The oil industry is the main branch of industry and economy of the Russian Federation. Annually in the country millions tons of black gold are extracted. To extract combustible minerals from the bowels of the Earth, special devices are used to pump oil, fuel oil, oil products, formation fluid with compounds, and also to reduce the content of hydrocarbons and water. Such mechanisms are called oil pumps. They provide reliability and safety of actions, and also regulate the efficiency of pumping.

There are the following types of pumps for oil:

- screw;

- diaphragmatic;

- hydropower;

- the mainline;

- multiphase;

- lamellar;

- jet;

- rod-type;

- rod screw.

Screw Pumps for Oil Production suitable for the mechanical production of heavy fuel. Such units are widely used in industry, especially for pumping viscous liquids. With the help of this device it is possible to extract viscous oil together with sand.

This kind of oil pump has several advantages:

- ability to pump heavy viscous fuel;

- pumping a lot of sand;

- resistance to significant amounts of free gases;

- powerful anti-abrasion protection;

- small coefficient of emulsion formation;

- relative cheapness;

- compactness of the ground mechanism.

Typically, screw pumps consist of compressor pipes, rod string, drive, transmission system and power source, gas separators and so on.

These devices are designed for pumping liquids, gases and vapors, including connections. Such work is carried out when transporting a viscous liquid along the rods of the screws. This creates a closed space that does not allow the fuel to move in the opposite direction.

Hydraulic piston pumps for oil production are designed for pumping out formation fluid from wells. Such units are used for extraction from deep openings of oil products, which do not contain mechanical connections.

These devices consist of: a downhole pump, an immersion engine, a channel for lifting fuel and water, a surface power mechanism, and a working fluid preparation system. During production, oil is released to the surface of the well along with this liquid.

Such pumps have several advantages:

- possibility to significantly change the main characteristics;

- ease of use;

- possibility to easily carry out underground repairs;

- use in directional wells.

Diaphragm pumps for oil production are a kind of volumetric type devices. The basis of such a mechanism is the diaphragm, which protects the extracted matter from getting to other parts of the pump. This unit consists of a column on which oil moves, a pressure valve, an axial channel, a helical spring, a cylinder, a piston, a support, an electric cable, and so on.

Such pumps are used in oilfields where oil production contains mechanical connections. The advantages of this device are the ease of installation and use.

Plate-type pump for oil production consists of a housing with a lid, a drive shaft with bearings and a working kit, the elements of which are distribution discs, stator, rotor and plates.

Let's list the main distinguishing characteristics of this device:

- good reliability and durability;

- high efficiency of oil production;

- excellent operational properties;

- resistance to wear of parts.

Jet Pump for Oil Production is a modern and promising device for the oil industry. It is able to bring the technology of using deposits to a new higher level. Such a mechanism consists of a channel for supplying working fluid, an active nozzle, an intake channel for the injected liquid, a displacement chamber and a diffuser.

Today, jet pumps are widely used due to their simple design, the absence of moving elements, high strength and reliable operation even in extreme situations, for example, with a high content of mechanical compounds and free gases in the produced liquid, increased air temperature and aggressiveness of the products.

Jet pump systems provide:

- stable operation of the mechanism;

- free regulation of bottomhole pressure;

- maintenance of the optimal functioning of the device with uncontrolled changes in such factors as water cut, pressure in the formation, etc .;

- facilitated and rapid inflow of oil and withdrawal of the deepening to an optimized procedure after its suspension;

- effective use of released free gases;

- prevention of fountain opening on annular areas;

- rapid cooling of submersible motors;

- stability of the current load of the device;

- increasing the efficiency of the extractor.

All these characteristics distinguish the jet pump among other mechanisms and make it the most popular in various industries. Such an installation makes it possible to extract oil in the best quality and in the shortest possible time.

Rod pumps for oil production refer to devices of volume type. They are used to lift liquid from the depressions under the influence of pressure, which creates this mechanism.

Such a pump consists of cylinders, valves, plungers, fasteners, adapters, rods and so on. This type of mechanism is used in more than half of the existing oil fields.

The wide use of sucker rod pumps is due to their excellent qualities and characteristics:

- high operating efficiency factor;

- ease and simplicity of repair;

- the possibility of using different drives;

- the possibility of their installation, even in extreme situations: with a high content of mechanical compounds, increased formation of gases, pumping out corrosive fluid.

