Not only serves as a reliable support for the home, but also creates its aesthetic appearance. After all, the material has a color palette of the most different. Therefore, today the demand for this roofing is growing rapidly. Many wonder what should be the structure of the roof of corrugated. In our article we will answer this and many other questions.

The article material will be useful to you, even if you do not plan to carry out roofing work in the near future. But the technology of roofing from corrugated board will be known - then you can easily evaluate the work of the roofer.

We carry out the preparation for roofing

It is important to think carefully about everything.

The first step is to carry out the preparatory stage:

The estimate for the roof requires consideration of the following factors:

- conditions of work performance (independent or through roofing intermediaries);

- the size and design of the roof;

- used material.

The construction market provides consumers with a large range of corrugated flooring. This allows you to purchase material according to your tastes and preferences. The professional flooring varies in color, brand, thickness and height of sheets. As a rule, profile sheets are fixed on a wooden base - a truss system.

The main feature of the preparatory stage is the transportation of the material. Pay special attention to this moment. After all, if everything goes smoothly - then the professional flooring will have the maximum characteristics available. Otherwise, the roofing of the profiled sheet will give you a lot of trouble and frustration.

Tip: To cover the roof, you can use profiled sheets marked C.

The device of a shed roof of corrugated

The material is quite popular in the construction environment. He bribes his price and reliability. As a rule, it is recommended to use profiled sheets on slopes of a roof 12 meters long. At the same time the slope of the roof should be at least 8 degrees.

The material is used for roofs with two slopes or a slope of more than 15 degrees. The installation of the roof depends on the angle of the slope. It can be overlapped with one or two corrugations.

The angle of inclination also affects the type of sheathing device:

We put waterproofing

Before conducting assembly workshould be implemented. Lay the layer on the truss structure. It will protect the roof from moisture. The next step is to create crates. After that it will be possible to stack the profiled material.

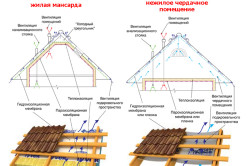

When conducting waterproofing of the roof of corrugated board, you must consider the type of roof:

Caution: When using film, remember that one side of it contains markings from the manufacturer. This side should be on top when laying the material. Do not overturn the film - in order not to lose its basic properties.

We put a heater

Give it to special attention to warming of a roof from a professional flooring. Waterproofing and heat insulation contribute to the formation of so-called, under the sheets of the profile.

When laying insulation for the roof - should take into account the type of roof. When installing a warm roof should be used slab and matte insulation. You can not leave a gap between the layers of heat and. The process of laying two materials is made between the rafters.

Carrying out the device of overlapping from a professional flooring of a cold roof - it is necessary to create the ventilated space. To reduce condensation, apply a layer of vapor barrier material to the insulation.

The roofing of roofs by a professional sheet, despite the price of the work and the fairly wide variety of other roofing materials presented by the construction market, has a high level of popularity among owners of private houses and industrial buildings and structures. There are a number of objective reasons for choosing this material that we will now deal with with you.

What is a professional sheet

Profiled roofing sheet, or otherwise called profiled, is made of several types of sheet thickness from 0.55 to 1.1 mm.mm.

Most often manufacturers use thin-rolled products:

Most often manufacturers use thin-rolled products:

- Hot Dip Galvanized (14918)

- Covered with zinc by electrolytic method (TU 14-1-4695-89)

- With a covering from alyumotsinka (TU 14-11-247-88)

- With aluminosilicon coating (TU 14-11-236-88)

Additionally, special paintwork and polymer coating can be applied to the professional flooring, which performs protective and decorative functions. Materials for such coatings use polyester and PVDF paints, pural and others. The texture of the coating can be matte or glossy with a very wide variation of the color solution.

The profile configuration usually has a trapezoidal or wavy shape, which is attached to the sheet on special bending mills. It is profiling at times that increases the bearing capacity and rigidity of the product and makes it attractive for use as a reliable roofing material from a technical point of view.

Professional flooring coatings significantly improve its performance and increase service life, as well as provide more wide opportunities for color matching for design purposes.

As a roofing material we are interested in roofing sheeting. Note that it differs from the wall in height and width of the profile - stiffeners have a range of sizes from 20 to 44 mm.mm.

It should be noted that the professional sheet is used not only for the roof, but also to create fences, gates, gates, etc. can be installed in a short time with minimal cost.

