On a warm summer day, I do not want to leave the green lawn and go on vacation to the house. No matter how comfortable your dacha was, the opportunity to sit outside is more valuable than staying in four walls. That is why garden swings made of metal are so popular among owners of cottages and cottages today.

Ready-made assembly constructions can be purchased at the store, but it's much more interesting to make them yourself. This will give you the opportunity to introduce your own original solutions and show your talents in the field of exterior decoration.

Variants and modifications of the garden swing developed a great many, so the home master does not have to start from scratch.

We suggest to get acquainted with the most interesting developments of garden swings. The choice of the optimal solution is yours.

Possible variants of garden swings from metal

The classic design of the garden swing is a bench suspended on chains or rigid metal rods. Next we enter the field of creative searches, each of which ends with the creation of an original design.

Considering the pattern of simple swings made of metal, we can conclude that the simplicity of the construction is not synonymous with comfort.

On such a swing, you can relax only if the yard is quiet and sunny. Wind and rain will interrupt the idyll of rest, since there is no roof, no side fences here.

Therefore, the most widely used metal garden swing, over which is installed a canopy. A soft seat and a backrest will not be superfluous, if it is a question of quiet rest.

As for the decor, you can say that any metal construction is perfectly combined with delicate forging, wooden seats and a transparent polycarbonate canopy. The visor should be made lower and wider so as not to get wet in case of heavy rain.

He who slept in a summer night under the open sky, will not exchange this pleasure for a home bed. Install a lightweight mosquito net on the country swings and you will sleep in the fresh air sweetly and firmly, like a child. The mesh curtain will soften the gusts of the wind and scatter the direct sunlight.

Very decorative, you can even tell fabulously look forged garden swing, intricately decorated with steel ornament and decorative lights. The visor for them is best made not of metal, but of polycarbonate.

Fans of original designs will appreciate the unusual and comfortable options of garden swings. As we see, in this design, you can perfectly do without a bench, hanging a comfortable chair to the support post at one point.

Such an unusual combination of a beach chaise longue and a swing will appeal to many summer residents and owners of estates.

Another interesting solution is a garden swing with a hammock. They do not have a backrest. She just does not need those who want to stretch out on a soft couch and rock on him, lulling herself.

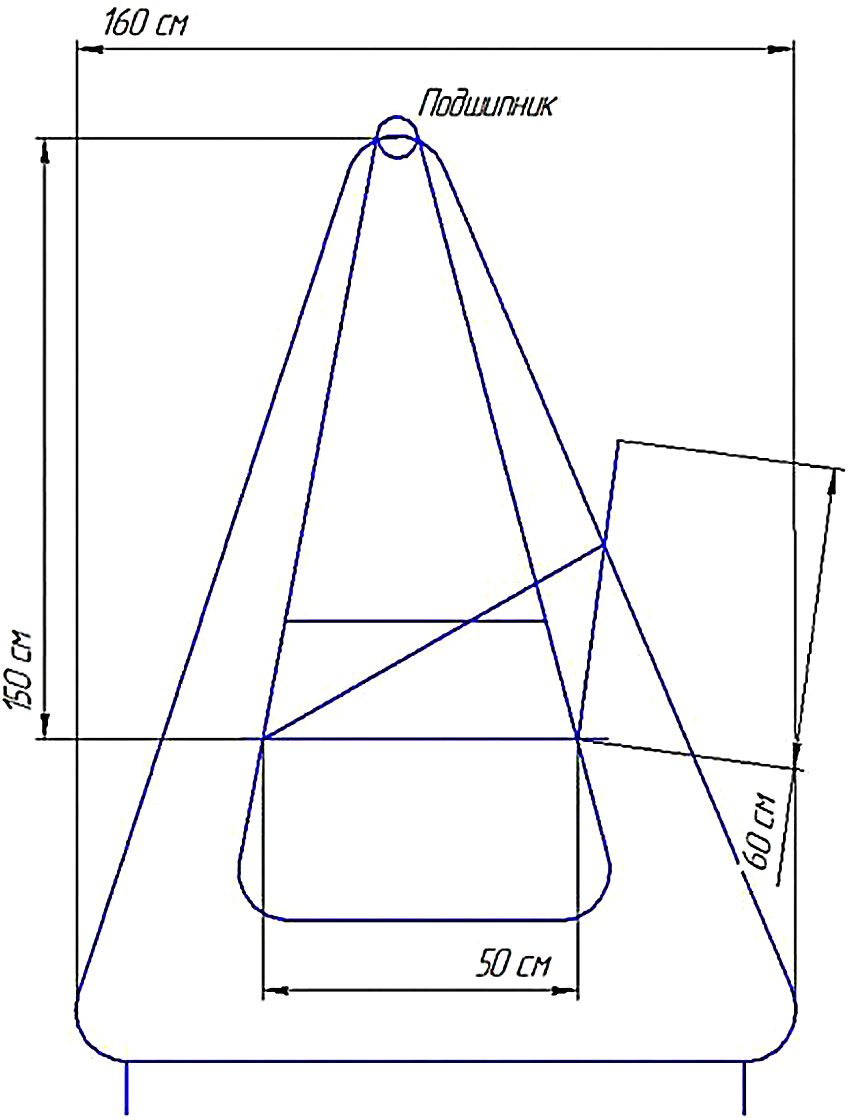

You can hang a swing on two chains, or you can on one. So you will get an interesting installation, called a swing chair. One fixing point allows not only to swing in any direction, but also to rotate around its axis.

The main thing is not a suspension, but a convenient base. Here is the motto of the developers who came up with a very simple and original design. These swings consist of a single openwork metal chair, suspended from a rope to a solid branch of a tree.

Rest, so relax! So decided the designers who developed the next version of the garden swing. As we can see, there is a small table for drinks and desserts. For the feet are invented separate pads, allowing tired men to stretch out into the whole "heroic breadth".

Having considered the most interesting variants of garden swings, let us turn to the practical part of our article. In it, we'll talk about how to make a swing of metal with your own hands.

A small children's swing or a swing for the whole family?