Rotary screw pump for oil production is often used for mechanized extraction of heavy fuel, drawing and grinding fluids. Such pumps also have their advantages. Among them: an affordable price, the lack of insulated gas and so on.

Trunk Pumps for Oil Pumping are used to move fuel products along the main, technical and auxiliary pipelines. Such installations provide a high pressure head for the transmission of transported liquids. Their distinctive characteristics are: reliability, economy of operation.

Multiphase pump for oil transfer consists of two main elements: the body and rotors. The use of such installations will help:

- reduce the load at the opening of the opening;

- reduce the number of technical equipment;

- efficient use of released gases;

- it is profitable to exploit remote deposits.

This variety of pumps is used for pumping petroleum products through the main pipeline.

Exhibition "Neftegaz"

Exhibition "Neftegaz" This is a large-scale event not only for Russia, but also for other countries. The exposition helps to bring new domestic and foreign companies to the oil and gas market, as well as to increase competition among already well-known companies.

This year the event will be held traditionally in the territory of the Central Exhibition Complex "Expocenter". The business program of the exhibition is quite diverse. It includes conferences, presentations, master classes, seminars, discussions and other events. Visitors will have the opportunity to conclude successful deals, see innovative achievements in science and technology, and learn about new companies in the oil and gas industry.

Page 1

Oil pumps (Table 26.6) are designed for pumping oil, petroleum products, liquefied hydrocarbon gases and other liquids that are similar to those indicated for physical properties (density, viscosity, etc.) and corrosive effects on the material of pump parts.

Oil pumps have mechanical seals. All parts of the mechanical seals are made of stainless materials, the pair of friction sliding surfaces made of high-alloy chrome steel and graphite. Despite the high circumferential velocity on the slip surface (and 25 m / s), the seals meet the operating conditions. The shafts, made of high-quality steel, are protected by bushings of chrome steel. Labyrinth throttle bushings located between the throat of the pump and the end seal are made of stainless material. The pump housing has an axial connector. This makes it possible to easily get inside the pump when the lid is removed. Bearing housings are also made detachable, which allows to extract the pump rotor without dismantling the supply and pressure pipelines.

Oil pumps, nor giving fuel to injectors in engines ND-22 and ND-40-2, are structurally different from each other.

The main oil pumps and electric motors to them on the BKNS are installed under general cover. They are installed separately from pumps, behind a gas-tight wall, in a manner analogous to that of traditional pumping. Supply fans that serve to create excess pressure in the room of electric motors and supply fresh air to the pump room are located in a separate block-box of retaining and supply air fans. Exhaust fans that remove contaminated air from the pumping room are located outside the end of the room of pumps and motors with a common shelter. Heating of the rooms of pumps and electric motors is carried out by electric heaters of 160 kW capacity, installed in the block-box of retaining fans. The supply of heated air from the air heaters is carried out by the fans of boost and supply of fresh air.

Oil pumps of standard sizes QG 300/2/100 and NG 300/450/100 have identical bearings and bearing housings. For the operation in the open air bearing housings are made in closed version. Thus, the pump is completely isolated from the environment. The advantage is that both sizes can be equipped with the same electric motors. The described pump designs can easily be provided with spare parts. These pumps perfectly passed the test at the Druzhba oil pipeline. Of the 4,500 km of the pipeline route, approximately 3000 km are equipped with pumps produced by the GDR. The pumps have shown themselves well under adverse operating conditions.

For oil pumps, they must only be used with explosion-proof electric motors. It is allowed to use electric motors in the usual design with their installation in a separate room through a partition wall.

The main pumping oil pumps have 1600 kW electric motors type ATD-1600, purged, with a closed ventilation cycle, equipped with two air coolers installed in the upper part of the stator housing. Cooling medium for air is water circulating through the pipes. Water and air move countercurrent. The necessary air circulation in the motor housing is created by a special fan.

When designing oil pumps, special attention should be paid to methods for reducing gap leakage, since most oil pumps are low specific speed pumps for which leakage trays are a sensitive factor.

Details of oil pump seals should be made of materials that do not provide pricing.

The given series of oil pumps is used for pumping liquids in the temperature range from -80 to 400 ° C.

A distinctive feature of oil pumps is the use of mechanical end seals, pumps usually provide the ability to replace the end seals gland. In hot pumps there are chambers for intensive cooling of seals. To increase the suction capacity, the impeller of the first stage is made with a two-sided inlet.