It should be noted that the professional sheet is used not only for the roof, but also to create fences, gates, gates, etc. can be installed in a short time with minimal cost.

You can also build a gate from a professional sheet with your own hands and decorate them decorative elements. considered the process of manufacturing and installation of the gate.

Preparation for the device of a roof from a professional flooring

Without mentioning now the topic of the device of the power structure of the roof, let us dwell only on the organization of work.

Without mentioning now the topic of the device of the power structure of the roof, let us dwell only on the organization of work.

At the first stage, you need to decide on the amount of corrugated board and additional completing materials you need. For this you need a project or at least a calculation of the material.

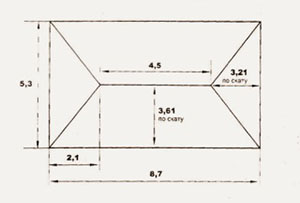

The calculation process (in the absence of project documentation and a resource statement for roofing materials) is preceded by the measurement of the slope, diagonals and the roof sheathing.

Measuring finished design the roof is necessary even if there are drawings in the project, since the actual dimensions may have drawing errors that are important to consider. It is also necessary to remember that the length of the slope is not a parameter sufficient to calculate the area of the material to be chosen - the roofing sheeting of the first (lower) row should protrude beyond the eaves of at least forty millimeters.

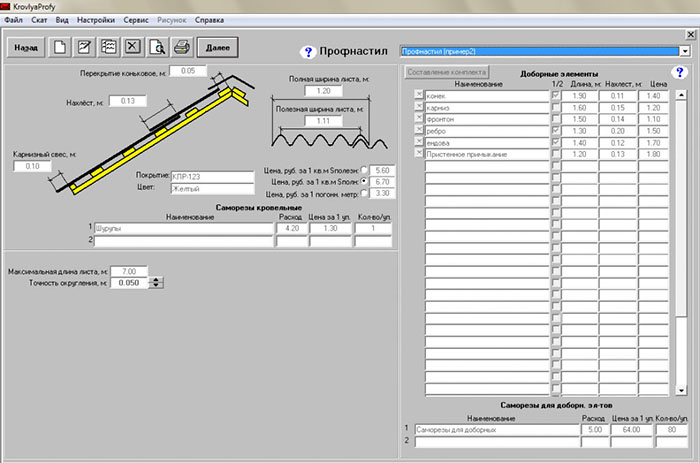

Calculation of roofing on the roof in the program

How to buy professional flooring

Now a few words about the purchase, transportation and storage. It is recommended to give preference to wholesale suppliers or warehouses. This will allow you to purchase material cheaper. Also, some traders provide independent delivery of material to your construction site with their own transport.

Now a few words about the purchase, transportation and storage. It is recommended to give preference to wholesale suppliers or warehouses. This will allow you to purchase material cheaper. Also, some traders provide independent delivery of material to your construction site with their own transport.

And another significant factor relating to the choice of supplier. It is desirable to buy additional materials (cornices, wind strips, etc.) complete with corrugated flooring from one manufacturer. By this you guarantee full compliance with the properties of materials and their colors.

It is no secret that, despite the use of standardized color tables, different manufacturers may have different colors of final products. Of course, it is more profitable from the financial side.

Approximate prices for professional sheet

Warehousing of a professional leaf and preparation for the roof device

As for warehousing at the construction site, it should be remembered that profiled should be stored in a horizontal position. Despite its relatively high lateral stiffness, storing sheets vertically (especially large packs) can lead to sheets sagging and additional troubles during installation. It should be remembered that the base of the storage area must be level.

As for warehousing at the construction site, it should be remembered that profiled should be stored in a horizontal position. Despite its relatively high lateral stiffness, storing sheets vertically (especially large packs) can lead to sheets sagging and additional troubles during installation. It should be remembered that the base of the storage area must be level.

When preparing for the roof of the roof with a professional sheet, the instruction requires that there be a sloping lag from the ground to the edge of the roof to facilitate sheet lifting. Such a decision and all the above storage tips will additionally contribute to ensuring not only the ease of installation, but also the preservation of the attractive appearance of the profiled sheets and the preservation of their coverage.

The best option for laying corrugated flooring professionals recommend ordering complete cover of the entire height of the slope from one of the edges. In this case, the sheets climb to the roof on the uncovered roof, and this is an additional guarantee of the safety of sheets already laid from damage. If this is not possible, stacking from the edges along the length of the slope in rows is used as an option.