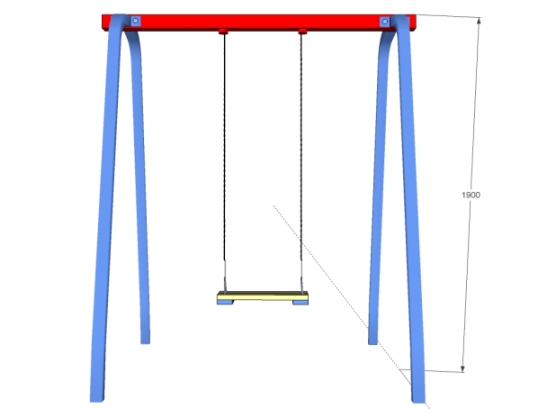

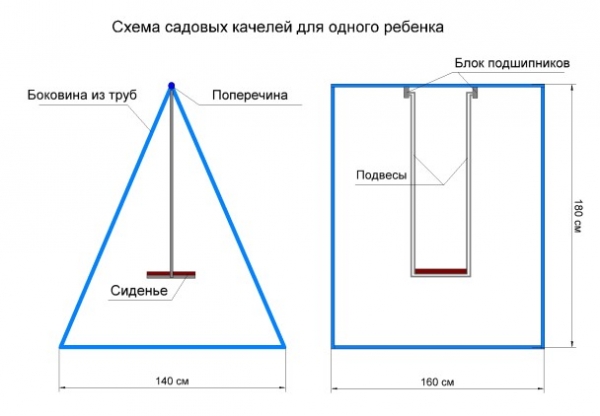

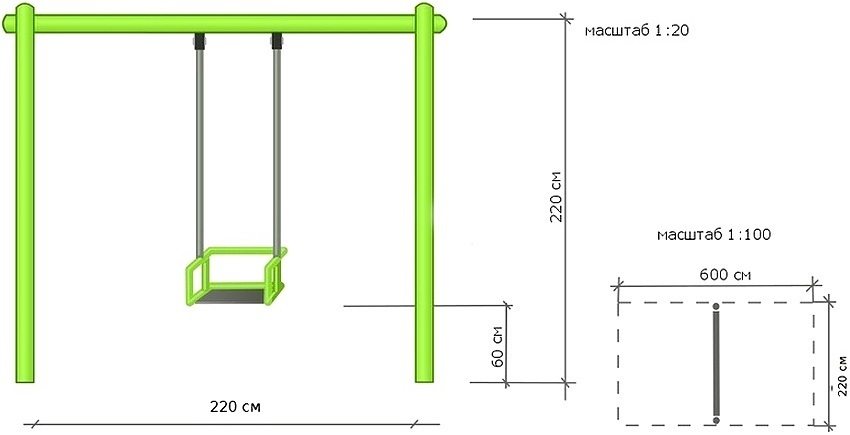

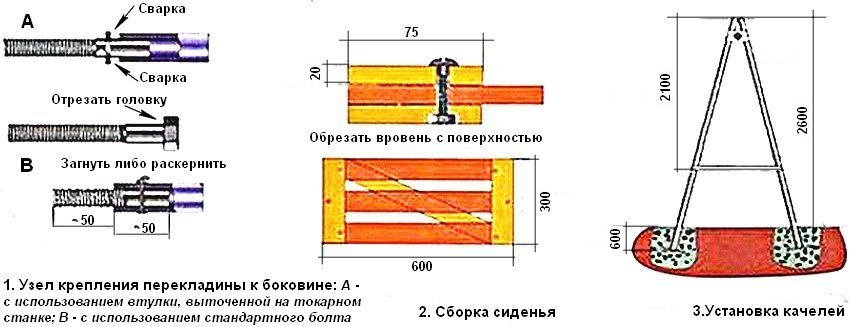

The first step to be taken by a domestic craftsman is to choose the option of a future swing. If you want to please the child, then make for him a single metal construction - the "seat on the chain".

Such swings are assembled from four curved profile pipes and a central cross member, to which a seat is attached on a chain or on a cable. The advantage of this solution is the ease of assembly and disassembly. At the end of the summer season, the structure can be dismantled and folded into a barn.

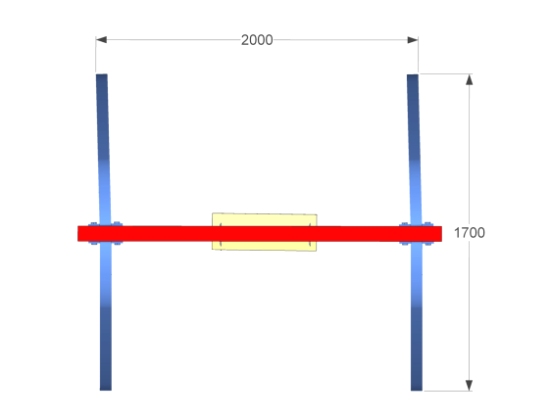

If you are satisfied with a stationary version, then making a garden swing for a child can be done a little easier. Having bought several metal pipes (diameter 1.5-2 inches), two supporting sidewalls with a lower spacer are welded from them. To them on welding the upper cross-piece from a piece of a pipe fasten and do in it two apertures for installation of eyes.

Instead of eyelets to the crossmember, two steel clips with bearings can be welded. In this case, instead of the chain, smooth steel rods are used, to which the seat base is rigidly fixed.

To increase safety, attach the backrest to the seat. It can be assembled by welding from pieces of a corner and lined with a wooden strip.

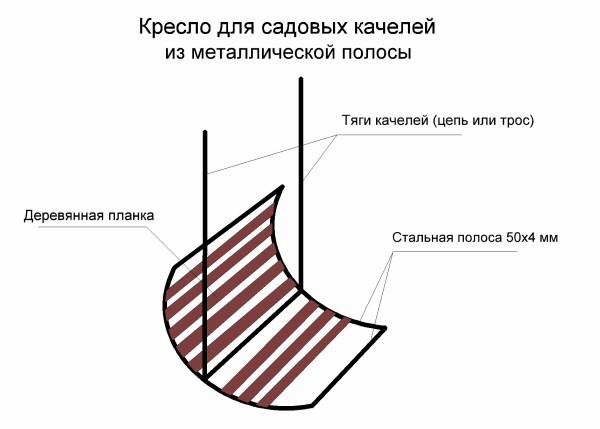

Looks like a self-made seat-armchair, the drawing of which you see below. Its base is two bent steel strips connected by transverse stiffeners.

