The choice of roofing materials depends on the weather conditions of this or that area, the quality of the surface, its overlap, the angle of the roof and many other factors. Ruberoid and tolite are the simplest and most affordable roofing materials. Their advantage is that roll materials provide reliable insulation from moisture, because they are stacked in several layers. Although the roofs of roll materials are afraid of fire, but they are very economical and practical. Elasticity of materials allows them to cover any surface, as it takes the form of a roof. Additional care after the application of materials do not require, or roofing will serve a long time.

The choice of roofing materials depends on the weather conditions of the area in which the installation will be carried out.

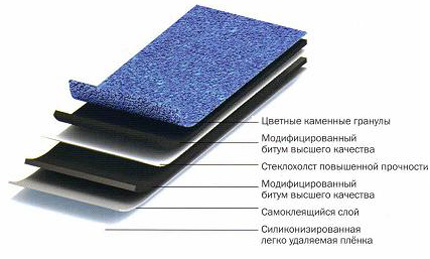

This generation of roll materials is called Eurorubiroid. It includes bitumen, SBS and APP modifiers and a base (fiberglass, fiberglass or polyester). The technology of production is borrowed in Italy. Thanks to the modifiers, the Euroruberoid can withstand temperature jumps in the range from + 130 ° С to -25 ° С, and some of its types can be stacked even in winter. The use of modern types of base allows avoiding common problems when laying material: tears, decay, inelasticity. Euroruberoid can be used for the device of any type of roof. For the construction of the future roof, covered with euroruberoid, the composition of the finished mass is added with mineral crumb - shale or granulate, which also serves as a protective layer against the intense influence of the sun.

Advantages of euroruberoid on the face: its use for the construction of roofs is possible in any climatic zones, the composition of the material does not allow moisture to penetrate, the plasticity of the finished rolls facilitates rapid laying. The service life is up to thirty years. There is only one drawback - when laying you need to use a gas burner of good power.

Laying an ordinary roofing paper

Laying roofing material makes it possible to avoid such frequent problems as: breaks, rotting, inelasticity.

To qualitatively lay the roofing materials, you first need to prepare the surface for their installation. The basic requirement for all surfaces is the absence of any kind of deformation or dust. Look at the area for the presence of protruding pebbles, reinforcement and other irregularities, and remove them. It is possible to cut or coat with a thin layer of concrete, the main purpose is an absolutely even roof. If the roof with a slope, the crate must be solid, it is additionally necessary to cover it with construction paper in 2-3 layers. If this is not possible, then an incomplete crate must be filled with an asbestos sheet 5 mm thick. The result will be the same, although the costs in the latter case will be much higher.

The stacking technology is quite simple. The usual roll roofing material is fixed with the help of melted mastic: bitumen or primer. Apply the melted mass only to a clean and leveled surface! Of course, you can use cold bitumen, melting it in place, but this process takes time, so it's better to use the finished mass.

Lay out the materials necessary taking into account the angle of the slope of the roof. If the slope is more than 15 °, then the planking must be perpendicular, if less than 15 °, then parallel to the roof ridge. Rolls should be unwound, measure the necessary length of the tape and cut off. Best of all, immediately cut a certain number of ribbons for styling, so that they can only be taken and fixed on the working area. Put the finished materials aside, folding them into rolls, and get to work.

Lay the bottom layer of ruberoid stands from the bottom up. The melted mass of bitumen is poured onto the roof and uniformly, at least 2 mm thick, distributed over the entire surface with a roller or a squeegee. On it lay the cut off tape of a ruberoid and press. The next tape is superimposed on the previous one with an incision of not less than 10 cm. The roof horn is additionally covered with a tape of roofing material with an incision of not less than 50 cm on each side. Each subsequent layer of roofing material, and they need two or three, are pressed tight. After the completion of the roofing system, you can additionally fill the bituminous mass with complex sections of the roof: bends, joints, places around the pipes.

Technology of roof construction from euroruberoid

The laying of the eurorebearoid and all other types of second, third and fourth categories of roll materials is carried out with the help of powerful gas burners. The surface when laying euroruberoid should also be prepared: cleared of unevenness, stones and old coating, if any, and aligned. First lay the bottom layer, which goes without a powder.

The roll is held by a hook and heated by its back side with a gas burner, slowly rolling over the roof surface. After the installation of the entire backing layer, decorative (with powdering) is applied over it, just like the previous one. Do not listen to advisers who strongly recommend laying one layer to save money, it is better to do everything on technology, since such a roof device will last much longer.