In any of the options, each row must be completed with an overlap of a subsequent row of not less than 200 mm (taking into account the width of the sheet profile, this size may vary). Gaps should be sealed with special bitumen or polymer mastics.

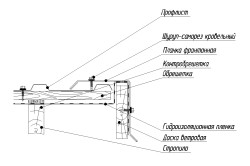

The step is not recommended to do more than forty centimeters. Waterproofing roll materials are used in the roof structure, and slats with a height of 10-25 mm should be pierced over them with the same pitch (40 cm). They are needed to ensure the passage of air between the sheets of corrugated and waterproofing for ventilation of the roof.

In recent years, using corrugated roofing to overlap roofs has become much more common - according to some information, among newly built houses such a roof can boast 5 times. more buildingsthan 10 years ago. This is not surprising: an inexpensive and externally attractive, profiled sheet is light and therefore easy to install and transport. In addition, the construction technology of the roof of corrugated is relatively simple and includes the following main steps:

- taking measurements and calculating the need for materials necessary for the performance of work;

- waterproofing installation;

- ventilation device and installation of lathing;

- laying on the roof of the profiled sheet;

- installation of end slats and junctions, as well as skate, snow holders and valleys.

Below we briefly describe each of these stages.

The calculation of the need for materials for the roof of corrugated

From the correct calculation of the amount necessary materials depends on the duration of roofing and transport costs.

The basis for this calculation is the area of the roof slopes. The easiest way to determine the number of profiled sheets for a simple shed or gable roof with rectangular ramps. Having calculated the area of the slopes, we divide it by the area of the sheet of corrugated sheet and get the number of sheets. It is only necessary not to forget that in the area of the slopes it is necessary to take into account cornice and gable overhangs.

If the length of sheets of corrugated board does not allow closing the roof in one row, the technology of roof covering with profiled sheeting provides for an overlap between the rows of the coating, the size of 100-200 mm. The size of the overlap depends on the angle of the roof. The amount of overlap is also added to the coverage area.

The calculation of a broken roof of a complex shape is somewhat more complicated, but it is performed according to the same principle. For this, the entire roof surface is conventionally divided into several simple geometric shapes, for each of which the area is calculated separately. For sections of the roof in the form of a triangle, it is better to think over the layout of the covering sheets in advance, this will reduce the amount of waste of roofing material.

When counting the number of profiled sheets, one should not forget about the need to purchase all the additional elements, especially since the technology of roof covering with a professional flooring involves installing some of them before laying the profiled sheet. These elements include curtain strips and lower end strips.

Installation of roofing waterproofing

Roofing technology with corrugated roofing provides for mandatory laying under the roofing layer of film waterproofing. It protects the covering space from atmospheric moisture, for various reasons, fell under the roof covering. But the main task of the under-roof waterproofing is to drain the condensate formed on the inner surface of the roofing corrugated floor with sudden changes in the outside air temperature.

If attic insulated, the role of waterproofing can perform a special diffusion membrane. The peculiarity of this material is that, being a reliable barrier to atmospheric moisture and condensate, the membrane freely lets out water vapor contained in the air of the attic room.

The device of ventilation of the roof and lathing for fixing the profiled sheet

The roofing technology of the professional sheet provides an obligatory device under the roof covering of a special ventilation gap. The air stream constantly circulating in it, directed from the eaves to the ridge of the roof, removes excessively humid air from under the roof. This excess moisture can result in wooden structures kontrabetki and obreshetki fungus and mold, which is the cause of a significant reduction in the service life of the roof covering.

Arrange the ventilation gap by mounting along the rafters of wooden bars, section 40 × 40 or 50 × 50 mm. After installation of the counterbribe, a batten is installed across the rafters. Her step depends on the slope of the roof and the carrying capacity of the professional sheet. Perform crate out wooden beam or boards, section 100 × 30 mm.

During installation, you need to remember about the need to strengthen the crates in the places of passage through the roof of the flue and ventilation channels, as well as in the places of fastening of the ridge and installation of snow guard.

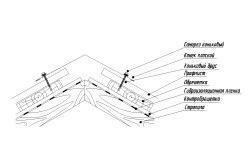

Roofing technology profiled

After the installation of the batten, install the curtain rail and the bottom (bottom) rails of the valley. Endovo is called the joint of the roof slopes, forming an internal angle. When installing broken mansard roof, reliability and integrity of the valley must be paid special attention. After all, it is in this place that the water from rain and melting snow from the surface of both slopes flows.