For the cladding of the metal base, you can use planed oak rails, treated with stain and covered with varnish.

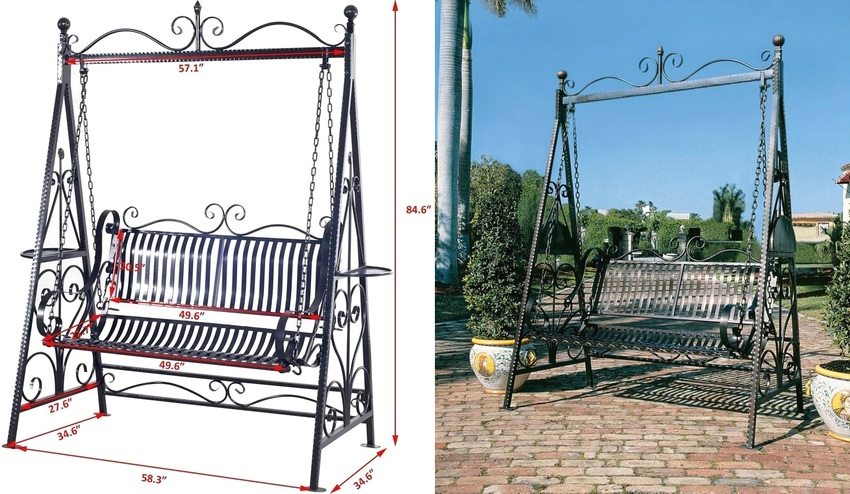

Before you make a homemade swing, think over the basic dimensions of this design and check for the safety of the dimensions of the finished factory products.

A version of a homemade swing made of metal with a visor

The width of the garden swing should be sufficient to accommodate the bench. The visor, as we have already said, is better to be made wider and lower to protect yourself from sudden rain.

The dimensions of the sidewalls and the height of the swing should be selected for reasons of maximum stability and rigidity. To improve these characteristics, it is possible to concrete in the site threaded anchors, to which after the completion of the assembly will be attached to the pillars of the racks.

Very often, when building a courtyard of a private house or a garden, a swing is installed. Similar constructions are made of wood, automobile tires and other improvised materials. But in order to achieve a truly qualitative result, use drawings and photos of garden swings with your own hands made of metal: the dimensions and performance characteristics of these products allow them to be used for a long time.

- 1 Classification of garden swings with their own hands made of metal: photos and features

- 1.1 How to make a garden swing with your own hands made of metal: photos and examples of products

- 1.2. A photo of a garden swing with your own hands, created by forging

- 1.3 Characteristics of garden swings with their own hands made of metal

- 1.4. The cons of a makeshift swing for a dacha from metal

- 2 Drawings and photos of garden swings with their own hands made of metal: dimensions and technology

- 2.1 A brief classification of garden swings with their own hands made of metal

- 2.2 The technology of creating a swing with your own hands from a profile pipe

- 2.3 List of necessary tools and materials

- 2.4 Drawings and photos of the swing with your own hands made of metal: the preparatory stage

- 2.5 Assembly according to the drawings of the swing from the profile pipe by one's own hands: the frame part

- 2.6 Technology of assembling a wooden seat for a swing

- 2.7. Manufacturing of the visor for the construction

- 2.8. The final stage of construction

Classification of garden swings with their own hands made of metal: photos and features

Various materials are used for the construction of metal structures. So there are so many design solutions. This is evidenced by numerous photos of garden swings with their own hands of metal, which can be found on the Internet.

For the manufacture of structures the following materials are used:

- corners of metal;

- profiles of the square form;

- i-beams (steel beams);

- pipes (profile of the round form);

- brands (aluminum profiles).

Before you start planning and developing drawings of garden swings with your own hands made of metal, you need to decide on the type of future design. To do this, you can study the ready-made systems offered by modern industry.

How to make a garden swing with your own hands made of metal: photos and examples of products

If you are puzzling over how to make a swing with your own hands for children, take as an example the options for factory production. Such products have a properly designed design and are represented by a large number of interesting design solutions. It will be enough for you to create similar swings from improvised materials.

Classification of products from manufacturers:

- garden design of a stand-alone type. This kind of products can be installed in any place that you find suitable, as they do not need to manufacture additional support or hangers. Swings of this type can be not only metal, but also wooden;

- sofa swings that can be used by both adults and children. In the second case, the product allows you to simultaneously sit on a bench with just a few skaters. The structures are comfortable and safe, equipped with a comfortable back. For a period of heavy rains or in winter, the swings are easily removed, since their construction has a block structure. Products can be metal or wooden;

- designs, complete with a folding back and a mosquito net. They can be used as children's metal swings for cottages. You can add other accessories to create extra comfort;

- swing, made by forging, which have many advantages.

Photo of a garden swing with your own hands, created by forging

Swings of this type are performed mainly for installation in the territories of country houses. To create these products you will need skills in handling the welding machine and metal or you can hire an assistant. In this case, the swing turns out to be more durable and powerful than other versions of metal structures. In addition, you get an original product that can become an interesting decorative addition to the landscape and the exterior of the house.

Scheme with mounting dimensions of garden forged swings (1 inch = 2.54 cm)

Metal products made by forging are of high cost. But it is justified by its excellent decorative characteristics.

Characteristics of garden swings with their own hands made of metal

Metal structures have the greatest number of advantages compared to products made from other materials. That's why on the Internet there are so many photos and drawings of children's swings with their own hands made of metal.

Technical and operational characteristics of the metal-based swing:

- long service life is one of the main advantages. Metal is not subject to the harmful effects of factors such as, for example, decay processes. The breakdown due to drying also is excluded;

- practicality - environmentally damaging effects on buildings (ultraviolet radiation, rain and other types of precipitation) can not affect the strength characteristics of the material;

- reliability - due to the increased strength of the metal and its durability, the resulting structures are very strong;

![]()

- budgetary - metal in procurement has a lower cost than wood of high quality level (low quality wood can not ensure the strength of the product, so it does not apply to create a swing);

- a variety of modifications - the range of modern swings that can be purchased or performed independently, is extremely wide, which allows you to choose a design that fully meets individual preferences.

