The company "Teploognezashita SK" performs work on professional maintenance of the required level of fire safety in buildings and structures, including works to achieve the required limit of fire resistance of metal and metal structures.

Company "Teplogonezaschita SK" Having a vast experience of work performs design and installation of fire protection of metal, fire protection of metal structures of any complexity. Our specialists are able, like and want to work! We work with leading manufacturers!

When constructing an object, especially when it comes to places where people come, it is necessary to comply with building codes and regulations. First of all, these norms apply to works related to fire safety of buildings and structures.

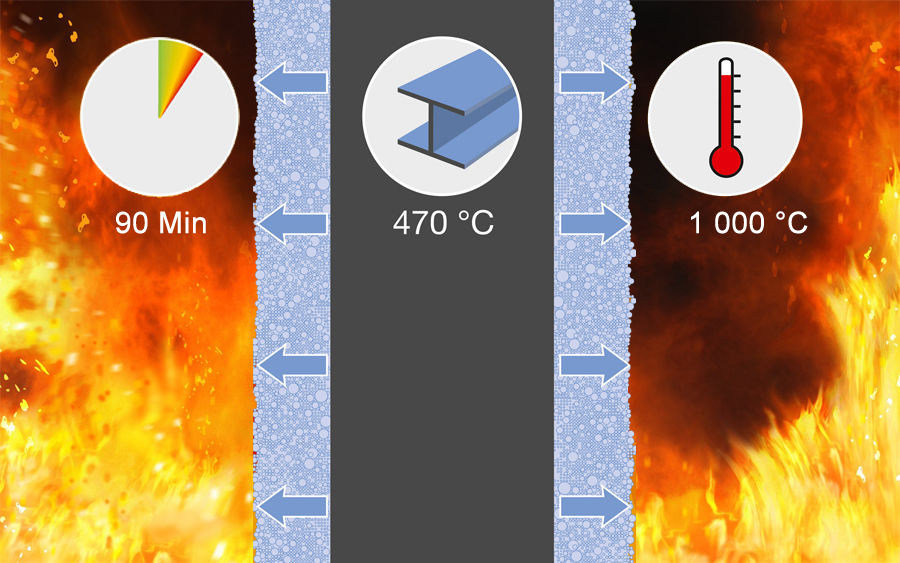

Everyone knows that when interacting with fire, metal has the property of deforming, losing its strength properties, which leads to a weakening of the entire structure of the structure, down to its collapse. The critical temperature at which the loss of load-bearing capacity of steel structures occurs is 500 ° C.

The maximum fire resistance indicates the onset of signs of critical fire damage:

- R - Loss of load capacity

- E - Loss of integrity

- I - Loss of heat-insulating capacity

Depending on the fire hazard, the structures are divided into 4 classes, according to which the requirements for the degree of fire resistance of the metal are established.

When designing a building on the basis of their number of storeys, the length of fire breaks, the designation of the building, the designers indicate the degree of fire resistance of the building. Based on this degree of fire resistance, the fire resistance limit of metal structures is assigned. To determine the required layer of fire retardant coating, it is required to find out the thickness of the metal, and from the thickness it is determined which method of fire protection of metal the designer will choose when designing the flame retardant of the metal.

What regulates the performance of works on fire protection of metal?

Technical regulations on fire safety requirements (as amended on July 13, 2015), in particular:

Article 57. Fire resistance and fire hazard of buildings and structures

In buildings and structures, basic building structures with fire resistance limits and fire hazard classes corresponding to the required degree of fire resistance of buildings, structures and the class of their constructive fire hazard should be used.

The required degree of fire resistance of buildings, structures and the class of their constructive fire hazard are established by regulatory documents on fire safety.

Article 58. Fire resistance and fire hazard of building structures

Fire resistance and fire hazard class of building structures should be provided due to their design solutions, the use of appropriate building materials, as well as the use of fire protection.

The required limits of fire resistance of building structures, selected depending on the degree of fire resistance of buildings and structures, are given in Table 21 of the annex to this Federal Law.

Fire protection of metal structures

The required fire resistance of metal structures can be achieved by:

1. Using thin-layer intumescent coatings, however it is necessary to keep in mind that in accordance with the requirements of SP 2.13130.2012 "Fire protection systems. Provision of fire resistance of protection facilities ":clause 5.4.3. In buildings I and II degrees of fire resistance to provide the required fire resistance of the building's structural elements responsible for its overall stability and geometric unchangeability in a fire, constructive fire protection should be used.

