

If the house is large and has several floors, then the roof is broken, you can make an attic, as well as a garage. If the house with an attic, then the ceiling will be flat, and when without it, the ceiling is made with a slope. Very good look at home where different decoration Materials, with different colors and textures.

What will it take to mount a saddle roof?

- Wood for rafters, supports and beams measuring 7 - 15/20 cm;

- Board 4 cm, or a beam of 5 cm;

- Cutting board 2,5 - 3 cm - will be needed for sewing the ends and side parts;

- Different in length nails;

- Special screws for roofing;

- A hammer;

- Ax;

- Hacksaw;

- Chainsaw;

- Screwdriver;

- Stapler;

- Material for the roof.

Calculate how many bars you need to build on the rafters, as well as the weight of the roof and the distance between the rafters. It is recommended to make a gap between the rafters about 60 - 100 centimeters. The material for the crate is calculated depending on the area of the roof itself, as well as on what type of roofing material you have chosen.

The main stages of work

Trussing system installation

- For the construction of a single-pitched roof it is necessary to make a rafter system. It is best to use coniferous wood. Logs must be well dried and treated with antiseptic, do not put the composition to protect from moisture and from fire.

- Mauerlat is laid along the bearing wall. This stage is very important, it will ensure the reliability of the design. Also, you can tie a wall-welded wire, or attach it with anchor bolts.

- Further into the Mauerlat at the ends of the beams You need to cut the nests with a double tooth, and they are fastened with special staples.

- The place where the beam is to be closed ruberoid in two layers, this is done for waterproofing.

Rims

- Skeleton lathing is made from planks, beams and poles. The wood is also treated with special compounds for protection.

- That the lath was durable It is necessary to sew boards at a distance of up to 1 meter perpendicular to the rafters.

- Bars and boards with a distance of up to 15 centimeters They fix on the received skeleton taking into account the slope.

- Short parts for the flooring of the lathing it is necessary to alternate in staggered order.

- When making a crate, it is necessary to take into account in which way the roofing material will be fastened.

Waterproofing and vapor barrier

- To the crate, it is necessary to attach a vapor barrier material, use a construction stapler or small nails, but with a wide cap. Depending on what structure the roof is made on, it is possible to produce a roofing roof.

- Further with the help of waterproofing all the joints are covered.

Installation of roofing

Mount sheets are required from the leeward side. It is imperative that the upper layers lie in an overlap on the lower ones.

Mount sheets are required from the leeward side. It is imperative that the upper layers lie in an overlap on the lower ones.

- Lay the first sheet next to the pediment overhang;

- In the first row, two more sheets must be mounted;

- Next, you can lay two leaves of the second row and another one of the first.

It is necessary to make sure that the vertical overlap is about 15 to 20 centimeters, and the horizontal overlap is made on one wave. That there were no skews in a place where four sheets coincide, edges should be cut off. An exception is the installation of ridge and cornice sheets.

In no case should you break off the corners of the slate, otherwise cracks will appear on it.

How to establish ebb and protect the house from the wind?

The last stage of montage of a single-pitched roof is the installation of tin.

To do this you need:

- To begin with, it is necessary to nail the wind board onto the logs that protrude from above and below.

- To set ebb tides you need to choose a place for them and nail them with nails. This work is very simple and does not take much time.

How to make a roof for a bath?

There is a wide variety of materials for creating a single-deck roof for a bath:

- The material should be durable, moisture resistant, and also be combined with the appearance of the building.

- Often for baths use metal roofing, seam roof, corrugated board, roofing felt or slate.

- If the sauna is wooden, then it is worth taking care of good steam and waterproofing, and the roof will need to be insulated.

Saddle roof for garage

Roof for construction or verandah, barn

If a verandah, a gazebo or a barn, a summer cottage should be used in the warm season, then it is enough to make a saddle roof. But for a loft it's better to make a roof of a corner kind.