The duration of the entire building depends on the quality of the roof. Since it is the roof that provides protection from moisture, cold and other environmental influences. A fairly common option for roofing materials are materials roll type. On the features of choice, advantages and installation of the roll roof, we will consider further.

Rolling roof: scope of use and characteristics

The use of flat roofing is associated with the arrangement of the roof, the angle of inclination is from zero to thirty degrees. The number of skates on the roof does not matter. A variant of finishing both flat roofs, and the inclined roof is possible. At the same time, in the process of finishing the surface, removing the old finish is not always necessary. If the roof has a smooth surface before repair, then it is enough to clean up old damaged areas and patch them.

The main advantage of a roll roof is a high period of its operation, which exceeds twenty five years.

In relation to the technology of making roofing materials, they are of two kinds. The first option is used as the main coating, for its production is used cardboard and fiberglass, which is processed with a special composition of tar or bitumen character.

The second version of glass fiber is based on its use without a substrate. In this case, the special mixtures are treated thermally with the addition of various kinds of additives and fillers. Further, the resulting composition is rolled into the web. Therefore, roll materials are of two types:

- integumentary;

- without a basis.

In the second case, the material has a special base, which strengthens its texture with fillers or additives.

Roofing of roll materials is an inexpensive finishing material, the cost of which is much lower than that of alternative roof finishes. Among the advantages of using roll materials, it should be noted - the ease of their weight, while reducing the cost of their installation, storage and delivery to the facility. In addition, installation work is carried out within one day, and for their implementation, two or three people are sufficient. Another advantage of roll materials is that they provide good sound insulation and a high level of fire safety.

For the production of roll materials, materials are used in the form of:

- polyester;

- fiberglass;

- glass wool.

The first option is the most expensive, but at the same time, a reliable basis. To produce it, a polymer fiber is used. This material has a long service life.

For the production of fiberglass fiberglass yarns are used, intertwined with each other. There are two versions of fabrics used in the process of making a roll roof:

- smooth;

- wireframe.

For the manufacture of the first thread, twist together, while the threads are coated with a special oil solution. Thus, it is possible to obtain a surface that is particularly smooth. This version of fiberglass is relatively cheap, however, their incorrect storage leads to deformation of the coating or to the detachment of the bituminous layer.

Structural glass is made up of glass rovings, which are intertwined with glass. This version of the base is not prone to deformation or wrinkling. It is the basis for the manufacture of high-strength roofing materials.

However, the most solid foundation is fiberglass. From its strength depends the reliability of the entire roof. The main indicator of the quality of glass fiber is the type of bitumen substance used to bind the glass fiber.

Roll roofing: basic varieties

We offer you to familiarize yourself with the main options roll coatings, used in the process of finishing the roof:

1. Covering ruberoid type. To create it, a roll base is used. Among its advantages are noted cheapness and ease of packing. In this case, this material is used for roofing for more than 50 years. The use of glassine impregnated with oil bitumen is the basis for the manufacture of roofing material. Due to the fact that the material is very cheap, the duration of its operation is also low. This is the main disadvantage of roofing felt.

2. Another version of the roll roof is rubemast. This version of the guided roof is similar to the previous one. However, the rubast has a special protective film that does not allow the bonding of each layer and provides protection of the face of the material from mechanical damage. Although the material differs for a short period of operation, however, its ease of installation is much higher than in the previous version.

3. The use of fiberglass or polyester materials is the basis for the manufacture of such material as glass refractor. If we compare it with the previous versions, then it has a higher reliability than the cardboard coating, which was impregnated with bituminous solutions. A strong base allows to significantly increase the duration of application finishing material up to fifteen years. In addition, the resistance of the material to mechanical damage also increases.

4. The use of euroboroid is distinguished by excellent frost resistance and resistance to temperature changes. To create a reliable coating, a minimum number of layers is necessary, while the service life of the material is more than thirty years.

5. One of the newest roofing materials is a membrane type coating. Among its advantages are a high service life and resistance to mechanical stress. In addition, special skills or special equipment are not required for the installation of the material. Some of the materials have a self-adhesive basis, for their installation, it is enough to roll the canvas over the roof surface. The only drawback of such materials is high cost, but it pays off with quick installation and reliability of use.

Roof Roof Rollless Type: Features and Characteristics

A soft roll roof is called a cover that rests on the base of the roof, completely repeating its shape, while the degree of protection remains at a proper level. Among the varieties of these materials are:

- insulating coating;

- a breeze covering;

- different kinds of film roofing materials;

To obtain the first option, we use scrap rubber, which is dvuhvulcanized in the environment of bitumen. Next, a fibrous filler, such as asbestos fibers and various additives, is introduced into the medium. Among the advantages of the insulator we note plasticity, resistance to decay, ease of deformation even in frost. In addition, the insulating coating is resistant to biological microorganisms, moisture, differs vapor permeability and plasticity. In addition, the insulator allows you to maintain its properties even at a temperature of -35 + 110 degrees. The main function of this coating is to provide waterproofing of the roof.