Mastering the production of domestic oil pumps from the very beginning was carried out on the basis of parametric series, which establish the minimum number of pump sizes of the same purpose that are necessary to cover a given range of values of feeds and heads. The production of oil pumps is small in nature, the largest annual output of pumps of the same brand does not exceed 150-200 pcs. Most pumps were produced within 5 to 10 years without significant modernization and needed a moral update. In addition, 15 to 20 years of experience in the manufacture and operation of a large fleet of pumps in oil refineries has shown that pumps have an excessive variety of designs with a low level of unification of units and parts within the whole range of pumps.

A distinctive feature of special oil pumps is the prevalent distribution of spiral type pumps. In the oil industry, pumps with a heated or cooled casing are widely used.

In the marks of single-stage oil pumps with a two-sided inlet, the number before the letter designation (ND) indicates the diameter of the discharge nozzle in millimeters, reduced by 25 times, and after the hyphen there are prefixes: c-high-pressure; s - medium-pressure; x - chemical; B - petrol; Nm - modernized oil.

It is prohibited to use oil pumps that do not meet the technical requirements for working with temperature and pressure.

Centrifugal - Centrifugal pumps, intended for, petroleum products, liquefied hydrocarbons and liquids, which are similar in physical and chemical properties to oil and petroleum products. Centrifugal can be in a variety of design, with different oil pumping control systems.

Centrifugal differ from other centrifugal pumps, above all, special operating conditions. When processing oil, the nodes and aggregates are affected not only by complex hydrocarbons, but also by factors such as a wide range of temperatures and different pressures. Another peculiarity of oil and oil products processing is the viscosity of the pumped medium, they must provide pumping of oil with a viscosity of up to 2000 cSt.

They are also used in various climatic conditions from low temperatures of the North Sea to high temperatures in the United Arab Emirates and in the deserts of the USA, therefore they are manufactured in various climatic designs.

When pumping oil, processing oil and lifting hydrocarbons from a depth (oil wells), it is necessary to ensure a sufficient level of power. The type of energy used by the equipment can have a significant impact on the performance of the well. Under various conditions of use, it is advisable to select different types of actuators: mechanical, electrical, hydraulic, pneumatic, thermal. The most convenient is the electric drive, which in the presence of power supply provides the greatest range of characteristics of pumping equipment for oil pumping. But in the absence of electricity or limitations on the power of the supplied current, for example, gas turbine engines, internal combustion engines, and for pneumatic actuators, it is possible to use the energy of natural gas of high pressure and even the energy of associated gas, which increases the profitability of the installation.

Proceeding from the foregoing, it is possible to distinguish some constructive features. First of all, the design features of the hydraulic part of the pump unit, special materials that take into account the installation of the pump unit outdoors, a special design of the mechanical seal, explosion-proof electric motors, which are relevant for all types of equipment for oil pumping. with the drive installed on a single foundation plate, between the shaft and the body is installed mechanical seal with a system of washing and supplying the gate fluid. Details of the flow-through part are made of carbon, chromium or nickel-containing steel. It is accepted to divide into three types: cantilever pumps - with an elastic coupling, a rigid clutch, without a coupling, installed horizontally and vertically mounted on paws or along the central axis with a pumped liquid temperature of up to 400 C; two-pump pumps: one or two-stage, multistage single-hull and double-hull, single-sided and double suction for pumping oil and petroleum products with a temperature of more than 200 C; vertical semi-submersible (pendant) pump: single-hull and double-hull, with drain through the column or separate drain, with a guide device or a spiral tap.

Thus, - pumps ensuring safety, reliability, maintainability and energy efficiency of oil and petroleum products processing, pumping.

OIL REFINING

Oil refining and production represents a number of unique solutions for flow control. We offer a wide range of products and services to meet the needs and special requirements of today's refineries.| High-temperature double suction |

|

| High-temperature two-stage Mounted between the bearings, the radially split housing ensures reliable operation of the pump. Fully meets the requirements of API-610. |

|

Vertical semisubmersible pumps for difficult working conditions |

|

|

9th edition API-610, fully matching bilge pump VS4 Model 3171 is a veteran among vertical semi-submersible and process pumps. Thousands of installations in production processes, drainage of sedimentation tanks, corrosive fluids, pollution control, salt melts indicate the excellent performance of the 3171. Easily installed. Widely used for installation on drainage tanks for pumping petroleum products and drainage water mixed with various petroleum products. Also used as emergency pumps. |