The use of thin-layer flame retardant coatings for steel structures that are load-bearing elements of buildings of I and II degrees of fire resistance is allowed for structures with reduced metal thickness in accordance with GOST R 53295 of at least 5.8 mm.

In accordance with paragraph 3.3 of SP 2.13130, any (including intumescent) coatings with a thickness of more than 3 mm do not belong to thin-layer coatings, therefore, they can be used in buildings of all degrees of fire resistance, regardless of the reduced thickness of the metal.

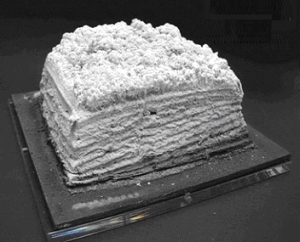

The composition of the fire retardant paint is designed to form a porous, heat-insulating layer during the fire action, which will prevent the metal from heating up to the degree of breaking of the bearing properties, which in regulatory documents is 500 degrees Celsius in testing. In simple words, a sponge forms on the surface of the metal when heated, which will not allow the metal to heat up, it will protect it from destruction for a given time, which is indicated by the designer when designing the building. The compositions of fire retardant paints are quite diverse, mainly water or a solvent, in which an "intumescent composition", thickeners, plasticizers, and other chemical components are added which, in various combinations, make it possible to achieve the required level of absorption and dissolution of temperature in a certain period.

Fire-retardant paints can be increased tens of times in thickness by exposure to high temperatures.

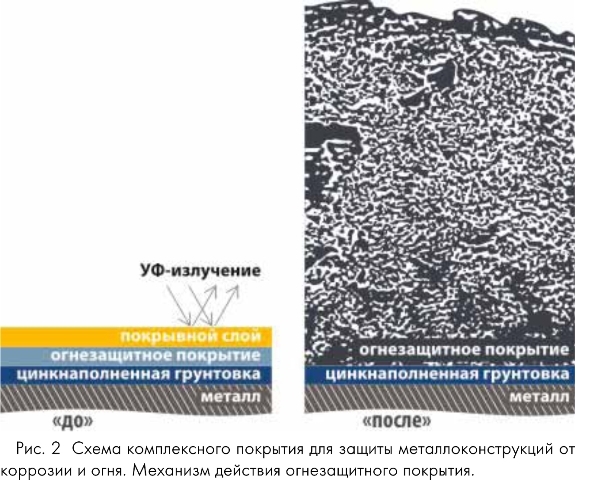

Any fire retardant paint is usually applied to the appropriate primer. When operating structures in an environment of aggressive environment, the coating composition is applied to the surface of the fire retardant coating.

2. Use of constructive fire protection for metal structures.

In accordance with GOST R 53295-2009 (with the change No. 1):

p.3.6 constructive fire protection. The method of fire protection of building structures, based on the creation on the heated surface of the construction of a heat-insulating layer of fire-protective equipment. The constructive fire protection includes thick-layer sprayed compounds, plasters, facing with plate, sheet and other fireproof materials, including on the frame, with air interlayers, as well as a combination of these materials, including thin-layer intumescent coatings.

The use of constructive fire protection of metal is advantageous in that the cost of materials used is moderate, but at the same time the fire resistance of the structures to be protected is considerably high, as well as resistance to external aggressive factors.

Fire protection of steel structures with slabs is the most effective method of fire protection. In composition, they are quite diverse, their physical properties are divided into hard and soft. The materials used in their manufacture are characterized by low thermal conductivity and high heat resistance.

Fire protection of metal plates can be provided in one or more layers, which depends on the required fire resistance limit. Fire protection plates - more labor-intensive process than the previous two methods of fire protection, especially for buildings of complex configuration and shape. But the lining of the structures can be carried out in cold weather, which is an indisputable plus.

3. Use of technological solutions. For example, irrigation of structures in case of fire with water.

In the practice of building buildings and structures for fire protection of premises are widely used automatic water extinguishing systems АУПТ design and installation which we also perform

Currently, these facilities are mainly used only to suppress fires and ensure non-propagation of combustion. Their work is not taken into account when determining the limits of fire resistance of building structures.

However, on a par with its main purpose, water extinguishing installations can be used purposefully and efficiently and are often used to increase the fire resistance of metal structures. The practice of such use of AUPT is available both in our country and abroad. However, the use of such a method of increasing the fire resistance of metal structures requires special justification and coordination with the territorial fire protection authorities.