To make a roof for a verandah is absolutely not difficult:

- It is necessary to determine the angle of inclination.

- Next it will be necessary to make a wooden frame.

- Install the rafters.

- Cover the structure of the roof.

Since such buildings are not intended for living, the material for the roof can be purchased is not very expensive, the slate used to be very popular, but today the market offers a wide variety of alternative types of coatings.

It can be easy and affordable materials, such as metal, and it can be put in one layer without joints.

- If the structure will be used in the winter, it is recommended that the roof be insulated. For this, the insulation is laid between the beams on the auxiliary crate, after which the rafters must be gypsum plasterboard or plywood.

Advantages and disadvantages of a saddle roof

In a single-pitched roof, as other species have their pros and cons, it is necessary to consider them before determining the type of roof.

Benefits:

- The roof is affordable

- With its help, the structure is reliably protected from strong gusts of wind, which is suitable for windy regions

- To build it is quite simple

- With a slight slope, the roof can be used as a resting place or as a greenhouse

Disadvantages:

- Due to the small angle of the roof, a large amount of snow accumulates on the roof, this can cause the roof to be pinched

- To make an attic or loft insufficient space

- It is impossible without complete difficulty to make a complete thermal insulation

How to insulate a house with a gable roof?

Previously, cement-chip slags or clay-concrete were used to insulate the house, but such materials do not provide good thermal insulation, and they deteriorate from snow and rain.

To date, construction companies have begun to use more popular materials, such as URSA. It includes a heat insulation plate, fiberglass blocks or glass wool, basalt mats.

If you make insulation using URSA, then the cost of money will be minimal, and installation is very easy.

Operating procedure:

- Under the steam and waterproofing the first coat. This will ensure good ventilation and dryness.

- Under the slope is a vapor barrier, especially if the ceiling is made of plasterboard or it will be tension.

- To the roof was a dwelling,it is worth using foam insulation for insulation, it will protect the room from moisture from the outside and from the middle.

- Where the overlap is horizontal, thermal insulation should be with a minimum density.

How to do preventive maintenance for a saddle roof?

Since in the winter season a lot of precipitation falls on such a roof, it is necessary to look after the roof. For the roof, the most dangerous is thaw snowfalls, since snow with heavy weight simply sticks to it.

Every year the roof needs to be inspected, especially in the case of the rafter. Rodents can damage it, and wood can also rot. Annually remove from the roof debris, which accumulates on the waves of slate.

Despite its simple, uncomplicated design, single-deck roofs are in demand, they are rational, especially for suburban housing construction. Roofs with a single ramp are also used in large quantities to equip garages, house buildings, farm buildings. On how to build a single-pitched roof with your own hands step by step, you'll find out below.

The multi-skinned versions of the roofs are complex in design, and the one-run roof is quite accessible to erection with your own hands, since it is, in fact, a rectangle that is located in the same plane, without bends. On one-sided, by the way, you will have much less building materials than any other, it will be more resistant to seasonal manifestations (snow, wind, rain).

Construction of a gable roofAdvantages of a saddle roof:

- light weight;

- comparatively acceptable final cost;

- affordable, simple installation process;

- the possibility of using various building materials (roofing, rafters);

- affordable accommodation drainage system, chimneys.

Chicken coop with a walk for chickens under a gable roof

Chicken coop with a walk for chickens under a gable roof

Despite its simplicity, a single-pitched roof can be very creatively played in design solutions. The angle of its bias directly depends on the climatic characteristics of the region where you live. If you are accustomed to snowy winters, then the degree of inclination should be greater (to make the snow slip better), if your house is located in a windy place, then the slope should be made smaller. For the same reasons, the slope of the gable roof should be directed to the opposite side from the facade, so that the precipitation "leave" behind the house.

The roof is one-run, built by oneself, step by step, it is ventilated and unventilated type. The first option is applied to residential buildings, the gradient varies from 8 to 25 degrees. In such cases, air exchange is ensured by an insulating layer and special holes located on the sides of the roof.