Minuses of self-made swings for dachas from metal

Despite the external appeal of metal products, in themselves they can not harmoniously fit into the landscape of the suburban area, as is the case with the swing of wood. This will require a stylistic support for their design, adding similar elements to the exterior of the house or garden.

One of the positive characteristics of the material, namely the hardness of the metal and its strong structure, can be considered as a drawback. On the one hand, strong and solid swings are what you need for a dacha, on the other - they can cause serious injuries that a person can get due to a stroke. In comparison with wood, soft in nature, metal is times more dangerous.

Metal products are susceptible to corrosion. Rust can lead to a gradual breakdown, so the durability of the structure can only be ensured if properly maintained. To prevent corrosion, it is sufficient to cover the metal in a timely manner with a layer of coloring compound intended for metal surfaces and outdoor operating conditions.

Drawings and photos of garden swings with their own hands made of metal: dimensions and technology

Hand-made garden swings can have a different type of carcass. On the basis of this feature, the following designs are distinguished:

- collapsible;

- welded.

Welded types of swings require the use of a welding machine and other special equipment. As a result, you will get a strong and stiff supporting part that will allow you to operate the structure for many years without any risk to your health.

If you do not know how to handle a welding machine, choose a swing with a collapsible construction. The principle of assembling the frame is to twist all elements of the product with bolts and nuts. Everyone can do a similar job.

A brief classification of garden swings with their own hands made of metal

The simplest way to create a design for ready drawings of garden swings with your own hands made of metal. Considering the schemes, you can see that the configuration of the supports is different.

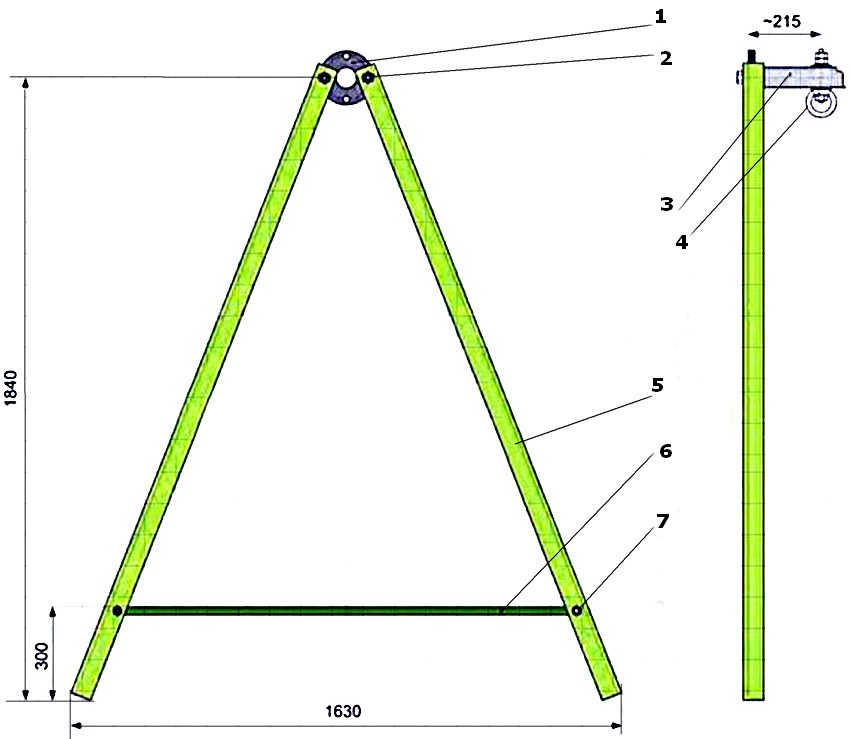

The A-shaped carcass base consists of two bars, which are connected together in the upper part. Approximately in the middle of their height there is a jumper. It is designed to increase the rigidity of the structure. There are supports without a bridge, which are L-shaped.

Another type of support - the elements with a crossbar, forming the base of the U-shaped. Creating such a design takes less effort, but the swing turns out to be less stable. Their operation will be long and safe if the foundation supports are placed in deep wells in the ground and well concreted.

In addition, all metal products can be divided into two groups:

- stationary - the supporting part of the swing is securely concreted;

- portable - fixed using anchor bolts or curled reinforcement, which is hammered into the soil.

Technology for creating a swing with your own hands from a profile pipe

Suspended swings are considered the most common designs. They are comfortable, practical and comfortable. Equip the product with a canopy protecting it from direct sunlight. Thanks to this, the seat will not overheat, and the skiing process will become even more comfortable.

To make a canopy for children's swing from metal, textiles, tarpaulins, soft-roofed wood in the form of a roof can be used by their own hands. But the most suitable material is cellular polycarbonate. Polycarbonate sheets are transparent, so under the canopy it will not be dark. At the same time they perfectly scatter the direct sunlight.

List of necessary tools and materials

Before you make a garden swing with your own hands, take care of the availability of appropriate tools:

- bulgarians;

- construction level and roulette;

- welding machine and protective equipment (for working with the device);

- electric drills;

- a set of drills designed to work with metal and wood surfaces;

- screwdriver;

- a set of wrenches;

- self-tapping screws designed to fix sheet polycarbonate.

For the work will also need to purchase materials, namely:

- metal profile (pipes and corner);

- boards or bars of wood for seat assembly;

- bolts equipped with semi-hollow heads (for seat assembly);

- washers and nuts for bolts (for seat assembly);

- elements for fastening in stainless steel or with galvanized coating (carabiners, suspension brackets on bearings, eyebolts, chains);

- anchors or bent reinforcing bars with a long length (to fix the structure on the base);

- a sheet of cellular polycarbonate (roof of a canopy);

- protective means for the frame (primer with anti-corrosion properties and coloring composition for metal surfaces);

- protective means for wood, from which the seat will be created (stain, varnish, set of brushes for surface treatment).