When using the deluge fire extinguishing system (sprinkler) for these purposes, which operates over the entire protected area, the fire resistance limits of the structures can be increased to the required for all building designs, regardless of the specific place of the fire, and the conditions of exposure to high temperatures on the structure.

Equipment of the same room sprinkler installation of fire extinguishing (irrigation) involves maintaining the load-carrying capacity of structures in a period of time equal to the required fire resistance limit, and only those structures that are exposed to high temperatures.

The conditions for the operation of AAPT (temperature 70 ° C) provide an early start time of the sprinklers, in relation to the time of the onset of critical heating of the building structures and. It is obvious that the limits of fire resistance of building structures will be determined by the operating time of the fire extinguishing (irrigation) installation, i.e. the time when cooling water enters the structure.

For the premises of the production building and the warehouse of liquid raw materials, in contrast to the previously discussed methods of raising the fire resistance limits of building structures (see Section 6), the fire protection of constructions by water irrigation is quite reliable and does not contradict the conditions of operation of premises (possible increased humidity).

The expediency of fire protection of constructions by water irrigation is also conditioned by the possibility of organizing the protection of all structures without exception (columns, beams, trusses, ties, braces, etc.). including small cross-section, without using other methods of fire protection, as well as the possibility of using the AUPT to extinguish the fire at an early stage of its occurrence.

The company Fire Protection recommends that you do not save on fire protection, understand the importance of these measures and make the fire protection of metal structures of your building as accurate and qualitative as possible in order to protect yourself, your partners, customers, material values, and the whole building.

To find the ideal option for fire protection of metal you will always help the experienced specialists of the company "Teploognezashita SK".

Also we can offer fire protection of other materials: concrete building structures , fabrics , of wooden constructions , cable lines , cable penetrations , air ducts etc. To protect yourself from troubles and accidents with us will become much easier.

We will help to create all the necessary conditions for your safety and avoid the huge losses that can lead to careless handling of fire or non-compliance with simple fire safety rules.

Calculation of the cost of fire protection of metal structures per m2:

Cost of works on fire protection building structures can be evaluated in two ways:

- on the basis of estimated costs with the application of an appropriate regulatory framework, and this is the only true way for construction of facilities with the involvement of budgetary funds,

- on the basis of labor costs, overheads and profits laid by the installation organization at commercial construction sites.

Regardless of the method of fire protection, price for fire protection work consists of 2 components:

- cost of material, taking into account its delivery to the facility

- cost of installation works (price for work)

Calculation of the cost of fireproof material for metal structures.

Let's take a real example: The processing of the load-bearing element of a building made of I-20K2.

The design has its own fire resistance limit, which is equal to R7 (about 7 minutes) - this is not enough to fulfill the requirements of FZ-123 for a building of the 3rd degree of fire resistance (for example).

In FZ-123 it is stipulated that the fire resistance limit of load-bearing structures of a building of the third degree of fire resistance must be at least R45. In accordance with the technological regulations of the manufacturer of fire retardant coatings to achieve R45 metal structures with a reduced thickness of 5.37 mm, it is required to apply 0.85 kg (for example) of fireproof material per 1 m2 at a dry layer thickness of 0.52 mm (for example).

Calculate the area heated by the fire surface of metal structures.

Knowing the required flow rate and the surface area of the heated surface, it is easy to determine the required theoretical consumption of fire retardant composition. Practical differs from the theoretical taking into account the loss of material during its application. Losses can reach from 10 to 30% and depend on the method of application, the weather conditions in the performance of work, the qualifications of the performers.

Knowing that 1kg of fireproof material costs 300 rubles (for example), multiply the practical consumption of the composition at its price. The cost of fireproof material is 0.85 * 300 = 255 rubles m2

Calculation of the cost of installation work on the fire protection device for metal structures.

This calculation takes into account:

- the level of qualification of workers, their production in the performance of fireproof work,

- the average salary of workers in the organization,

- taxes levied on wage workers,

- established in the organization the norm of overheads and profits

- costs associated with the delivery of workers to the facility and their accommodation

- costs associated with the use of lifting gear and machinery

- taxes levied on the organization in accordance with the current legislation of the Russian Federation

- And etc.