Briax coating is also a non-core material, for the production of which rubber and oil bitumen compounds are used, with various additives. More than 55% of the composition of briol takes a bit, 33% of rubber fibers, 13% of asbestos. About 2-6% are plasticizers.

Thanks to the special technology of roll roofing, its resistance to chemicals increases. Therefore, the material is used in the process of waterproofing inclined roofs. Brizol keeps on the surface not only moisture, but also gas compositions.

Briol is supplied in a roll version, its inner part is covered with a fine powder, so material sticking is unacceptable.

Polyisobutylene is a material used for manufacturing GMF. Among its advantages are a high service life and resistance to mechanical stress. The material is used for waterproofing roofs or for creating a multi-layer roofing.

To non-basic materials also include all kinds of films of polyethylene or polyamide. Films have a minimum thickness, full of water resistance and light weight. In addition, their cost is much less than previous versions of roofing roll materials.

Rolling roof installation: technology and instruction

Before starting the installation of the roll roof, a number of preparatory works should be performed, the essence of which is to ensure:

- foundation devices under the roof;

- installation of waterproofing;

- preparation of primer and mastic.

All work is carried out from the top, that is from the site, which is most remote from the place of supply of material. Please note that the amount of laying of the material is directly related to the angle of the roof:

- if the angle of the roof slope is more than 15 degrees, then it is necessary to lay at least two layers of roll material;

- if the angle is from five to fifteen degrees, three layers must be laid;

- in the presence of a gradient angle from zero to five degrees, four layers are required.

Please note that the maximum angle of the roof slope for stacking roll materials is not more than thirty degrees.

All work begins with the preparation of the surface before installing the vapor barrier. Thus, it will be possible to exclude the formation of moisture in the under-roof space. Further it is necessary to equip drainage system. After that, the supply of mastic to the roof begins. When using parchment as a vapor barrier layer, it is glued with mastic.

There are two ways to glue the vapor barrier on the roof surface:

- hot;

- cold.

Please note that cold mastic before heating to the surface heats up to 150 degrees. To apply hot mastic, it will be necessary to heat it up to 220 degrees, and then add the substances in the form:

- talc;

- trembling;

- diatomite.

Before starting work, the roofing material spreads on the roof surface and is cleaned of dust. Then follows its gluing to the surface.

The construction of a roll roof involves gluing together the canvases with the help of a related mastic. That is, when using a material based on bitumen, bituminous mastic is used, for tar roofing - a tar-based mastic.

In the process of laying the roll roof, it is necessary to take into account:

- the slope of the roof;

- the direction by which water flows;

- wind force;

- ambient temperature.

If there is a slope of up to 15 degrees, the material is laid from the bottom of the roof to the top. Otherwise, the gluing is done in the opposite direction, to ensure the optimal flow of water. Note that the roofing is done with an overlap, the minimum value of which is 10 cm.

To perform the work will require two three people, one of which will be engaged in laying the roof, and the second will be smoothed over the surface with a brush and apply mastic. In addition, it is necessary to carry out gluing and fitting of the fabrics, and in order for the roof to lie well on the surface, it will be necessary to have a roller, with which the treatment of the already pasted material is provided.

In addition, in the process of implementation installation works should check the quality of the glued material. This process involves the gradual tearing of one layer from the other. Please note that a small gap is acceptable. If there are small deviations of the roll material, it is allowed to shift it to one side.

Tip: If after the installation of the roof installation, bubbles appear on it, then use an awl or knife to pierce them. Laying layers is done gradually, especially for cold mastics. In case of their application, the waiting time between the laying of each layer is about 10-12 hours.

Installing a roll roof is a rather laborious process, which requires several people to complete. If there is too much work, it is recommended to use special equipment of a mechanical type.

Features of the repair of a roll roofing

If there are deformed areas on the roof surface, they are removed and replaced. There are several reasons for repairing the roof:

1. Presence of blisters.

This problem occurs primarily in the summer. This is due to the strong heating of the roof and the formation of a condensate under it. In this case, just pierce the bloat and wait until the mastic escapes from it.

2. Formation of cracks.

In this case, cracks or tears are cleaned and processed with mastic. Then a ruberoid is glued to the surface. After that, the surface is again greased with mastic and the same roll material is pasted from above, as well as on the whole roof.