Drawings and photos of the swing with your own hands made of metal: the preparatory stage

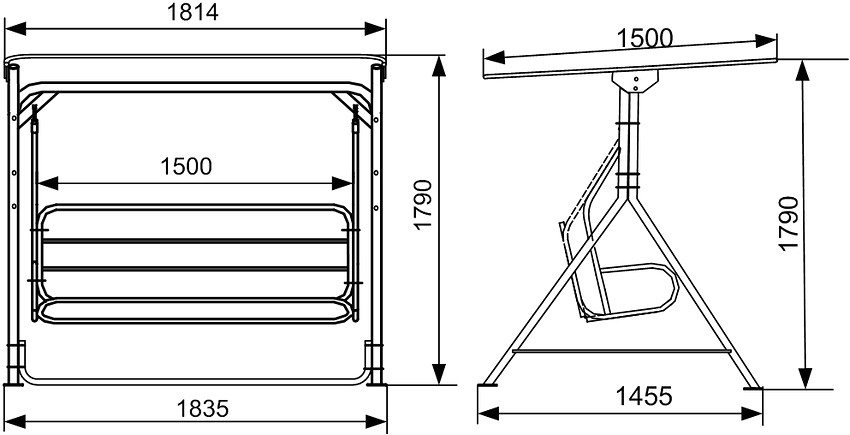

At this stage, a zone is selected for mounting the swing, the dimensions of the structure are determined. The optimal size of the pendant bench is 1.5 m. This is enough to allow the swing to accommodate two skaters or lie down to one.

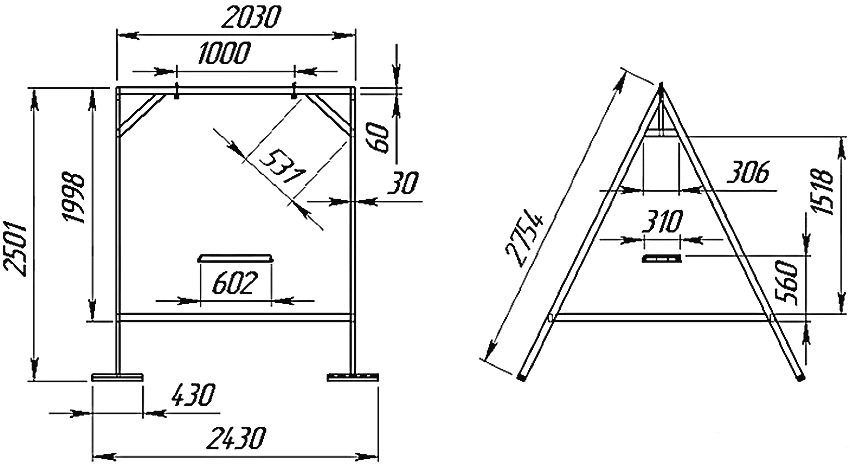

According to the drawings of the garden swing with their own hands from the profile, the structure consists of the following elements:

- support frame of rectangular shape in the base;

- sidewalls made of a pair of pipes, fastened together by a welding method;

- horizontally located crossbar for hanging the bench.

This information will help with further assembly. Thanks to this structure, the structure acquires the necessary level of rigidity. Correctly picking the width of the base, you can build a very stable product. Take for the basis of your work the rule: the larger the angle that is at the top of the triangle between the base and the sidewalls, the more stable the design will be.

The general dimensional parameters are calculated on an individual basis. Under them, adjusted for the visor of polycarbonate and a pendant bench. Specialists recommend compulsory preparation of drawings with the indication of all dimensional parameters of the structure, so that it would be more convenient to work with the material. Subsequently, this will save you from mistakes and save time.

Assembly according to the drawings of the swing from the profile pipe by oneself: the frame part

It is recommended to start the work on assembling the frame from the side parts. To do this, on the basis of the drawings, it is necessary to mark the pipes and cut them with a Bolgar. Before assembling, check the accuracy of the dimensions. All four elements of the sidewalls should be similar to each other. They need to be connected in pairs, using the welding method. As a result, you should get two identical L-shaped parts.

Then the sharp end, located at the top of each of the parts, is sawn off at one level. This procedure is carried out in order to form a small support area for fixing a horizontal crossbar.

The width of the support frame (short side) should be equal in size to the distance that is formed between the pair pipes of the side parts of the structure. The welding machine welds the sidewalls to a rectangular supporting frame, and then the horizontal crossbar (over the side racks).

All stages of assembly of the frame part must strictly obey the laws of geometry: the side racks have a vertical type of arrangement, the horizontal crossbeam (beam) intended for hanging the bench runs parallel to the base. To control the assembly parameters, use the building level.

![]()

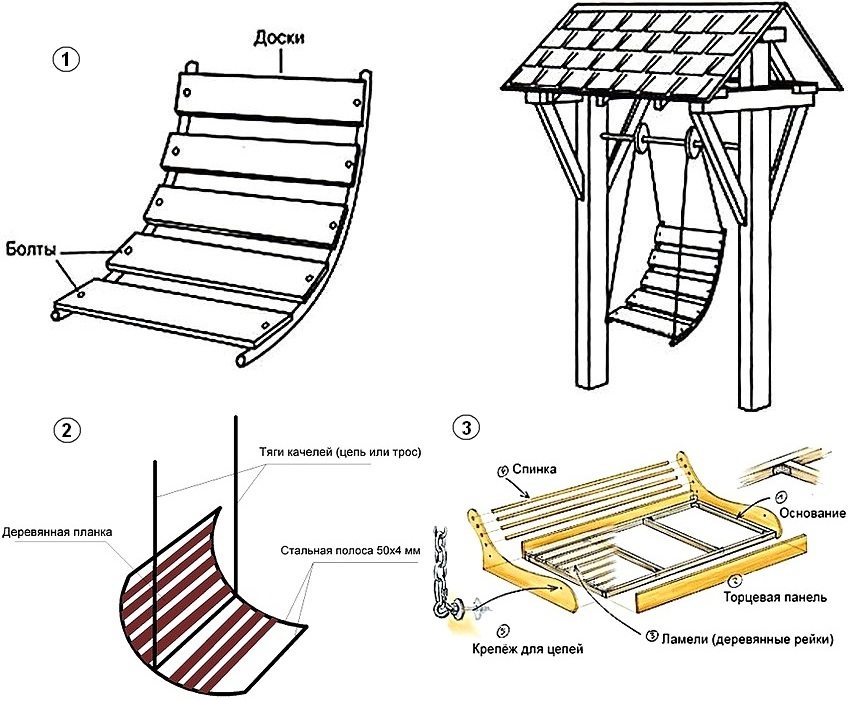

The technology of assembling a wooden seat for a swing

Building a bench is an important stage of construction. Especially if you create a child's swing from metal by drawings with your own hands. At the base of the seat there should be a frame base made of a steel corner. To get a bench with a comfortable back, position it at a certain angle with respect to the seat. The optimum angle is 120 °.