|

| |

|

| The ruler of the multistage double-hull technological horizontal model Goulds 7200 (CB) with a radial connector, cone-shaped diffuser, cartridge-type rotor. Goulds 7200 is manufactured according to the standard API-610. |

|

For heavy duty modes:

|

|

Pumps designed for pumping oil and petroleum products are used in oil production processes: during drilling operations, pumping out formation water from wells and injecting formation fluid into the well. These pumps are divided into three groups. Separate types of pumps are used at the stage of pumping oil through field and main oil pipelines.

Drilling pumps are, as a rule, piston and plunger pumps used to inject liquid media (clay, cement, salt solutions). These pumps are used for flushing and cementing of oil and gas wells in the process of drilling and overhauling them, as well as for injecting liquid into the formation to intensify oil production.

Among the piston and plunger pumps, the mud pumps are the most powerful, which determines the way the feed is regulated via the gearbox used in the design of these pumps. Feed control is carried out stepwise. The design of individual pumps provides the possibility of changing the feed rate due to the use of replaceable parts of the hydraulic unit (sleeves and pistons of different diameters). Drilling pumps, being volume pumps, have the property of self-absorption, but in the descriptive table the accepted characteristic of the suction capacity of this group of pumps is traditionally indicated - the permissible vacuum suction height.

Pumps for pumping out formation fluid from the well, as indicated above, are subdivided into downhole centrifugal, borehole screw and rod pumps. Centrifugal and screw downhole submersible pumping units are part of the units, which in addition to the units contain cable lines and ground electrical equipment. The unit and the cable line are lowered into the well on the tubing. The ground equipment includes a transformer substation and start-regulating equipment. Downhole sucker rod pumps are manufactured in accordance with the requirements of the American Petroleum Institute standard (specification II AX).

Pumps for injecting formation fluid into the well are represented by a group of surface and downhole pumps. The considered surface pumps are horizontal centrifugal sectional multistage pumps of the CNS type. This group of pumps also includes drilling pumps. Downhole submersible pumping units of EDS type for pumping liquid into the reservoir are constructively an analog of pumping units for pumping liquid from wells. For pumping fluids, well pump pumping units of the semisubmersible type ETSNA, in which the motor is mounted on the surface at the wellhead, are also used.

Pumping equipment manufacturers

JSC "Livenskiy Production Association of Hydraulic Machines" ("Livgidromash")

The largest supplier of pumping equipment for the oil producing, petrochemical, shipbuilding industries, energy, utilities, agro-industrial complex and other leading sectors of the national economy of Russia. The enterprise has been operating since 1947 and produces more than 300 pump sizes.

Since 2005, Livgidromash OJSC is a part of the Investment and Industrial Group (IPG) Hydraulic Machines and Systems, which unites the leading manufacturers of pumps and pumping equipment. The products of the IPG enterprises are sold through a single trading division of the Group - ZAO Gidromashservis, as well as a wide dealer network of the company. The company has an extensive service network - more than 20 service centers in Russia and CIS countries.

At present, OJSC "Livgidromash" is one of the largest machine-building enterprises producing pumps and components on the market of pumping equipment. On the territory of Russia and the CIS, the main consumers of the products are municipal enterprises, oil and gas producers, metallurgical plants, nuclear and thermal power plants. For the oil industry, JSC "Livgidromash" produces centrifugal oil pumps (ND, TsN), submersible pumps (ETSNM, EVN), as well as a wide range of different types of pumps for petroleum products;

JSC "Ena"

Created on the basis of the Shchelkovo Pumping Plant, it is one of the leading Russian manufacturers of pumping equipment. The products are widely known on the Russian market and abroad. JSC "ENA" is a full member of the Russian Association of Pump Manufacturers (RAPN).