In order to calculate the cost of fire protection work, let's take the above-mentioned surface area of the supporting element of the building from the 20K2 double-bar to which, as we have already found out, it is required to apply a 0.52mm layer. Knowing that the first pass must be at least 0.2mm and subsequent to 0.5mm, we assume that the application of this layer will take place in 2 passes. Suppose that the cost of one pass costs 100 rubles per m2, of course, it depends on the amount of work. The price for the work of fire protection of the metalwork of the structural element of the building made of IK 20K2 will cost 200 rubles m2 - this price is exemplary, and depends on many unknowns.

As a result, the fire protection of metal structures price per m2 with this material will be equal to 255 + 200 = 455 rubles / m2

Working on the market for many years, we know how to achieve the required fire resistance of building structures for minimal money, analyzing the cost of all certified fire protection solutions on the market. We will select the most cost-effective method of fire protection based on the specific operating conditions of buildings and structures.

You just need to tell us the degree of fire resistance of the building, as well as the requirements prescribed in the STU for its design, if any.

Active fire protection systems

Fire-retardant paint for metal structures is one of the means used in the implementation of a complex of fire-fighting measures. And if in the home such compounds are rarely used, then when designing industrial buildings and structures, the use of fire protection is one of the mandatory conditions.

In this article we will talk about how these paints work, and also give some tips on how to use them.

Use of fireproofing

Principles of fire protection

When we talk about protecting a building from a fire, we first of all mean the prevention of the ignition of materials and the limitation of the spread of fire. And from this point of view the processing of metal structures looks, naturally, not very logical: indeed, steel does not burn, so there is nothing to be afraid of.

In fact, this approach is fundamentally wrong, and that's why:

- First, in the event of a fire, all metal parts heat up quickly enough to accelerate the spread of the fire. Simply put, a red-hot beam can bring fire to where the open flame does not reach.

- Secondly, when the metal is heated to approximately 500 ° C, the metal structure loses its carrying capacity. In the vast majority of cases, this leads to the fact that the building collapses.

Thus, protecting the metal from fire, we reduce the scale of the fire, and also increase the time for the evacuation of personnel and material values. It is for this reason that any instruction in the industrial construction industry contains recommendations for the thermal protection of steel trusses, beams, etc ..

Several methods are used for this:

- Lining of steel elements with non-flammable plates (withstand an open flame for up to three hours).

- Finishing mixtures (2 hours)

- Painting metal structures with flame retardant paint (provides up to an hour and a half protection).

The first two technologies, of course, are more reliable, but the price of materials used and the laboriousness of the processes are quite high. That's why in most cases they prefer to use the painting technique.

Characteristics of paints

The flame retardant paint for metal fulfills one function: upon ignition it does not allow the temperature of the substrate to rise to critical limits.

In more detail, the protection mechanism looks like this:

- In a normal state, the coating is inert and does not react with environmental factors.

- Once the painted surface begins to heat up, the protective composition decomposes. At the same time, a so-called coke layer is formed over the metal, keeping its temperature at an acceptable level.

- During the decomposition of the paint, gases are released that slow down the combustion process, as well as water. All this contributes to hardening the coke layer and preserving the integrity of the structure.

It should also be noted that compositions of this type can be either non-expanding or intumescent:

- The non-expanding composition forms a thin heat-insulating film of high density on iron beams. Despite its characteristics, such protection quickly burns out, because this type of paint is used less and less.

- If there is a choice, then preference should be given to funds based on potassium silicate (liquid glass). The thing is that the sodium-silicate paints, when they get wet on them, form white stains on the surface - they are high.

- Intumescent formulations act on a different principle: when heated, the volume of the paint layer increases to 70 times. In this case, the thickness of the heat-insulating layer increases accordingly, which allows the metal to resist heating for more than 1.5 hours without deformation and loss of strength.

- Intumescent compositions include flame retardant paints for metal Polystyl, Krauz, Proterm Styl and the like.

Note!

The increase in volume, and therefore the effectiveness of coloring, depends on the type of material.

This information can be found on the manufacturer's website or on the packaging.

Method of application

Requirements for composition

Paints used to solve such problems must meet a number of requirements:

- First, the tool used must comply with fire safety regulations.

Note!

Restorative and anticorrosive compounds, such as Zinga conductive paint, are not classified as flame retardant.

- Secondly, it is desirable that the coating served at least 15-20 years, otherwise permanent updates will be too expensive.

- Thirdly, it is very important that after drying out of the paint all toxins evaporate, and later metal construction was safe for humans and animals.