After installation, the end boxes start laying the roofing sheets. Roofing technology profiled provides first installation of the first corrugated sheet from the corner in the bottom row (when laying the coating in several rows). Then with an overlap on the lower one, the first sheet of the next row is placed, and so on.

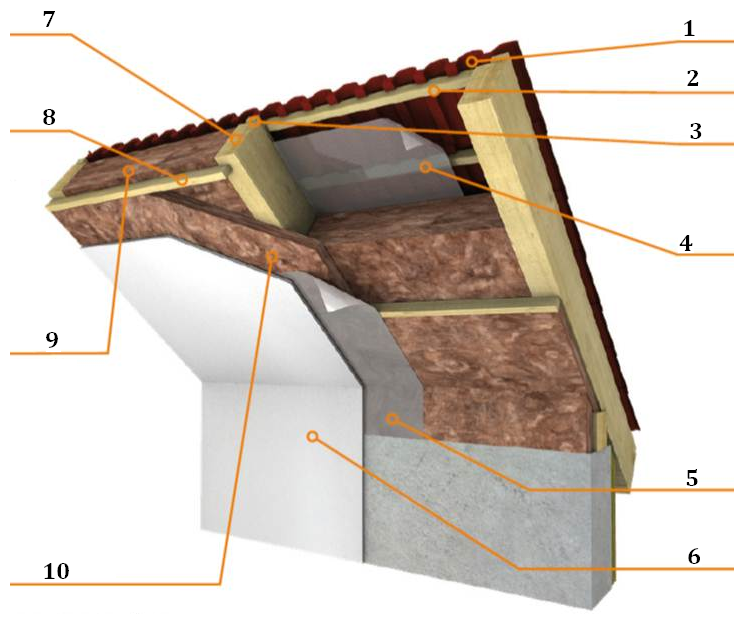

Roof technology of corrugated roofing and the structure of the roofing pie:

1. Professional flooring. 2. Crate. 3. Kontrobreshetka.

4. Waterproofing membrane. 5. Vapor barrier.

6. Interior finish. 7. Rafters.

8. Crate for interior decoration.

9. The layer of roofing insulation.

10. An additional layer of insulation for walls.

Coating sheets are initially attached temporarily. Permanent fastening is performed after laying at least several sheets in each row and aligning them along the eaves and gable overhang.

Attach a profiled sheet to the crate with special roofing screws. Screw them into the lower wave of corrugated board, so roofing screws must have a gasket made of special neoprene self vulcanizing rubber. The heads of the screws are painted in the color of corrugated board and completely invisible on the roofing.

It is recommended to install a special profile seal on the cornice eaves and skate under the covering of corrugated flooring. At the place of attachment of the ridge, the compactor must fill the coating profile by no more than 2/3. This is necessary so that the air from the ventilation gap can freely go outside.

Installation of additional elements of roofing

After laying and fixing the profiled sheeting, a ridge, wind slats on the gable overhang, upper valises of the valleys and slats are installed on the roof.

The installation of the ridge elements begin on the leeward side. They are mounted with an overlap of 100-150 mm on each other and fastened with long screws through the upper wave of the corrugated flooring.

Wind strip it is installed along the edge of the gable overhang and protects the coating sheets from being blown up by strong wind gusts. Upper end panels perform a purely decorative function, closing the edges of the corrugated board at the junction of the two slopes of the roof.

In modern construction uses a huge amount different materials, which combine a high level of quality with operational characteristics, as well as functionality and efficiency. The presence of a complete set of these advantages is one of the main requirements for modern building materials, which can be safely attributed to professional flooring. It is widely applicable as facing material. And the roofing of the corrugated, made in compliance with all technological processes will create a practical and durable roof.

The main characteristics of the material

What are the characteristics are inherent in such material as a professional flooring? First of all, it is a method of its production. For its manufacture is used galvanized steel sheet, which is used for cold rolling. A special coating that prevents corrosion is applied on both sides to the profile - wave or trapezoid. Such a coating may have different shades.

Depending on the destination, distinguish profiled: bearing, wall and roofing. Any of these groups of material has its own wave height, metal thickness and designation.

For roofing work, you should choose a professional flooring with the letter designation "H" or "NA". The latter, by the way, is a versatile material and can be used as a wall variant.