Extension - garage and shed with a roofed roof

Extension - garage and shed with a roofed roof

Non-vented option is often installed in garages, sheds, extensions to the house, the angle of inclination is mostly small - 3-6 degrees.

House with a saddle roof - the choice of roofing material

Calculation of the schematic drawing of the future home begins with the determination of the required angle of inclination and suitable roof covering material. Most often for such single-sided structures used corrugated board, metal profile, ruberoid, tile, slate, metal or ondulin. Soft tile or roofing coating is optimal for very small slopes - from 5 to 10 degrees. Slate with profiled sheeting are more suitable for "medium" slope - from 20 to 30 degrees. For metal tiles, a slope of at least 35 degrees is required.

The choice of roofing material is determined by its ability to interact with atmospheric precipitation and to remove them from the surface in a timely manner. For example, with slate, corrugated board, shingles, snow comes off much easier.

How to make a saddle roof?

To build your own hands step-by-step roofs of the same type, you will need a standard set of construction tools, the necessary building materials. Materials made of wood (lumber) must be of proper quality with a maximum humidity of 22%. All wooden materials are recommended to be pretreated with antiseptic agents (for example, with means from the DrevoTex series).

In addition to all you must have in stock fasteners: bolts, struts, struts.

Rigel is a horizontal piece that acts as a support for other supporting structures, it distributes the load of the rafters to other beams.

Spacers - a variety of supports, which are located in the spans, provide greater stability of the entire structure.

The struts are the beams that act as supports for the rafter system.

Shed roof extension to the house

Shed roof extension to the house

One-pitched roof, photo:

You should have:

- the wooden beam is 100-150 cm in diameter;

- laying boards (thickness at least 5 cm);

- rafters nails;

- heat-insulating materials;

- waterproofing materials;

- building scotch;

- tools (ax, saw, hammer, construction knife, plumb, screwdriver, tape measure, construction stapler, level).

The rafters of a saddle roof will depend entirely on the size of the future house and building material, from which the walls were erected. The rafters are always installed on the Mauerlat, if the construction is small and the length of the span does not exceed 4.5 meters, then the scheme of the gable roof system will be extremely simple. It will consist of a basic mauerlat bar and a rafter. If larger sizes of the structure are assumed, and the length of the span is more than 6 meters, then installation of reinforcing leg under the feet is simply necessary.

Scheme of roof rafter system

Scheme of roof rafter system

The rafters must be installed in accordance with the building rules, so that after a few years of operation the consequences do not appear. Do not forget about the safety rules - install on the rafters reliable, strong temporary boards, by which you will move during the construction process.

Setting roof rafters

Setting roof rafters

The workflow with its own hands provides for the following stages:

- Laying of cross rafters - they are fastened to the Mauerlat (this is the basis for what the entire rest of the rafter system is), the distance between the rafters is about 60-80 cm. Here you will need large nails (or anchors).

- The rafters are fastened with a sheath (it is made of wooden slats 50 to 50 cm), it provides rigidity, the roofing material is laid directly on it. The clipping is placed at right angles.

- With the help of a construction stapler, a waterproofing material is attached to the lath (a conventional polyethylene film is suitable for these purposes). Fastening is made without stretching, but with an overlap from the bottom up.

- There should be a turn of thermal insulation (for example: mineral wool, fiberglass, balsamic mats).

- Laying roofing material according to its individual characteristics.

Single-pitched roof with own hands

Let's consider step by step the whole construction process:

Qualitatively laid, secured with their own hands rafters do not bend under the weight of 70-100 kg, if this fact was found during the inspection, then it is necessary to strengthen the frame.

The technology of laying the layers of "pie" can vary due to certain circumstances, to have some additions. Sometimes, for greater reliability, the waterproofing layer is re-laid over the insulation. It will not be worse from this, but in all cases, special attention should be given to fastening.