- Also one of the parameters on which to choose is the resistance to vibration. Since the structure is operated under industrial loads, the paint should not peel off.

- It's also a good idea to choose the formulations that allow tinting: this will give the machined details a more attractive appearance.

As for the features of specific brands, they must be chosen depending on the tasks assigned. For example, many products are designed exclusively for indoor use, while other colors (which, naturally, are more expensive) can be used outdoors without loss of performance.

Method of deposition on metal

The technology of applying flame retardant pigments to metal structures by hands assumes the following sequence of operations:

- All steel parts are cleaned from rust and sanded. For this purpose it is convenient to use grinding machines with metal rigid brushes.

- After stripping remove chips and rust, and then - we process metal structures with primers. The type of soil should be consistent with the composition used, but the most commonly used are insulation anticorrosive primers.

Note!

Many manufacturers specify, what means is better to cover a basis before drawing a paint of this or that stamp.

It is worth listening to these recommendations.

- The primer should be dried thoroughly. Only after complete drying can a protective mixture be applied. (See also the article.)

- Before applying the paint, mix thoroughly. Since the amount of packaging for such a tool is quite large, it is better to use a mixer attachment.

- Painting can be done both with the use of spray guns, and manually. In the first case, the material consumption and labor intensity of the process are reduced.

Advice!

As a rule, these paints are applied by a layer, the thickness of which does not exceed 1 - 1.2 mm.

This is due to the fact that with an application thickness of more than 1.5 mm, swelling is uneven, which can lead to rupture of the thermal insulation layer.

Conclusion

If properly selected and used, the metal fire retardant paint can minimize the damage caused by the fire. Of course, it is desirable that you bought it in vain, but it is better to think in advance about the unpleasant consequences. The video in this article contains additional information on this topic, so before you buy and start working it is worth exploring it.

The modern construction industry is inconceivable without metal. And if in one-story building it often plays an auxiliary role, then the high-rise buildings are mainly composed of metal, concrete and glass. With the development of civilization, buildings are becoming larger and higher, and the metal in them is growing more and more. Metal is the foundation of modern buildings. Therefore, every year, the requirements for the protection of metal structures from various impacts, including fire, are growing. Yes, the metal does not burn, but loses strength when heated to 500 0 C. And the loss of strength of even one key node can lead to collapse of the entire building. For this reason, the requirements for the fire protection of metal structures are so high today. One of the progressive methods of fire protection of metal structures is the coating of the metal surface with flame retardant paints. Work with these materials has its own technological features, which we will discuss in this article.

Main differences fire retardant paints from the usual consist in the fact that they are applied in several layers, resulting in a coating thickness of up to several millimeters. Besides, fire retardant materials , in view of its complex composition, have worse adhesion than conventional household paints and enamels. Also, the correct technology of applying flame retardant materials with the normalized drying time of layers is very important.

The application of flame retardant materials can be divided into four stages:

1. Surface preparation

2. Application of soil

3. Application of paint

4. Application of a protective coating

Surface preparation

Preparation of metal surfaces for fire retardant treatment is of the utmost importance. With improper preparation, the coating under external or internal influence can collapse and all work will go wrong. In practice, there is a wide variety of states of the metal surface before painting. Even for non-used metal structures, state standards define four surface states.

GOST 9.402 and ISO 8501 classify the metal surfaces to be cleaned according to the oxidation state as follows:

A - The surface of the metal is almost completely covered with a rolled-up mill scale adhering to the metal. There is almost no rust on the surface.

B - The surface of the metal began to rust, the rolling scale began to peel off from it.

C - The surface of the metal with which, as a result of corrosion, the rolling scale has disappeared almost completely, or with which the rolling scale can be easily removed. On the surface of the metal, small corrosion lesions are observed.

D - The surface of the metal, with which, as a result of corrosion, the rolling mill scale disappeared and on which corrosion on the whole surface is observed.

In addition, there may be different types of pollution on the surface of the metal, soil or paint of unknown chemical composition, etc.

In any case, for the application of flame retardant materials, thorough cleaning of the metal surface is necessary. Preparation of metal structures for the application of fire retardant paint is made in accordance with the requirements of SNiP 2.03.11-85 "Protection of building structures against corrosion". Metal structures should be prepared for application of an anticorrosive primer coating, in accordance with the requirements of GOST 9.402-80 "Preparation of metal surfaces before painting", according to the degree 2.