3. The presence of detachments.

In this case, the material rises as high as possible, the roof surface is cleaned of dust and dirt, treated with a primer, and then with mastic. Next, the material is again glued to the roof.

Roofing roll material - the most popular way of finishing the roof of any a country house. The modern market offers a wide range of materials, each of which is good in its own way. What to give preference and what to look for when choosing?

Main Categories

All roll materials for roofing are divided according to the type of basis on the basic or non-basic. By the type of components of the coating composition, they are bituminous, polymeric or bitumen-polymer. Cardboard, asbestos, polymers, fiberglass or a combination of materials can serve as a basis, and the protective layer has a fine-grained, coarse-grained or fiberglass structure. All these types of rolled roofing materials are widely used in construction. Let's consider the features of each type in more detail.

Bituminous: cheap and simple

All roofing materials of this type allow the construction of a soft roof. The secret of their popularity is in economy, but because of their short life (only six years), the material is used mainly to cover temporary buildings, rather than residential buildings. Properties of rolled roofing materials based on bitumen are such that they do not withstand the atmospheric effects of sunlight and temperature changes.

Types of bituminous materials

The most popular bitumen material is ruberoid. It is widely used in dacha and individual construction, differing in small cost. is a maximum of seven years, but it is widely used by individual developers. The ruberoid is a roofing material made of bituminous bitumen, which is a roofing board impregnated with bitumen. The upper part has a scaly or coarse granular surface, and maybe even without it. The lower part is pulverulent or fine-grained. Modern roofing felt can be roofing or lining. Mounting involves gluing with hot or cold mastics or using

Pergamum is another material, which is made of roofing cardboard and impregnated with bitumen. The material is thin and less durable than a roofing material, so it is often used as a lining.

Weldable roofing materials

Weldable roofing is perfect solution for arranging roofs of buildings, facilities in the field of industrial and civil construction. Such materials are suitable for waterproofing both roofing, and foundation, floors and floors. The roll roofing material is easy to install, so you can do a lot of work in just a day. Its peculiarity is that as a basis, rot-resistant fiberglass or glass fabrics are used, which increase the strength.

As modifiers of bitumen used polymers, which increase the resistance to various effects and increase strength. The roll roofing material is highly elastic, flexible at low temperatures and high heat resistance. An important role in the deposited materials is played by the structure of the upper layer, whose task is to protect the roof. Roof cover should be a protection against heat, ultraviolet radiation, precipitation. To minimize this effect, a coating is applied.

The roll roofing waterproofing deposited material most often has a powder of different fractions - coarse-grained or fine-grained, scaly or pulverized. As raw materials are used basalt, slate, sand, ceramic crumb. When choosing one should be guided by several factors:

- The complexity of the relief of the roof structure, as well as the angle of its slope.

- Temperature regime in the region.

- The amount of precipitation, which falls on average for the year.

- Possible loads that can lead to deformation.

Bituminous materials for waterproofing

A number of roofing materials serve not only to cover the structure, but also for its high-quality waterproofing. Among them - metal. This material has a three-layer structure: bitumen-foil - a strong roofing covering showing excellent performance properties, with high strength and reliability.

No less popular bitumen roll roofing and waterproofing material called isol. In it, rubber, mineral seals, antiseptic and polymer additives are added during production. Such a composition serves as a guarantee that the material will show increased heat resistance. Suitable for flat shapes and overlappings. Based on the asbestos-cellulose hydroisol is created, the main difference of which is increased rotting resistance. It is widely used in waterproofing basements and areas that are poorly ventilated.

Thus, roofing bitumen roll and deposited materials is a wide choice of coatings that are made in the form of canvases and can be used in various construction sectors. The secret of their popularity - at an affordable cost, as well as increased resistance to various influences.

Bitumen-polymer materials

If the bottom layer in the form of an astringent component is adhered to the overlaying roofing, it will show good waterproofing properties. The roll roofing waterproofing deposited material most often has an astringent component in the form of roofing bitumen and fillers in the form of polymer additives, which affect the increase in service life and performance.

Oxidation of bitumen leads to an increase in heat resistance and a decrease in frost resistance of the coating. To avoid these phenomena, atactic polypropylene (APP) or styrene-butadiene-styrene elastomers (SBS) are added. In this way, the material is a roll polymer-bitumen roofing material. It costs more, but excellent operational properties in combination with high reliability and durability will be to the liking of many owners of country houses.