The enterprise produces more than 250 items, more than 780 standard sizes of centrifugal pumps for industrial use made of cast iron, steels, including stainless, non-ferrous metals and plastics. Pumps for the petrochemical industry: horizontal console electric pumps - AX, X; monoblock chemical pumps - ХМ, ХМЕ; semisubmersible electric pump units - HP, TCI, HIO, HRC, AHP, AHPO, HB; devices for the oil and gas industry - ENG; pumps hermetic with magnetic drive - HG, HGE; centrifugal pumps for ammonia - ASM, ANME;

JSC NPO "Gidromash" / JSC "Kataysky Pumping Plant"

The only legal successor to the All-Union Scientific Research Institute of Hydraulic Engineering (VIGM), founded in 1931 (later - VNIIGIRMASH), which developed 80% of all pumps in Russia and CIS countries. JSC "NPO Gidromash" continues to develop and manufacture pumps for various sectors of the national economy: from nuclear energy and space technology to utilities. The enterprise has its own production base (CJSC "Kataisk Pumping Plant") with unique equipment that allows producing complex pumping equipment, two design bureaus - special and energy pumps, a research laboratory, test stands for the entire range of manufactured pumping equipment.

JSC "Kataisk Pumping Plant" is a leading manufacturer of centrifugal horizontal pumps for the chemical and petrochemical industry, metallurgy, fuel and energy complex, pulp and paper industry, housing and communal services, agriculture, land improvement and other sectors of the economy intended for pumping clean water , condensate, light oil products, superheated water, liquefied gases, sewage, sea and fresh water, chemically active and neutral liquids, for the hearth chi water in domestic conditions, as well as spare parts for them. The plant maintains stable relations with 40 countries. Has a wide dealer network.

Export deliveries of pumping equipment account for 20% (including CIS countries) of total supplies. The plant is a member of the Russian Association of Pump Manufacturers, which represents the interests of all its members in the European Association of Pump Manufacturers "EUROPUMPS";

JSC "Livny Pump Plant of Submersible Pumps" Livnynasos "

It specializes in the production of electric pump units of the "ETSV" type with submersible electric motor, intended for supplying water from artesian wells of urban, industrial, agricultural water supply, irrigation and lowering the groundwater level. Since 1996, Livnynasos has been a member of the Russian Association of Pump Manufacturers (RAPN) and provides about 50% of the needs of pumps in Russia. In addition to Russia, pumps are being sold to all countries of the near abroad.

In mid-2005, the plant mastered and certified 126 standard sizes of pumps by Gosstandart of Russia. As of August 1, 2005, the plant produced more than 360 thousand units of various pumping equipment. In 2006, Livnynasos OJSC during the consolidation of the main pumping equipment manufacturers within the Hydraulic Machines and Systems group;

ZAO NPO "Uralgidroprom"

It is one of the leading manufacturers of pumps in Russia and the CIS. Areas of application of pumping equipment: chemical, utilities, oil, mining, construction, metallurgy. The company's dealer network covers most regions of Russia, Belarus, Ukraine;

JSC "Volgogradneftemash"

It is one of the leading manufacturers of equipment for the gas, oil and petrochemical industries. In 1991 the enterprise became a part of OAO Gazprom. At present, Volgogradneftemash OJSC unites the Volgograd Oil Machine Building Plant named after A.Kh. Petrova (Volgograd) and Kotelnikovsky Valve Plant (Kotelnikovo, Volgograd Region).

Technological equipment manufactured by the Company is equipped with all gas producing and gas transportation enterprises of Gazprom, oil refineries of large oil companies, gas pipelines, gas condensate and oil fields from the Far North to Central Asia. Centrifugal oil pumps and pumping units on their basis are designed for pumping oil, liquefied petroleum gases and petroleum products. Types of produced pumps: TKA (cantilever), NKV and NK (cantilever), NT (two-bearing), TKAM (sealed, up to + 1000 C), C5 / 140T;

FSUE "Turbopump"

Scientific-production enterprise, which includes a design, production and experimental complexes, interconnected by a common production and technological cycle. Currently, the Federal Space Agency for FSUE "TURBONASOS" has assigned the development, manufacture, testing and maintenance of pumps, turbines and power systems for basic industries. Consumers of the products are enterprises of oil and gas production, petrochemical, oil refining, chemical, metallurgical, ore dressing and other industries of the national economy of the Russian Federation;

JSC "Plant of blade hydraulic machines"

(JSC "LGM", until 1991 - Moscow Pumping Plant named after MI Kalinin, Mosnasosmash - one of the oldest in Russia enterprises for the production of pumping equipment with rich experience in the production of high-quality pumps used in various industries: shipbuilding, chemical , petrochemical and oil refining, energy, metallurgy, including for pumping liquefied gases (cryogenic pumps), in public water supply systems and other industries;

OJSC "Uralgidromash"