In practice, two methods of cleaning are used - chemical and mechanical. In the process of chemical cleaning, rust converters, old paint removers, etc. are used. Mechanical cleaning can be manual and mechanized. Mechanical cleaning is carried out with an abrasive tool, with crushing, sandblasting. The main task of cleaning is to get a clean metal surface without any coatings on it. Another obligatory stage of surface preparation is degreasing, which is carried out with the help of various organic solvents. The purpose of degreasing is to remove organic and inorganic fats and oils from the surface of the metal. Degreasing operation is carried out immediately before the application of the first coating layer and is often combined with dust removal (removal of dust from the metal surface).

Application of soil

The first layer when applying any fire retardant coatings is always the primer. The most commonly used acrylic primer GF-021, as the most universal. The tasks of the primer are anticorrosion protection of the metal and good adhesion to the metal and subsequent layers of the coating. It is necessary to approach very carefully to the choice of the soil used for flame retardant treatment. In the market there is a huge number of soils, manufactured not according to GOST, but according to technical specifications. Soils on oil-polymer varnishes produced according to the specification have a softening point of 90-100 0 С, while the temperature at which the fire-protective coating starts to work is 220-250 0 С. As a result, under fire, the ground loses its properties, which can cause its deformation and peeling together with the fireproof coating. In addition, the use of cheap analogs produced by TU leads to an increased drying time of the soil, a decrease or loss of adhesion of the fire retardant coating. It is also very important to withstand the soil until completely dry before applying fire retardant paint , otherwise it may be subsequent cracking of the fire retardant coating. The application of flame retardant materials to old coatings, or on the surface primed (painted) with paint and varnish materials not recommended by manufacturers of fire retardant paints, can lead to deterioration of adhesion, swelling, or peeling of the fire retardant coating.

Paint application

Fireproof paint or lacquer must be applied in full compliance with the manufacturer's instructions, clearly maintaining the recommended intervals for drying the layers and the thickness of the applied coatings. In case of violation of the application technology, the fireproof coating can be destroyed during operation. Reducing the drying time leads to the fact that the previous layer, which has not gained strength, can not withstand the weight of the subsequent layer and loses its adhesion, or becomes cracked. A large number of solvent vapors emerging from a low layer lead to swelling of the next layer. Increasing the thickness of the layers also leads to an excess of the strength of the previous layers and to cracking.

Fireproof varnishes are applied by brush, roller or airless spraying in 2-4 layers. When applying varnish by airless spraying it is possible to dilute it with a solvent. The airless spray parameters are shown in the table.

|

Options |

Values |

|

Diameter of nozzle of atomizer, mm |

0,42-1,60 |

|

Spray angle, degrees |

20-40 |

|

Diameter of the supply hose, mm |

10 |

|

Length of the supply hose, m |

Max 60 |

During the work, the air temperature should be at least -20 ° C, relative air humidity not more than 80%.

Interlayer drying with different methods of application should be at least 1 hour (for laminated surfaces - at least 2 hours) at a temperature of + 20 ° C and a relative air humidity of not more than 80%. Before applying the subsequent layer, it is necessary to make sure that the varnish on the surface is completely dry before tearing. The application of lacquer by brush or roller increases the drying time by 20-25%. At lower temperatures and higher humidity, the drying time also increases.

Fire retardant paints subdivided into the colors of summer and winter use. Summer has a water-dispersible base and, if necessary, can be diluted with water. Winter paints have an organic basis and are dissolved by a solvent or white spirit.

During the application of summer fire retardant paints, the air temperature should be at least + 5 ° C, relative air humidity not more than 80%. The temperature of the steel surface must be above the dew point by 2 ° C.

The paint is applied by brush, roller, by airless spraying.

|

Options |

Values |

|

Working pressure, atm, atm |

60 |

|

0,88 (0,035) -1,2 (0,047) |

|

|

Spray angle, degrees |

10-30 |

|

Diameter of the supply hose, mm |

10 |

|

Length of the supply hose, m |

Max 60 |

When applying the first layer of paint, the thickness of the wet film should not exceed 0.3 mm.

When applying subsequent layers, the thickness of the wet film should not exceed 0.8 mm in one layer.

If it is necessary to obtain a greater thickness of dry coating, the paint is applied in several layers.

Interlayer drying with different methods of application should be at least 3 hours at a temperature of + 20 ° C and a relative humidity of not more than 80%. Before applying the next layer, it is necessary to make sure that the paint on the surface has dried to the touch.