To make the correct bend of the corner, make a cutout in the form of a triangle (60 °) on one shelf. The frame part for the seat is made of a rectangular metal profile using the welding method. The side parts should be connected along the edge zones with the help of horizontal bridges. The connection area must be in the same place where the structure is bent.

Regardless of whether you are building a swing with your own hands for children or are making adult products, the backrest and seat should be completely smooth. For these purposes, suitable wooden bars or boards, carefully treated with sandpaper (first a large grain, then a small one).

The boards are cut to the required size and fastened to the frame through pre-made holes with bolts in such a way that their heads are recessed. Before the final assembly of the structure, the wooden elements are treated with an antiseptic and lacquer compound, and the metal elements with a primer and paint.

In the corners of the frame part of the bench are mounted eyebolts. Chains will be attached to the ears of these bolts with carbines or threaded couplings. To suspend the bench, you also need to install eyebolts at the corners of the product or over the edges of the seat.

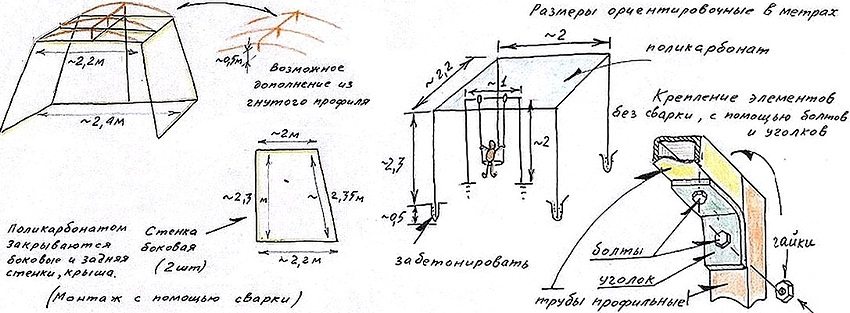

Fabrication of the visor for the construction

The process of manufacturing a visor is not mandatory. But if you create a swing design for your children, you should think about the comfort and protection from the scorching sun, as well as the atmospheric precipitation.

To do this, you need to make a rectangular construction, which will be based on a metal frame, reinforced by bridges. A sheet of honeycomb polycarbonate is fixed over the structure. The installation of the visor is carried out at a slight angle, so that the sediments will freely flow down.

Take several metal profiles with a square section of a small size to make the skeleton of the visor. All these elements are welded together, after which the visor can be attached to the upper frame of the swing. This is also done with a welding machine.

When all work on the assembly is completed, the design is subject to final processing. The surface of the swing is covered with a primer, then it is painted in any color you like.

The final stage of construction

When the paint is completely dry, a sheet of polycarbonate is attached to the frame of the visor. To do this, use self-tapping screws with sealing washers.

A wide range of colors is one of the advantages of polycarbonate. You can choose the color of the visor under the color of the swing, or, conversely, make it contrast. Moreover, the coloring of the material has a direct effect on the level of dispersion of the sun's rays.

The finished product must be securely fixed on the concrete site. If the installation of the structure is carried out on the ground with a high density, several clamps made of reinforcing bars can be used to fix the frame. Beforehand, it is necessary to sharpen the ends of the clamps, which will make it possible to drive the rods into the ground for 0.5 m without problems.

It is better to use anchor bolts as a fastener on a concrete pad. They are installed in advance in the appropriate places. After twisting the nuts, cut off the excess thread with a Bulgarian. This concludes the construction of the structure.

Swings made of pipes, made by themselves, are 2-3 times cheaper than those sold in stores. This is a fairly strong argument for the owners who are determined, who have decided to improve the landscape of the garden plot on their own. However, to do this is not so difficult as it seems at first: it is enough for a couple of free evenings, a small amount of money for the purchase of materials and desire.

Before starting work, it is necessary to determine the model of the future swing, with the material from which the supports will be made, as well as with the version of the seat. This article presents the swing drawings of pipes with a wooden base. The frame for the seats can be anything - from a carelessly wrapped warm blanket to tailored to the size of soft cushions of dense fabric. It is assumed that these swings will be installed inside the gazebo, and therefore they do not have a roof.

Selection of materials for the manufacture of swings

Metal swings must withstand heavy loads, and therefore preference should be given to reliable and durable materials. So, the children's swing, capable of withstanding up to 200 kg, is made of profile thick-walled pipes with a section of 40x40 mm and a thickness of 1 mm.

To produce a swing from a profile pipe capable of withstanding three adults, pipes 7 cm in diameter and 2 mm in thickness will be required. Such pipes will be optimal for the manufacture of supports.

By increasing the diameter of the pipes and their thickness, it is possible to increase the stability of their construction to the loads: the larger the diameter and thickness of the tube, the greater the load it can withstand.

In addition to the pipes, a plywood or a thick board will be needed - to make the seat base. If the unprocessed board is used for the seat, it is pre-treated with a planer. However, the purchase of plywood and boards can also be saved by using old chairs, countertops or doors. In addition to wood, a rigid metal mesh or a base of plastic pipes can be used to make the walls.

In case the swing will stand outside the arbor, it will be necessary to build protection against precipitation and sun. To do this, on four sides of the swing, it will be necessary to bury four pillars, and on them to weld a rectangular base for the roof. As a roof can be used wood, cellular polycarbonate, metal or slate. If desired, the canopy can be attached to the supports holding the swings of the swings.