Roofing of corrugated roofing involves the use of corrugated flooring, which has a height of at least thirty-five millimeters. If the roof has a small length of the slope, then there is the possibility of using corrugated and with a lower wave height.

Use of roofing material

The technology of roofing of corrugated roof according to SNIP involves the use of corrugated, having a height of forty-four millimeters. Roofing profiles have an aluminum or zinc coating with an additional polymer layer that plays a decorative or protective role.

The base for corrugated flooring can be wooden bars or metal girders. Load bearing capacity The base depends on the strength of the wind inherent in this climatic zone and the expected load of roofing material on the roof of the building. In addition, in order to adjoin the profiled sheet to the wall system, the roofing of corrugated roofing provides for the presence of aprons, made of galvanized steel sheets and coated with a polymer layer.

Finishing of roofing passes is carried out with the help of shaped roofing elements having a comb similar to the transverse sectional section. In addition to the eaves, gutters and ridges, other elements are used in the construction of the roofing structure: special plugs, snow barriers and ridge seals.

Profile sheets can be used both for cold roofing in the form of piece elements, and as part of a warm multi-layer roofing with a solid sheet.

The basic rules for the installation of roofing sheeting

Laying profiled sheets should be carried out with strict observance of certain rules. First of all, it is full safety and following the installation technology in the process of lifting the material and subsequent movements on the roof, as well as attaching the base material.

Raising the flooring on the roof is carried out with the help of a lag by two workers, a third person takes it upstairs. At the same time, no more than one sheet is lifted at a time.

If there is a strong wind outside, work on raising the profiled sheeting should be postponed for a while!

To move on the roof should wear shoes with soft soles and walk on it is necessary, trying to tread in the deflection between the waves. To do this, lay the flooring in such a way that the deflection tightly adjoins the grid. Since the edge of the material is sharp enough, to ensure your own safety, work must be done with rubber gloves.

Laying of professional sheets is overlapped. The size of the overlap depends on the angle of the roof. The lower it is, the more overlap. For a flat surface, the technology for laying material is somewhat different. In this case, the sheets need to be applied in two corrugations to prevent moisture from entering under the roof covering.

The chips, which are formed when attaching professional sheets with self-cutting screws from their screwing in, should be necessarily removed with a brush. Otherwise, the rust that forms on it over time will significantly ruin the roof.

If products with a protective film are used, then it must be removed during installation in order to avoid its “accretion” with the polymer material.

Roofing pie - will keep heat and protect from noise

Using a roofing sheeting for the roof of your house, it is very important to create good warm and sound insulation, since more than 20% of the heat the house "gives" to the environment through the roof. And a special heat-insulating layer that performs a protective function, referred to as a roofing cake, does an excellent job with this task.

What is the roofing cake for corrugated board? The first layer on the counter grill mounted on top truss systeminsulation is laid down.

Please note that the slope of the roof of corrugated should be at least 20%.

The next component of the roofing cake is a waterproofing layer. It is necessary to ensure that water does not flow through the joints of the sheets and at the junction points. On top of the waterproofing with observance of all ventilation gaps, a crate is installed for the profiled sheet, which is laid on it with the last layer.

All layers of the cake are interconnected and perform a specific functional task. An error in the technology of at least one layer can lead to a decrease in the performance characteristics of the entire roof and its operational life. The following situations may indicate that the roofing pie was assembled incorrectly:

- Ceiling leakage;

- Heat loss;

- Condensation;

- Come on.

In the event that high-quality thermal insulation installation work has been carried out, it can guarantee minimum heat loss through the roof covering and prevent surface condensation.

Installation of a special wind barrier made of vapor-proof material roll type will help to avoid blowing the roof.

The compactor performs two main functions. Firstly, it limits the heating of the roof space. And, secondly, it creates a good sound insulation in the room. The vapor barrier layer solves the issue of moisture from the room in the roofing pie. And the waterproofing “filling” of the cake protects the insulation from the penetration of condensate into it, which usually forms along the bottom of the profiled sheets.

When laying a waterproofing film, it is necessary to observe the distance between the rafters, on which it lays no more than 120 centimeters.

Crate for profiled sheets

The lathing is an obligatory element in the roofing of the profiled sheet. For single roofs wood battens of the following sizes are used as a batten: 5x5 cm, 3x10 cm, or 3x7 cm. The batten’s elements are laid out in 25 cm increments. the boards. Crate for gable roofing is mounted in increments of 50 cm.