The manufacturer of hydraulic machines, power, chemical and oilfield equipment, specializing in the design and manufacture of axial, diagonal, centrifugal, submersible pumps and pumps for the chemical, mining, metallurgical, oil, shipbuilding industries, main canals and pipelines, thermal and nuclear power plants, systems of technical and domestic water supply, melioration, irrigation, sewerage and other industries, as well as design and engineering tovlenii hydraulic turbines of small and medium power;

ROSHYDROMASH

Manufacturer and supplier of pumping equipment, electric motors and generators for various purposes. In the range of products supplied, pumps for pumping water and other liquids, including aggressive liquids, oil and oil products, steam and condensate, as well as electric motors for general industrial and special purposes.

Rosgidromash is also a dealer of Vipom AD, Vladimir Electric Engine Plant, ZAO Trade House-KEM, Yasnogorsk Machine-Building Plant, Bavlensky Plant of Elektrodvigatel OJSC, Baranchinsky Electromechanical Plant;

CJSC Talnakh

The Association of Production Enterprises "TALNAH" has been successfully operating in the markets of Russia and the Commonwealth countries since 1994. In 2006, the Fluidbusiness Group was organized on the basis of the Talnakh Association of Industrial Enterprises. The group includes highly qualified specialists in the field of hydraulics and process equipment for industrial processes. The main scope of the Group's activities is the selection, delivery and maintenance of ITT's imported equipment. The assortment of the pumping products of the corporation is very wide and is represented by the following main brands: ITT Flygt AB (Sweden), ITT AC (USA), ITT Vogel (Austria), ITT Goulds (USA), ITT Well Point (Italy)

Talnakh unites 11 enterprises specializing in the development, design and manufacture of pumping equipment, spare parts for pumps, chemical water treatment systems, hydrodynamic cleaning, etc. Among them: ZAO DNS (Dosage pumps and systems), ZAO NPO "Hydraulic technology, JSC NPO "Centrifugal Pumps" and other enterprises.

Manufacturers of oilfield equipment

Production company "Borets"

Produces the entire line of submersible oil-producing equipment and provides services for its repair, monitoring and maintenance. The Borets plant was the first enterprise in Russia to establish serial production of submersible pumps for oil production. At present, the Borets plant produces a wide range of oilfield and compressor equipment: full sets of submersible electric centrifugal pumps (ESPs), ECSC, ECNMIC, ECNM, ESPN, ECNDP, IIETsN, LETsND, LETsNM section pumps, ), screw and reciprocating compressor units, compressor stations, gas injection units (UNG and UNGA series).

The PC "Borets" owns 19 companies in Russia. The main subsidiaries of PC Borets are Lebedyansky Machine Building Plant (the production of submersible centrifugal pumps for oil production, gas separators and jet pumps), the Kurgan Cable Plant (production of heat-resistant power cable for submersible electric pumps), the Borets service company, the Lysvenskiy oil machine building plant.

Also in the structure of the company is LLC "Lemaz", which is one of the leading Russian manufacturers of submersible centrifugal pumps for oil production. It also develops and manufactures centrifugal pumps for pumping petroleum products, piston and plunger pumps of various types and purposes, including for nuclear power engineering and special shipbuilding.

According to the holding, the share of PC Borets in the market of oil production equipment and services (together with its subsidiaries) will be about 21.5%. The Moscow factory "Borets" occupies up to 50% of the Russian market for certain types of equipment for oil production.

One of the leading American companies producing and servicing oilfield equipment Weatherford International acquired a share (less than a third) in the Russian group Borets;

OJSC "Izhneftemash"

One of the largest specialized Russian enterprises producing oilfield equipment. OJSC "Izhneftemash" produces more than 40 types of equipment. Small and medium-sized drilling pumps, automatic stationary drill bits, cementing and mixing plants for cementing wells, rocking machines and deep rod pumps for oil extraction mechanically, pipe hydraulic keys for screwing-unscrewing pipes for repairing wells and much more.