Necessary tools and materials

Now let's look at how to make a swing from the pipes yourself. First of all, you need to purchase the necessary materials and prepare tools. Select pipes in accordance with the drawings below. Dimensions of the swing can be changed both in length and width, provided that the overall proportions of the structure are maintained and the thickness of the pipes is increased.

List of required materials:

- Two steel pipes with a length of 6 meters of the same diameter.

- Eight metal corners.

- Two steel arcs (for example, from reinforcement) with a diameter of about 15 mm and a length of 25 centimeters.

- Two wooden canvases (even old window shutters, doors, countertops, chairs, etc.) can come up.

- Two cuts from a furniture cloth (under the size of the basis for a seat).

- Two zippers for making a cushion on the seat.

- A strong rope for mountaineering, capable of withstanding more than 300 kg (or chain).

- Special fastening clamps for repsnura (climbing cord).

- Welding machine.

- A hammer.

- Vice or pliers.

- Pencil or marker.

- Hacksaw for metal or a Bulgarian with a disc for metal.

- Building level.

- Roulette.

- Enamel for painting metal pipes.

This is all you need to make a garden swing with your own hands. From the pipes you can make not only a swing, but a canopy for them, if necessary. In this case, additional pipes and roofing material will be required. You can read about how to make a canopy of pipes and a shower curtain with your own hands.

Also, you should take care of the filling for the seat. In this case, preference should be given to synthetic materials that are resistant to changes in temperature and humidity (for example, sintepon or foam rubber).

Save on the furniture canvas, replacing it with old thick curtains or coverlets. Preference should be given to synthetic breathable or natural cotton materials.

Preparatory work

Before proceeding to the assembly of the swing, cut the pipes to the required length according to the drawing.

Details for the construction of supports

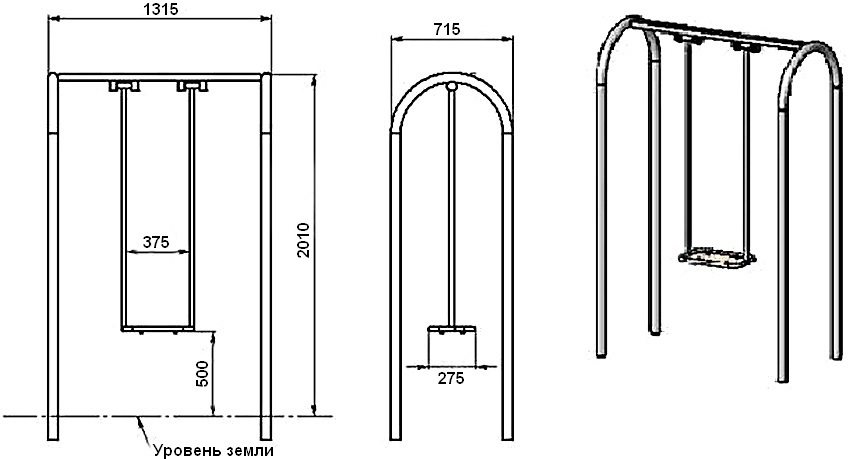

Swings are a construction of a rectangular base of 2 by 1.5 meters and small triangles on two (shorter) sides of this base, connected by a crossbar. On the crossbar there are attachments with a seat. For the construction of supports you need to saw:

- 3 long sections (two - for lower transverse supports and one - for the upper crossbar) to 2 meters;

- 4 medium segments (for vertical inclined supports) of 2.2 meters;

- 2 short segments (for the side parts of the base of the swing) at 1.5 meters - you can do without them.

Details for the construction of a seat

The design of the swing seat is two rectangles connected at an angle of 100 degrees. To make a seat you need:

- 3 metal pieces (for horizontal supports from the top, bottom and center of the seat) 1.6 meters long;

- 3 pieces (for vertical support of the seat back) 0.88 meters long;

- 3 pieces (for vertical supports of the bottom of the seat) length of 0.5 meters.

Mounting parts

The fixtures in these swings are two hinges of reinforcement welded to the upper crossbar. In the hinge, fixing hooks for the climbing cord are inserted, which will hold the garden swings from the profile pipe. Weld the fittings to the crossbar in advance.

Assembling the swing

Before you weld the swing from the pipes, you should prepare the pipes themselves: remove rust from them and take a chamfer at the welding places. When assembling, it is recommended to follow this sequence:

- Measure and mark the welding spots on the corner pieces. In these places, the pipes should be chamfered at an angle of 45 degrees.

- Welding of pipes is carried out according to the planned scheme. The first thing is to build a rectangular base. To do this, two long and two short pieces of metal pipe are simply welded together, forming a classic rectangle.

- Welding details, you should carefully check their location with the help of a building level: to ensure that the angles of inclination of each pipe are met.

- Then, on both sides of the rectangle (along its short sides), vertical supports forming a triangle are fitted.

- Between the vertices of the triangle, a crossbar is installed with the rope (or chain) fasteners fixed to it.

- The foundation is ready. You can proceed with the assembly of the seat. The first thing to do is to weld the bottom of the seat - it is a classic rectangle with sides of 660x1600 mm and an additional stiffener in the middle.

- Then the backrest of the seat is assembled - in the form of an inverted letter S. With the welding machine, the backrest is welded to the bottom at an angle of 100 degrees.

- If desired, the seat can additionally be equipped with handles, holders for drinks, a folding table.

- During the assembly of the seat, provision should be made for the holes for the anchorages.

- The resulting structure is strengthened with metal corners. Metal corners are welded to each corner of the structure: 4 at the corners of the base, 2 - at the top of the triangular supports, 2 - at the top of the day of the seat.

- After welding, all details of the future swing are covered with paint or enamel for metal.

- The connection between the seat and the frame is carried out with a strong strap (or iron chain) and steel hooks. In order for the rope not to "ride" in the hinges, it will be necessary to fasten it with clamps.

- On this the main part of the work is done, the garden swings from the pipes are almost ready. It remains only to prepare a mattress for the swing.