For roofs that have a complex geometric shape, you should not close the crate tightly in the gutters and valley, you must leave a gap for ventilation of 5 cm. The bottom end of the valley is set along the crate, the upper part of which is folded over the nails. The roofing of the corrugated imposes the requirement that the bottom plate had an entry under the profiled sheet at a distance of 25 cm.

If the roof structure is ventilated or chimneys, will require the installation of additional crates.

Fastening sheets together is an important stage of the roofing process.

Special attention in the construction of the roof of corrugated board should be paid to the fastening of the sheets with each other. After all, roofing nodes from a professional sheet are the most important point in this work. A careless attitude to the nodes located at the junction of the sheets can significantly affect the performance of the future roof for the worse. The process of laying sheets does not cause difficulties, much more time and effort is spent on the places of their joints.

The main purpose of the roof knots of corrugated flooring is to create insulation transitions of the horizontal surface to the vertical and, of course, in the connection of professional sheets among themselves. Therefore, their implementation should be approached with great care.

When creating junction points, the following actions are performed:

- To prevent ingress of dust and moisture in the place of junction, a strip is installed, under which the seal is arranged;

- A wall is created in the wall, which is inserted into the groove and then fixed with dowels and coated with a layer of sealant;

- The strap is connected to the profile by a self-tapping screw, which is screwed into the most prominent point of the wave.

Registration of the ridge of a roof from a professional leaf

The roofing of the corrugated also implies the presence of the ridge, the design of which occurs during the final stages of installation.

Laying of ridge elements is also made with an overlap of 200 mm. With the help of screws, they are attached to the upper corrugation. Self-tapping screws should be chosen, taking into account the height of the professional sheet wave. And the step that you need to adhere to when attaching is 300 mm.

If the roof has a slight slope, then the use of the seal will be relevant. Thanks to him, it is possible to eliminate the ingress of moisture in the case of oblique direction of precipitation. Between the ridge and the seal, the right decision is to leave a small ventilation gap.

It is most expedient to begin the installation of the ridge from the side of the roof less exposed to rain.

The importance of competent installation

The service life of the roof of the house can be maximized if the roofing of the corrugated board is made according to all the rules of competent fixing sheets and factors such as are taken into account:

- possible wind effect;

- probability of high temperature expansion in the center of the sheet;

- sufficient density at the connecting points of the professional sheets.

Compliance with the process of fastening material to all existing standards is achieved by using certain sizes of screws for each type of work. For example, the connection with the crate should be provided by 4.8x35 mm self-tapping screws, but the mount of the ridge will not do without longer self-tapping screws - from 80 mm.

Simplicity of repair of a roof from a professional flooring

One of the obvious advantages of such a roofing material such as profiled is the speed and simplicity of its installation and dismantling. Therefore, when repairing the roof from a professional sheet, there are no particular difficulties.

In most cases, roof repair can be limited to removing one or more sheets that are unsuitable for further use and replacing them with new ones. If the damage is insignificant, then replacing the sheets may not be necessary - in this case it will suffice to put in patches.

Choosing roofing material for the roof of your house, you should pay special attention to the flooring. After all, this is not only a convenient option for installation and further operation, it is also a material with an attractive appearance and affordable price.

- Beautiful design of the nodes of the roof and wall of the building

Profiled sheet (profiles) the best way to establish itself in the form of material for the roof because of its functionality and low prices. Thus, the roof of the profiled metal sheets is a fairly acceptable solution even for a beginner who has decided to cope with this difficult task on his own. Professional sheets are coatings sufficiently resistant to any mechanical and atmospheric influences, are quite practical, durable and have an aesthetically pleasing appearance. Of course, the numerous advantages of the material are not in themselves a basis for considering the issue of its mandatory use in roofing, however the best material for quick installation and long functioning of the roof can not be found. Moreover, even on the right to prepare and strengthen the nodes of the roof of the profiled sheet, it does not require too much special effort. Taking into account the need to ensure a reliable connection between the components of this building material, it should be understood that in this process special attention should be given to roofing units made of corrugated flooring.

Features of a roof from a professional leaf

Before embarking on the roofing of this roofing material, it is necessary to consider its main characteristics and ways of organizing the junction of the roof. So, the main advantages of a corrugated roof are:

- high load capacity with relatively low weight of the sheets;

- corrosion resistance;

- long term quality coverage service;

- relatively simple installation of the main types of profiled sheet, which are offered in the construction market.

Photo 1. Pediment knot.