The application of paint with a brush or roller increases the drying time by 20-25%. At an air temperature below +20 ° C and a relative humidity above 80%, the drying time of the paint increases.

High humidity and low temperature can cause condensation of moisture on metal surfaces, which slows the drying out of the paint and can lead to deterioration of the adhesion of the paint to the surface to be painted.

Application of winter fire retardant paint is carried out at a temperature not lower than -25 ° C, relative humidity of air no more than 80%. The temperature of the steel surface must be above the dew point by 2 ° C.

For the application of paint by airless spraying, it is recommended to use equipment with the following parameters:

|

Options |

Values |

|

Working pressure, atm, atm |

100 |

|

Diameter of the spray gun nozzle, mm (in) |

0,88 (0,035) -1,04 (0,041) |

|

Spray angle, degrees |

10-30 |

|

Diameter of the supply hose, mm |

10 |

|

Length of the supply hose, m |

Max 60 |

When applying the first and subsequent layers, the thickness of the wet film should not exceed 1.0 mm in one layer.

To obtain a greater thickness of the dry coating, the paint is applied in several layers.

When painting complex configurations, it is advisable to reduce the thickness of the applied "wet" layer (less than 1.0 mm). Otherwise, excessive accumulation of paint in the inner corners is possible, followed by cracking of the coating upon drying.

Interlayer drying with different methods of application should be no less than 4 hours at a temperature of + 20 ° C and a relative humidity of not more than 80%. Before applying the next layer, it is necessary to make sure that the paint on the surface has dried to the touch.

The application of paint by brush or roller increases the drying time by 20-30%. If the air temperature is below + 20 ° C, the paint drying time is doubled for every 100 ° C.

Protective Coatings

Fire-retardant paints, for the most part, are not weatherproof, as they are intended for indoor use. Therefore, when operating in conditions of the presence of corrosive media, high humidity, the possibility of splashes, temperature differences need to be protected. As a protection for fire retardant coatings, varnishes or paints are resistant to weathering. for example

When operating a fire retardant coating in conditions of high humidity (above 80%), temperature difference, and also in the presence of aggressive media, an additional protective coating must be applied to the surface of the fireproof coating. For example, lacquers KO, coatings based on cholesterol, HB, EP or other waterproofing compounds.

Under long-term exposure to high temperatures, non-flame-resistant structures are susceptible to deformation and fracture. The application of fire protection on the metal structure ensures an increase in the fire resistance of metal structures to the required values, and also limits the limit of fire propagation along the elements of buildings.

Several methods for creating thermal insulation coatings on the surfaces of metal structures have been developed:

Plastering with cement-sand mortar, heat-insulating compounds, which include: liquid glass, cement, perlite sand, gypsum;

- Installation of heat absorbing screens and materials: granulated mineral fiber, gypsum plasterboard coatings, liquid glass, asbestos-cement slabs;

- Application of fire protection for metal structures by spraying special fire retardant intumescent paints that, under the influence of high temperatures, form a heat-insulating porous layer;

- Constructive solution of fire protection.

The cost of applying fire protection on metal structures is ambiguous and depends on many factors that are taken into account in specially developed projects where calculation of fire protection of metal structures.

We, the Alpsfera company, provide a wide range of services that ensure the application of fire protection to metal structures by various methods.

Fire-fighting treatment with intumescent paints is made by high-class professionals with application of painting equipment and materials of the highest quality from the best foreign manufacturers. The experience of our employees allows us to find the most effective methods of conducting work, adjusting the intensity of the paint supply and finding the optimum spraying angle of the composition. Taking into account each of these factors, uniform application of fire protection on metal structures is achieved.

Constructive fire protection of metal structures includes the following types of fire treatment of metal structures:

Concreting (fire resistance< 2 ч.) - Обкладка кирпичом (огнестойкость< 2 ч.) - Оштукатуривание (огнестойкость > 2 hours)

- Facing with fireproof sheets and plates

- Fireproof suspended ceilings

Such coatings are durable and reliable fire protection, but they are quite laborious and significantly increase the mass of structures. However, the use of light plaster solutions (vermiculite, perlite) not only makes it easier to apply fire retardant to metal structures, but because of the low density they have low thermal conductivity, and therefore have a fire resistance of up to 4 hours.