- To make a mattress for a swing, you need to sew 2 large flat cushions 880x1600 mm (for the back) and 500x1600 (for the day) and a thickness of about 10 cm.

- Each of the pillows is desirable to provide lightning - this will avoid problems with cleaning.

- On the perimeter of the pillows, you can sew rope tails - with their help it is convenient to fix the mattress to the base and remove it if necessary.

In the absence of a canopy above the swings, it will be necessary to cover them from rainfall in rainy weather. To do this, a piece of polyethylene film or a cover for the car will fit.

It is assumed that the presented model will be stationary, and therefore its movement from place to place is impossible - it is too heavy. Therefore, the place for the swing should be identified and prepared in advance. It should be level - that the base lay on the ground, adjoining to it on all perimeter.

In some cases (when the surface of the earth is too uneven) it will be necessary to prepare for the swing a concrete or wooden pedestal. Alternatively, the ground under the swing can be leveled, and then reinforced with a plastic base. Install a swing metal from the pipe preferably in the shade - under the tree crowns, in the gazebo or under any other canopy. This will avoid direct sunlight, snow and rain, and therefore prolong the life of the swings.

To visually imagine how to make a garden swing with your own hands from the pipes, you can watch the video instruction.

The swings for the children's playground are metal, unpretentious, resistant to the influence of the external environment (ultraviolet, heat, frost, high humidity, etc.) and can stand outside all year round. All parts and seats are connected to the metal support by means of pipes, chains or reliable ropes, ensuring complete comfort and a sense of security for the swinging. Such a child's swing is inexpensive. This makes them an optimal acquisition for arranging playgrounds in the courtyard of the school, at home or kindergarten, as well as a magnificent decorative element for city parks and parks.

The cost of a metal swing depends not only on the material of construction, but also on the overall dimensions of the product and the number of seats. It can be single, double or triple swings with different forms of support. It is from the form of support, often depends on the safety of the child. Depending on this parameter, the product can be installed:

- on the lawn or soft soil;

- on a hard surface (asphalt or concrete).

You can buy children's metal swings by selecting from our catalog or by contacting the managers of the company on the website indicated on the site.

Catalog view Table view

Catalog of children's metal swings

Today, a lot of companies are engaged in the production of a wide range of playgrounds, sports complexes and versatile swings. Their competition makes children's metal swings more affordable (they can be bought inexpensively by wholesale and retail through our online store). And manufacturers offer domestic buyers not only standard swings painted in yellow, blue or green, but also unique products developed under the guidance of talented designers in the form of cars, cartoon characters and all kinds of animals. Naturally, the price for a street swing in this performance is much higher than traditional analogues for the city (simple metal supports and a normal seat).

In addition to the description, technical characteristics and parameters of each individual product, on the pages of the catalog you can find reviews about the metal swing, written by our customers. Reading reviews, our customers will be able to form their own opinion about the product, the ease and convenience of using the swing, as well as the quality of the product itself. The remaining doubts can always dispel the consultations of our managers.

Metal swings can always be made by hand, with the necessary material and tools. This will significantly save money that would have to spend on ordering a swing or buying a ready-made option. Manufacture of a swing on its own from metal can almost everyone, the main thing is to have patience and get a tool for work.

What do you need to make a swing with your own hands made of metal?

In order to make a swing with your own hands, you need the following tool:- a hacksaw for metal or a bulge for cutting metal pipes;

- metal pipes for the manufacture of carcass;

- keys, bolts, nuts and other connecting elements;

- welding machine for welding the frame with electrodes;

- a container and a concrete solution;

- automotive enamel;

- shovel and tool for drilling holes in the ground.

Create a swing chart with your own hands made of metal.

Thanks to the Internet, the task of making a swing is much simpler. Now you do not need to create a drawing yourself, which is quite difficult. It is much easier and more convenient to find and download a ready drawing, in which, if necessary, you can enter corrections.Making a swing frame with your own hands made of metal.

Having a drawing, material and tools on hand, you can start making a swing. To do this, you first need to cut the required number of pipes. It will take two pipes for the rack, one for the crossbar and four for the base. The length is chosen depending on the wishes and the purpose of the swing.Pipes used in the manufacture of a swing should preferably be thoroughly cleaned from rust and unevenness. This will require sandpaper for metal and a metal brush.

After processing, it is necessary to weld the base, struts and crossbar. This must be done with a welding machine using arc welding technology. To perform this work, the inverter and the third number of electrodes will suffice. After welding, each joint must be checked for strength by hitting several times with a hammer. The quality of welding largely depends on safety, therefore, an experienced welder must perform this work. In order to firmly fix the structure on the ground and make it stationary, you need to excavate pits, install metal rods in them and pour concrete solution. After the solution has solidified, it is possible to weld the main frame of the swing with your own hands from metal to the rods embedded in the ground. Hardening should occur at least a week, so that the solution has gained strength.

The swing seat with your own hands is made of metal.

After the frame is ready to make and install the seat. For the seat, metal tubes of small diameter can be used, with which a frame with backrest and sidewalls is assembled. The basis on which a person will sit is better to make a wooden one.Seat fixing can be different. If the swing is small, it can be hooked to the crossbar using chains on both sides of the seat.

If the swing with your own hands made of metal must withstand a significant weight, then they can be attached to a metal crossbar with the help of pipes or rods.

In order to make the rotation, it is possible to mount bearings rotating on its axis along with the rods holding the swing chair. You can also use a strong rope to hang the chair. For a more comfortable swing, the chair can be made with a footrest by welding a few extra tubes.

Safety swing with your own hands made of metal.

It is important to take care of safety by making all the fastening elements durable and easy to use. If a small child will swing, then on the armchair it is possible to provide the holding belts, not allowing the baby to fall out of the seat during the swing. Backrest and sidewall of the swing chair with your own hands made of metal can be sewn with soft material to make it comfortable.

After the swing is fully installed and fixed it needs to be painted. This will give it an attractive appearance and protect it from external influences. If holes are left on the pipes, it is necessary to select plugs for them so that water does not get inside and they do not rust.

There are a lot of options for the construction of a swing with your own hands made of metal. Everyone who wants to do it can come up with his own design that is different from the others or simply copy by ready-made blueprints.