Features of bitumen-polymer materials for roofing

Two-component roofing materials in the form of rolls have recently been in high demand. They consist of bitumen and polymer, the volume of which is about twelve percent. The basis for this type of coating is polyester, fiberglass, rubber crumb or thermoplastic. Such roofing roll material has a number of features:

- High plasticity.

- Resistance to cracking.

- Possibility of operation in different temperature range.

- High strength.

- Reduced temperature of brittleness.

- Increased softening temperature.

The use of bitumen-polymer coating types is advisable when erecting a flat or with a maximum gradient of twenty-five degrees. Otherwise, the coating can slip. Roofing materials for the upper layer based on bitumen and polymers are presented in several types.

"Monoflex"

This is a multi-layer material consisting of polyester, film, polymerized bitumen as a base and a coating in the form of ceramic chips. Thanks to modified additives, it is possible to improve performance. This material has a number of varieties, the most popular of which are Copprflex coatings with an outer layer of inert copper and Aluflex with an outer layer of aluminum. These coatings are characterized by high heat resistance and durability.

"Isoplast"

Roof material "Izoplast" consists of polymerized bitumen and a base in the form of polyester or fiberglass. It is available in two varieties - roofing and lining. The top layer has a coarse-grained sprinkle on the front side and a polyethylene film on the other, and the lower layer is a polyethylene film that is coated on both sides with a fine-grained fraction. This arrangement of the material contributes to the fact that it acquires flexibility, resistance to breakage at the bend and the formation of cracks. Polymer film from below serves as protection of the coating and guarantees its preservation.

Other bitumen-polymer materials

Any roofing material based on bitumen and polymers has a number of advantages:

- The high quality of the binder component is the key to reliability in any temperature changes.

- High elasticity affects the improvement of flexibility at low temperatures.

- The coating has good adhesion to the powder.

Among the popular materials in the construction industry, one can note roll roofing coatings of the "Technoelast" series. They are produced by two-sided application of a bitumen-polymer binder to a polyester or fiberglass base. It, in turn, consists of bitumen, SBS-modifier and mineral filler in the form of talc or dolomite. A protective layer is created on the basis of a powder of a different fraction and a polymer film. The coating is widely used in the creation of a roofing carpet in various buildings that are operated in any climatic conditions.

Polymeric roll roofing materials

The roll polymer roofing material is created on the basis of petroleum-polymer resins or rubber. These types of coatings belong to the new generation and have durability and high reliability. The period of their operation reaches twenty years and above, and they can cover roofs of any configuration - flat, sloping, gently sloping and even with round slopes. Stacking is performed by strip or continuous gluing based on adhesive mastic, and the preparation of the base plays an important role. Some materials are attached by a load or by a mechanical method.

Polymer membrane

This is a modern roofing roll material, which is increasingly used in the repair and decoration of the roof. Its popularity is due not only to high reliability, but also a wide range of color solutions, resistance to temperature changes and durability, which reaches forty years. This innovative material is a single-layer roof, which is made of flexible PVC with hot air welding. This roofing is different:

- resistance to ultraviolet radiation;

- immunity to the most unfavorable weather conditions;

- resistance to the effects of various bacteria, chemically aggressive substances;

- resistance to decay and decomposition;

- the possibility of creating a coating with a breathable effect.

All this distinguishes this material roll roofing (GOST is set in the technical documentation) from the others.

Types of polymer membranes

Membranes based on PVC are the most common in Russia. They consist of polyvinyl chloride, in which plasticizers are added. Their purpose is to increase frost resistance and give elasticity. The special reinforcing base gives reliability and durability, and the joints are durable and sealed.

Membranes based on thermoplastic polyolefins are an innovative material in which components are added that improve the fireproof and operational properties of the surface. Such membranes are distinguished by a combination of advantages of PVC and rubber. Therefore, they are better combined with bitumen. And this, in turn, affects the greater strength of the material.

Membranes based on EPDM have a high elasticity and the ability to operate for a long time under the most extreme conditions. They are produced reinforced and unreinforced, which is necessary to increase the strength and reliability of the material. In this case, any variety is characterized by elasticity and strength. The kit consists of additional parts, with which you can waterproof difficult areas - sealers, fasteners.

Roofing materials by class

Depending on the longevity, all roofing bituminous materials are divided into several types:

- premium (service life - 25-30 years);

- business (service life - 15-25 years);

- standard (service life - 10-15 years);

- economy (service life - 10 years);

- subeconom (service life not more than five years)

The premium-class materials include the "Technoelast" series. Features of these coatings - the ability to create a breathable roof, from which moisture will be removed, which has the ability to reduce the longevity of the roof. With the help of this type of materials it is possible to equip a single-layer roof covering, solving the problem with blisters and making the installation itself easier and more convenient. To arrange the lower layer of the roofing coating, you can use the "Technoelast Fix", which makes it possible to mount a roofing carpet on the base. The roof will be resistant to deformations and capable of withstanding heavy loads. The operational features of the coating are such that it can be used in regions with any climatic conditions.