After the production of all fireproof works at the site, the fire inspector checks the quality inspector, who signs an act for the fire protection of metal structures, and then representatives of the Ministry of Emergency Measures, which carry out a final check of all the work done and the documents compiled, and then leave their resolution on the act of accomplished work.

The price is set for the application of fire protection, taking into account the material consumption and all work on fire protection of metal structures. Our company provides high-quality services at affordable prices:

|

More on the topic:

|

We offer services for applying flame retardants to metal and other structures. Order fire retardant treatment on our website. Please contact our specialists for professional free advice.

The cost of applying fire protection from 80 rubles / m2

Fire retardant treatment is the coating with special paints and compositions of metal structures, to increase the stability of structures when exposed to extreme high temperatures, for example, in fires.

Types of processed objects:

- dyeing of farms

- panels

- steel frameworks

- reinforcing nets in workshops of factories and plants

- residential buildings

- masts and supports of transmission lines

- towers, antennas

- tower and gantry cranes

- tanks, tanks

- and painting of other types of metal structures

Why do they apply fire protection?

The objectives of applying fire protection are as follows. All types of fire retardants are designed to protect and increase the fire resistance limit, stability and design strength of steel structures from 90 minutes or more.

Additional properties of such products are effective protection of metal from corrosion.

Fire-retardant treatment is an obligatory and most effective method of preserving the functionality of load-bearing structures when exposed to high temperatures. Bearing metal structures, handled correctly selected composition, perform well their functions even in the conditions of long fire.

How the protective properties of fire retardant paints / compounds work

The properties of fire retardant paints are activated when the ambient temperature rises. Under the influence of high temperature, the applied protective mixture is significantly foamed (swelling), creating a thermo-insulating cushion and thereby providing thermal protection to the painted structure. While maintaining its strength and all the bearing properties.

Some fire retardant paint compounds can be used for the processing of metal structures located inside the premises. For example, in places like shopping centers, malls, airports, railway stations, residential and non-residential, public and industrial premises, as well as outdoors and under a canopy.

Modern fire-fighting mixtures emit inert gases into the ambient air, which reduce combustion, temperature or completely suppress the burning of fire.

Selection of a fire retardant for the forthcoming treatment should be handled by a certified specialist.

Types of fire retardants

Depending on the type of fire-retardant coating, mixtures can be in the form of:

- solutions for impregnation

- special paints, varnishes

- fire retardant pastes and coatings

- mixtures of different fire retardants, including a combination of several substances

According to the operating conditions, fire-retardant mixtures / compositions are intended:

- for use in heated dry rooms

- for non-residential premises with high humidity

- for the processing of external (street) structures

- for special operating conditions

Depending on the processing method, the fire-retardant means are divided into:

- combined formulations

- specialized compounds

- fire retardants

- coatings

- impregnation

Fire protection of apartment houses

We all know that it is quite difficult to stop a fire. It is much easier to prevent its appearance. Our company, which includes only professionals - climbers, is engaged in fire retardant work.

During the construction of residential houses, metal structures have recently become increasingly used. At the moment, under modern construction conditions, their erection is an integral part. They are durable and reliable, but it is very important to comply with all fire safety requirements.

It is extremely important to increase the fire resistance of buildings

Why is it so important to coat metal with flame retardant paints? The fact is that in the event of fire, the metal becomes very plastic, therefore its deformation occurs, with every minute its strength deteriorates and becomes weaker. But, if you cover metal structures with flame retardants, then protect the metal from fire. But if it does happen, then effective fire protection will greatly improve the state of affairs, securing people with possible evacuation and retaining the walls from collapse. It can be said that the application of fire protection is an important necessity.

Our experienced specialists perfectly know and in practice mastered all the rules for applying fire retardant paints. It is worth noting that the process of applying fire protection is time-consuming and difficult.

Our advantages

We offer you affordable price, fast deadlines, compliance with legal requirements and a decent level of quality of the work performed!

Additional Information

The choice of the type of composition or mixture of formulations depends on the type of material for which fire protection is intended.

Fire-retardant drugs are divided into several basic large groups:

- mixtures for application on metal structures

- for coating or impregnating power and non-electric power cables

- for processing structures of wood or materials based on it (fiberboard / particle board and other materials)

- for polymeric materials of different groups and for different purposes

- for fabric materials, carpets, upholstery, nonwovens and other textile materials

Fire-retardant preparations are made on the basis of an aqueous polymer dispersion.