The plant has a powerful technological potential. The range of products includes:

- equipment for oil production,

- equipment for cementing wells,

- fixed drilling drills,

- pumps drilling and pumping units,

- equipment for repair of wells,

- technological oilfield equipment;

Elekton CJSC

For 16 years now it has been offering its solutions and products in the field of oil production in the CIS. It specializes in the production of control stations and associated equipment and equipment for submersible electric motors (EDS) of the "ELEKTON" series intended for operation as part of electric centrifugal pumps for oil production, rod deep pumping units, injection of formation water, water intakes, etc. The share of consumption of ELEKON control stations from the total number of purchases by oil companies in 2008 was more than 60%. CJSC "ELEKTON" has more than 30 patents for manufactured equipment, including contactors, submersible telemetry and control stations for SEM. The release of submersible oilfield equipment developed by ZAO ELEKTON: an in-line screw pump for extraction of high-viscosity oil, starting couplings for the start of submerged centrifugal and screw electric pumps and other equipment;

JSC "Neftemash"

Specializes in the production of oilfield equipment in block-complete execution. The range of products includes more than 90 types of equipment:

- equipment for measuring the flow rate of oil well products,

- equipment for the PPD system,

- pumping stations. Dosage units for reagents,

- equipment for water treatment,

- fire fighting equipment,

- equipment for the preparation of oil, gas and water,

- the building of administrative-household and electrical equipment,

- questionnaires for ordering equipment;

OJSC "Alnas"

It is part of the company "Rimera" - the oilfield services division of the ChTPZ Group, which provides services for the exploration and development of deposits, as well as the design and construction of pipelines. "Rimera" unites the service assets of the ChTPZ Group - the leading manufacturers of components for the construction of pipelines, a network of service centers located in the largest oil-producing regions of Russia. The company also has representative offices in Kazakhstan, Azerbaijan, Ukraine, Uzbekistan.

The assets management of ChTPZ Group is carried out by ARKLEY CAPITAL. In August of 2008. Rimera, which represents ChTPZ Group's oilfield services division, acquired 24.765% of the voting shares of the leading enterprise of domestic oil engineering - OAO Izhneftemash;

OOO "Ritek-itz" and the company "NETZSCH"

A joint Russian-German company, LLC RN - Integrated Pumping Equipment, has been established, which develops, produces and supplies a fundamentally new plant for the production of high-viscosity oil. This installation includes "NETZSCH" submersible screw pumps and special drives for them, developed by RITEK-ITC LLC (for example, a gearless low-torque high torque instantaneous electric drive of a submersible screw pump for UEVN).

OAO RITEK is part of the structure of the production companies of the vertically integrated oil company OAO LUKOIL and belongs to the group of medium-sized Russian oil companies, taking the leading positions on the main indicators in its group;

ZAO Novomet-Perm

The first products were stages of centrifugal pumps for oil production. In 1997, a new type of stage was developed - centrifugal-vortex, and from 1998 started the production of serial centrifugal vortex pumps focused on oil production in complicated conditions, which allowed to create a production of 1 million stages and 2,000 pumps a year.

Today, "NOVOMET" produces submersible full-scale units for oil production, PDP installations and test benches for testing this equipment; provides services for the selection and manufacture of equipment to specific wells; provides equipment on a daily basis; performs current and major repair of submersible equipment; provides research and expert services in the field of materials science, tribotechnics and hydrogas.

A significant contribution to the overall coordination of the sub-sector is now made by the Russian Association of Pump Manufacturers (RAPN). Since 1992, a member of a similar European association EUROPUMP, RAPN interacts with it on integration issues in accordance with market conditions.

Producers of oilfield pumping equipment from the CIS countries

JSC "Bobruisk Machine-Building Plant"

The largest in the CIS manufacturer of centrifugal pumps. The pumping equipment produced by the plant is divided into five main groups: pumps for oil, oil products and liquefied petroleum gases (oil pumps such as NK, NPC, NDS), for highly abrasive slurries (ground, sand), for clean water (water), sewage liquids (sewage, fecal) and pulp (mass).

He is a member of the Russian Association of Pump Manufacturers (RAPN), which is part of the European Association of Pump Manufacturers (EUROPUMP). Geography of sales markets: CIS, Europe, Central and South-East Asia, Middle East and Africa.

JSC Sumy NGO them. Frunze »

Founded in 1896. Now it is one of the leading machine-building complexes in Europe for the production of equipment for the oil, gas and chemical industries and supplies its products to more than 40 countries.

Export is the basis of the production program of the enterprise; The range of equipment, volume and geography of supplies is constantly expanding. Among the partners of the company the leading positions are traditionally taken by the CIS countries - Russia, Turkmenistan, Uzbekistan, Kazakhstan, Azerbaijan, Belarus, Ukraine, and Iran, Turkey, Bulgaria, China, India, USA, Italy, Argentina and many other countries .