Among the materials of the business class can be identified two - "Unifleks" and "Ecoflex". The first is good because it serves as an effective protection against moisture penetration, contributing to the durability of the structure. Both that and other materials are a waterproofing sheet that provides ventilation of the roof. "Ecoflex" - an excellent solution for underground structures. This roofing roll material is advisable to apply in regions with elevated temperature regimes. Due to its quality and reliability, it will serve as protection of the roof for a long time.

Among the materials of the standard class, Bipol is in demand. It has a strong, non-spinning base, which is coated on both sides with bitumen-polymer binder of high class. On the basis of this material, it is possible to equip a roof with a small slope, to waterproof the foundations of buildings and structures.

Economical types include "Linocrom K", with which the upper layer of the roofing carpet is arranged. It can be used both in the lower layer of the system. The protective layer is made by fine-grained dust or polymer film.

"Bikrost" - a popular material, which is a waterproofing sheet with a solid foundation based on bitumen binder. It is used for the installation of the lower layer of roofing carpet. The protective layer is provided with a fine-grained powder or film. The cheapest roofing roll material is parchment. It is a roofing cardboard, which is additionally impregnated with oil bitumen. On the basis of this material it is possible to repair and equip the roof with a service life of a maximum of five years.

conclusions

As you can see, modern manufacturers offer a wide choice of roofing roll materials. Each of them has its own technical and operational features, each designed for a specific design of the roof. That is why it is so important to consider the composition, application features and climatic conditions of your own region. All this in combination will allow you to select the most suitable building material for the specific conditions.

Lately roll roofing It is used quite often not only on industrial buildings, but also on private buildings.

The main limitation of its use is the slope of the roof itself, which should not be more than 30 degrees.

The advantages of this coating include:

- long time of operation;

- simplicity of installation;

- quick repair if necessary.

In addition, such a roof has an aesthetic appearance, has waterproofing properties, is not afraid of wind and impact loads.

Soft roof is optimal for flat roofing, but can be applied to those that have a slight slope.

Types of roll roofing

The appearance of a soft roll roof is a material rolled up into a roll. For its production, a special technology is used, which is developed in two different ways.

The first type is a coating based on cardboard or fiberglass. On it, a special way is applied a fused knitting mixture in the form of tar or bitumen.

For the second type, the basic material obtained by heat treatment is used, some mixtures of special fillers and additives, which are subsequently rolled out in a special way into the webs.

All roofing materials must necessarily comply with SNiP, and their production technology must be observed exactly.

Coiled roofing materials include the following types of coating:

- The ruberoid, which is made on the basis of cardboard. It has a relatively low cost and high waterproofing properties;

- Rubemast, made by the type of roofing material. It has a similar composition, but it contains a protective film, which is superimposed on the welded parts;

- Euroruberoid. Its main advantage is that it perfectly withstands temperature changes, severe frosts, and also has a tight angle of abutment;

- Membrane coating - a novelty in the class of this type of roofing materials. It is marked by high durability, quickly mounted. The technology of its production is based on the latest developments;

- Coating is also considered a roll roof. Isol is the result of processing scrap tires. This material has high waterproofing, elasticity, ductility, water resistance;

- Brizol - a roll roofing material is obtained from a mixture of petroleum bitumen, which is able to withstand not only water, but also various gases, has a dense slope of contiguity.

Polyisobutylene is made of GMP coating, which has high quality indexes, which affects its durability, as well as optimal waterproofing properties.

Also to the roofing materials of the roll type is a polyethylene film, however, it has a number of significant drawbacks and an incompletely dense slope of contiguity.

How to choose a roof covering

All kinds of such a soft roof are used for flat and with a slight slope of the roof. They have their own designation, which consists of some numbers and letters.

To choose such a covering for roof arrangement follows, on the basis of its purpose and recommendations of SNiP, which will subsequently increase its service life.

The roofing device made of roll materials allows solving a number of tasks to increase the waterproofing of the roof.

This coating, due to its specific properties and deposited base, is easy to install, and if necessary - quickly repaired without serious investment.

If we compare the roll roof with other similar materials, then it has a relatively low cost.

In addition, it has a small weight and dimensions, which makes it possible to reduce transportation costs.