To nail the film to the wooden elements of the construction is best with the help of nails with a flat hat or a construction stapler, the step frequency should be 15-20 cm.

One of the most important moments is the fixing of the edges of the waterproofing material. It is planted under the overhang of the roof, the rest of the segment should be at least 20 cm, then pummel from below with nails or, again, pass a stapler.

It is best to take a wooden rod and punch it with the appropriate nails (with a pitch of 10-15 cm) - this is the so-called "folk" method for building a saddle roof. Thus, you will be sure that air flows will not penetrate under the waterproofing film, will not cause large-scale damage in the presence of strong winds.

Errors of fixing the edges of the gable roof of the garage

Errors of fixing the edges of the gable roof of the garage

In the photo above, the edges (overhang) of the roof were unreliable. In strong wind, the metal profile sheet together with the waterproofing film, like a light rag, was easily thrown aside.

One-pitched roof - extension to the house

Garage, as an annex, under a gable roof

Garage, as an annex, under a gable roof

For garages, sheds, baths, arbors the most convenient is this type of roof. The construction of a single-pitched roof provides a number of advantages for the so-called auxiliary structures.

Fastening of the rafter frame of a saddle roof to the wall of the house

Fastening of the rafter frame of a saddle roof to the wall of the house

If you look at the annex step by step, it becomes clear that its roof is adjacent to the wall of the residential building. Thus, its truss system is equipped separately from the house, the lower ends of the rafters are located on the facade wall of the extension, but the upper ones are attached to the wall of the building. It is very important to ensure a competent connection of the rafter frame of the extension and the main wall of the house. Too rigid fastenings too to use it is undesirable, therefore as the speed of shrinkage of the house and an attached building can be different. Because of this difference, then, cracks in the walls may form.

In this case, it will be most convenient to lay the beams on a timber frame, which is adjacent to the wall of the house (attached to the wall), and the place (seam) between the timber and the wall is filled with polyurethane sealant. To lay the roofing material with your own hands on the roof of the extension it is necessary with overlapping, and also to get in the place of the joint under the cover of the house. This is necessary in order that later atmospheric precipitation does not leak through the junction. Usually a similar roofing material is used on the roof of the house and the extension - for aesthetic reasons.

If you decide to build a shed with a gable roof, the construction of the roofing system with your own hands will not significantly differ from the above-described step-by-step method of erection.

It happens that sheds are erected from a bar, in such cases the top of the log cabin acts as a Mauerlata. In other respects, there are significant differences in rafters shed roofs of different buildings are not available.

The roof for a one-run garage is made using a similar method.  If the walls of the garage are built of bricks, then the edges of the beams, the rafters are embedded in niches equipped for this. They are pre-made in the walls and discussed in the design stages of the building. It is recommended to wrap wooden fragments with a waterproofing coating before entering into these niches. In this case, the interval of the rafters is 60-70 cm. Facade wall garage - a high wall, from which there is a ramp down to the rear of the building, the entrance gate is located in it. The roof should protrude 30-40 cm from the wall, form a small overhang.

If the walls of the garage are built of bricks, then the edges of the beams, the rafters are embedded in niches equipped for this. They are pre-made in the walls and discussed in the design stages of the building. It is recommended to wrap wooden fragments with a waterproofing coating before entering into these niches. In this case, the interval of the rafters is 60-70 cm. Facade wall garage - a high wall, from which there is a ramp down to the rear of the building, the entrance gate is located in it. The roof should protrude 30-40 cm from the wall, form a small overhang.

Taking into account the above information, it becomes clear that such a roofing variant is practical, functional, structurally simple. One-pitched roof, with its own hands step-by-step arranged, can withstand powerful wind, snow loads. Such a roof will be warm, thanks to a small area to penetrate the air. If you have done everything right, it will surely serve you for more than a decade.