They are sheets with a wave height of 8 to 44 mm, with a trapezoidal or sinusoidal profile shape. Often used for the construction of the roof lightweight profile sheets with a wave height of 35 and 44 mm. As the roofing material is actively used and the wall profile, frame, the wave height of which varies from 57 to 114 mm, which adds additional rigidity to it.

Before proceeding with the laying of roofing sheets, builders should take care of the acquisition of the necessary tools in the work:

- hacksaws;

- hex head screwdrivers or drills;

- screws or screws;

- waterproofing material;

- directly professional sheet;

- preparation for work on installation of a roof from a professional flooring.

Before you purchase the necessary construction material, experts advise to prepare a platform on which it will be possible to arrange the imported sheets.

After all, they in no case should not be deformed. Otherwise, it will be almost impossible to achieve a reliable junction of the roof to the roof rafters. Think about the process of feeding sheets to the roof in advance, such devices as winches are most often used, or lumber rails can be installed. Most often, builders use logs.

Back to table of contents

The main points of contiguity of the material

Photo 2. Plank end of the node.

Roofing material is laid on a truss-covered system of trusses, which is created from bars, with a section of 50x50 mm, with a step chosen according to the size of the profiled sheet used. Roof insulation is usually carried out using thermal profiles and gaskets made of thermal insulation materials. Waterproofing of the roof will require waterproof coatings, for example, special membranes or hydrophobic films.

When laying the roof, special attention should be paid to places where several sheets are joined, or to those parts of the roof where it is adjacent to the wall of the building. These points are called nodes, and if during installation you treat them carelessly, then in the future, such roofs are unlikely to reliably protect the building and the people living or just inside it from adverse influences from outside. Sheets themselves are very easy to fit, because they are lightweight and do not require special skills from builders. But the nodes of the roof of galvanized iron are a rather difficult moment. Therefore, although roofing works quickly, joints take the most time.

It is especially important to properly cope with the places of transition of sheet material of the roof from the horizontal to the vertical plane. This assembly is performed according to the following scenario: a bar is installed at the place of junction, which will protect the roof from moisture and dust getting inside, before that a sealant is installed under the bar. At the level where the plank fits to the wall in which it will be necessary to make a strobe, and install it in the groove. After that, with the help of dowels, attach the bar and sealant to handle all places of junction. It is advised to connect the bar with a profile using screws, which are screwed into the most prominent point of the wave.

Back to table of contents

The main knots from a professional leaf and the materials necessary for their correct processing

Photo 3. Scheme of the prince.

There are several types of roofing nodes. These are pediment, and end, and eaves, and ridge knots. Plus, the junction of the junction to the wall.

The gable knot (photo №1) is arranged with the help of the following tools and materials:

- Professional sheets.

- Screws - roofing screws.

- Gable strap.

- Waterproofing film.

- Wind board

The nodal elements of the gable are mounted on a wooden frame, which must necessarily be treated with an antiseptic solution. Then lay a waterproofing layer, which is necessary to ensure ventilation and to protect the frame from condensation. A layer of insulation is laid on top of the waterproofing layer. Then proceed to the lining of the frame bars. They need to be installed in increments of up to 40 cm. And only after that the whole gable can be covered with professional flooring. Fasten the sheets with screws, which should be screwed into the sheet bend using an electric drill. Between the sheets fasten screws with rivets.

Photo 4. Proper organization of the ridge knot.

Under the end of the end node (photo No. 2), dense flooring is made of edged boards, at the level of the existing crates, receding a distance of 60 cm from both sides of the groove. Then install bottom strips endov, overlapping not less than 20 cm. When constructing the joints of flat roofs, it is necessary to use sealing mastic. Attach the lower bar first with the edges with nails, and full reinforcement should be done simultaneously with the final installation of the entire roof.

High-quality device ridge knot.

One of the most difficult and important points of coverage gable roof is an proper organization ridge knot (photo №4). At the same time, ridge strips should be laid so that the overlap is not less than 10 cm. Fastening sheets of professional sheets to the crate are made with roofing screws, which are recommended to be installed after about 30 cm.

Installing the junction bar.

The length of the junction is most often equal to 2 meters. Lay these slats with an overlap of 20 cm. In those places where the slat will be joined to the profile sheets, it should be reinforced with self-tapping screws. A suitable step should be equal to 40 cm. The site of attachment of this plank to the wall can be hidden under the decorative covering.