Mounting technology of this material with a fusible base does not cause special difficulties, as well as in its subsequent maintenance.

All work related to the construction of a roof with a soft roll roof, as a rule, does not take much time and does not require the involvement of a large number of workers.

Such a coating, laid in accordance with the requirements of SNiP, increases the waterproofing properties of the roof.

Advantages of a roll roofing

If the roll roof conforms to the SNiP and is laid down by all rules, then it is possible to guarantee a low noise level, excellent waterproofing properties, and besides, all defects will be hidden.

To all listed advantages it is possible to add full conformity to the highest requirements for fire safety.

Modern roll roofing with a weldable base can serve without serious repairs for at least twenty years, and possible defects can be eliminated in a short time.

If a disassembly of the coating is required, then this will take a minimum period of time.

Roof installation of roofing type

Before proceeding with the installation of a roll roof with a weldable base, it is necessary to draw up a preliminary plan of all the work, in which the recommendations of SNiP will be taken into account.

It must reflect each surface node, take into account possible defects, calculate the angles of contiguity to the parapet.

The video below shows the material about the device of a soft rolled roof.

This work card will help not only to facilitate labor, but also to reduce costs.

Beforehand, the roof must be cleaned of debris, all present defects are eliminated, the slope is calculated.

It should be remembered that for a flat roof and the one on which the gradient is up to 5 degrees, it is covered in 4 layers of roll roofing. With a slope of up to 15 degrees - in 3 layers.

For this type of roof, the surface must be flat. Despite the fact that it is self-adhesive, under it there should be no debris and defects. All technology of this type of work is detailed in the SNIP.

Important! Before the start of laying, the rolls must be rolled out and held in this condition for 24 hours, while the surface to be welded should be at the bottom.

During installation, you must ensure that all nodes have a minimum overlap, and on a flat roof it can be slightly smaller than on one that has a slope.

It is necessary to avoid the abutment of rolls to each other, since this can cause subsequently various defects.

The video below shows the installation of a soft roll roof.

The map, which was compiled before the beginning of the work, should take all this into account. Two people can cope with the installation of the roll coating.

At the first stage of the work, regardless of whether the flat roof or has a slight slope, part of the roll is adjusted to the surface area, all angles and junctions are checked, including the parapet.

After that, the roll turns away and onto it, as well as on the roof surface, a sticky base is applied. Further, the technology involves gluing the roll to the base.

Each node is carefully smoothed out. It must be ensured that there are no defects. Then the process repeats until the entire roof is covered.

In the event that technology is disrupted at some site, disassembly and re-laying of the coating must be carried out.

Repair of the roofing of the roll type

In the process of exploitation of the roof, the material of its roof can be violated for various reasons, which will necessarily affect the waterproofing.

Trust the repair of the roll roof should be those who have experience in this field.

First, you should identify all the defects present, check each node and the angle of contiguity to the surface.

The welded surface, its condition and composition are also monitored. Before you start all the restoration work, you need to make a plan.

In addition, a corresponding map should be developed in accordance with the SNiP.

The plan and map of work should take into account the scope of work, composition and types necessary materials. Work begins with the fact that the dismantling of damaged areas is carried out.

In addition, the technology provides drying of the surface, all identified defects are eliminated.

After complete disassembly, it is necessary to cut the web material into the appropriate pieces.

Then, if technology and plan require it, the adhesive composition that is applied to the surface and material is heated.

All areas of contiguity of the old roof to the roof must be carefully tampered with.

All edges and angles of contiguity along the parapet, if any, as well as each node, must be carefully processed and smoothed.

If small defects appear during the works, then disassembly must be carried out, after which the roofing is re-laid.

Of course, it is easier to make work on a flat roof, but if there is a slight slope, problems should not arise.

In the event that a slight damage is detected, the disassembly of the flat roof surface and the one that has the minimum slope may not be performed.

At the same time, the plan and map of the work may also not be compiled, which is allowed by the SNiP.

Repair, in this case, is carried out by liquid rubber, to which all the damaged nodes are processed.

It can also be walked around the parapet. There are types of roll coating, the basis of which is self-adhesive.

They can be used for repair work, when roof dismantling is not necessary.

The video below shows the repair of the roll roof (soft) with mastic.

In most cases, different kinds of roll coverings are used for a flat roof. They quickly fit and easily repaired, while not completely disassembling the old surface.

This material is sufficiently durable and provides high waterproofing performance of the entire roof, if laid in full compliance with the requirements of SNiP.

In addition, the construction of a roll roof assumes its use in different climatic conditions.

The roll roof is a practical roof covering, which was previously used more actively to cover the roof of production or household buildings because of low decorative potential. However, an affordable price, a simple installation technology and excellent insulation properties made the roll materials attractive for private housing construction. Since its inception, the soft roof has changed a lot, it has become stronger and more durable, so it is considered a real alternative to metal, asbestos-cement or ceramic coatings for covering flat and low-slope structures. In this article, we'll talk about the cost, structure and types of roll roofing.

Soft roof - a group of roofing materials, the layers of which are pressed into a long cloth, and then rolled up into a roll. Roof coverings for the roof are easy to store, transport and lay on the ramp, so they are popular in industrial and civil construction. Soft roof has the following device:

- The basis. The basis of the roll materials for roofing is fiberglass, fiberglass or roofing cardboard. It provides strength, flexibility, coverage.

- Impregnation. The soft roof is impregnated with tar, bitumen or a viscous polymer substance, which gives a moisture repellent to the coating and protects against temperature changes.

- Armor plating. On top of the roll material for the roof is applied a powder, protecting from mechanical damage and exposure to ultraviolet rays. Powder is made of quartz or silica sand, stone or mica chips.

- Bottom layer. A protective coating of a fine-grained or pulverized fraction is applied from the bottom to the roof covering. It is necessary that the layers of material in the roll do not stick together during storage and transportation.

Note! Different for the roof are significantly different in composition. The most accessible and known cover since the Soviet times is the roofing felt and bare, the low cost and practicality of which is valued to this day. The price of more modern membrane roll materials for the roof is much higher, however, the perfect installation technology and long service life justify an impressive cost.

Advantages

The device of the soft roof resembles a multilayer pie, the layers of which are closely adhered to each other, forming a strong, hermetically and practically seamless coating. It is suitable for a roof with a slope of 1 degree. Roll materials, in contrast to metal, ceramic and asbestos-cement, can be used to erect a flat roof. They are characterized by the following advantages:

- Resistance to moisture. implies impregnation of cardboard or fiberglass base with bitumen, which perfectly protects against penetration of moisture, in addition it is a rather strong antiseptic.

- Affordable price. The cost of roll roofing is quite low, because they are used even for economic and production facilities without damage to the budget.

- Resistance to temperature changes. Soft coatings tolerate temperature changes well, without deforming, which makes it possible to perform a roll roofing device in all climatic zones.

- A light weight. The roll roofing, whose layers are stacked on top of each other, weighs less than many other roofing materials, so it almost does not burden the roof truss.

- Ease of installation. The technology of laying bitumen and polymeric materials is quite simple and allows you to perform installation even with your own hands.

- Low noise. The bitumen roof absorbs well the noises that arise during rain and wind.

Please note that low price and weather resistance are not the main advantages of bituminous roofing. Their most useful quality is flexibility, which allows you to easily lay materials on the surface with a complex terrain. The disadvantage of flexible roofing is considered to be a slight flammability, which increases the risk of fires. The early ones often spontaneously ignited under the influence of direct sunlight on hot days, but now such a problem with bituminous coatings does not arise.

Bituminous flexible coatings

The most common type of soft roofing is considered bituminous materials, which are distinguished by an affordable price and high practicality. This category includes such well-known coatings as roofing felt, roofing felt, rubemast. Their peculiarity is that ordinary or modified oil bitumen is applied to impregnate the substrate. There are the following types of bituminous coatings:

Important! Bitumen roofing materials are highly durable and practical, so they are in demand. Layers of ruberoid are stacked on each other so that a sealed and durable coating is obtained, by fusing or gluing.

Membrane coatings

Membrane roofing is a new word in the construction business, they differ significantly from traditional bituminous materials by composition. Roofing membranes do not have as such a foundation, so they are thinner, lighter and more flexible. Depending on the polymer used to make the membrane, they are divided into the following types:

Remember that the roofing membranes are not mounted in the same way as the floating roof. No heating equipment is used for laying the canvas. Adhesive layer of low-melting rubber bitumen melts at an ambient temperature of +5 degrees, so that the coating is glued to the base of the roof.

Ways of installation

The roll roof is mainly used for the construction of flat and low-grade saddle roofs. For installation, a continuous crate of moisture-proof plywood, OSB or edging board, concrete is being built. It is important that the base on which the canvas is laid does not have unevenness, since they will damage the flexible materials in the course of friction. There are the following types of roll roofing:

Remember that the welded and self-adhesive roof is mounted at an ambient temperature of at least +5 degrees, as melting bitumen in colder weather is problematic. Therefore, in the cold season, the device of flat roofs is performed by gluing using mastic.