For the oil industry, the company supplies to Russia AK-60 well repair and development facilities, clay separators and upgraded CNS pumps to maintain pressure during oil production. In total, the enterprise produced more than 10,000 pieces of CNS-type pumps.

OJSC Sumy Plant "Nasosenergomash"

The largest company in Ukraine and the CIS, specializing in the manufacture of pumping equipment. It produces centrifugal pumps for various industrial sectors, including oil production; free-vortex and vacuum pumps for use in agriculture and industry. The enterprise is a part of the Investment and Industrial Group "Hydraulic Machines and Systems" - an engineering holding possessing the most powerful in the CIS research and production complex in the field of development and production of pumping equipment, power units and complex hydraulic systems for various industries, power, pipeline transport, water management and housing and communal services.

Joint Stock Company Kharkivmash

Specializes in the development of new technologies for the integrated supply of oil and gas producing and oil refining industries, hydro and heat power engineering, and municipal services. He is the founder of NPP "Neftegazovaya Tekhnika", on the production basis of which the serial production of oil pumps such as NK and NKV was mastered. The nomenclature of oil pumps completely covers the range of pumps produced in the CIS countries. The company has mastered the production of other types of pumps, as well as the production of various boiler-auxiliary equipment.

In 2002, the enterprise became a part of JSC "South-Russian Industrial Corporation", which allowed to significantly expand the range of equipment consumers at the expense of enterprises of Russia, Turkmenistan, Azerbaijan, and Uzbekistan. For the oil industry, the company produces the following types of oil pumps: NK, NKV, NPC, pumping units such as CN, PE, oil pumps H and ND.

OOO "Southern Plant of Hydraulic Machines"

Specializes in the manufacture of pumping equipment for all branches of the national economy. The pumps of the Yuzhgidromash plant are successfully operating in 49 countries of the near and far abroad - in the countries of Europe, Asia, Africa, Latin America. Consumers: enterprises of thermal and nuclear power, metallurgical, food, chemical and oil refining industries, in melioration, water supply and irrigation, in systems of dewatering of coal mines and subways, on small boiler houses, in communal services, on personal plots.

JSC "Moldovakhidromash"

It is one of the largest pump manufacturers in Eastern Europe. Within the CIS, the company continues to be one of the main producers and designers of chemical, fecal, marine, circulation, special and other electric pumps. The produced pumps are used at chemical industry enterprises, at oil refineries, in the metallurgical industry and in other industries. The main products of the company are centrifugal sealed explosion-proof electric pumps.

JSC Khidropompa

The output of electric pumps such as ECV, ECW XTrG, ECV XTr, CMVV and OMPV, CMF, Torent, Farmak, Gradinarul, Asvatik.

OJSC "Bugulma Electric Pump Plant"

Manufacture and repair of electric centrifugal pumps (ESPs).

The volume of the Russian market of pumping equipment for the oil and gas industry

The production of pumping equipment is a sub-sector of machine building, but performs mainly a co-function for other industries. The pump is one of the basic structural elements of the infrastructure of such industries as oil production, oil refining, oil transportation, energy, water management, housing and utilities and chemical engineering. The performance of the co-production role determines the dependence of the dynamics of the production of pumps on the state of the above-mentioned industries.

Currently, in the post-Soviet space pumps are produced by more than 200 enterprises, including directly in Russia - 147 enterprises. For comparison: in 1990 in the USSR pumps produced 78 enterprises, 52 of them - in the territory of the Russian Federation.

According to the reports of the companies "Livgidromash" and "Livnyasos", over the past five years, no significant changes in the main components of the market for the production and sale of pumping equipment (all types of pumps) have occurred. Throughout the period 2001-2004. The volume of pump production in Russia remained constant at 5.5 million pumps per year (all types of pumps). The ratio of imported and domestic products sold in the country remained unchanged during the period under review - about 60% against 40% in favor of the domestic producer. In 2005 there was a tendency to revive the pumping equipment market. Thus, the overall increase in production in 2005-2007. amounted to 10-17% of the 2004 level depending on the sector. In 2007, the increase in the production of pumps amounted to 15.4% of the 2006 level.

Pumping equipment sales forecast for 2008 show quite high growth rates - up to 15% per year. A smooth growth is forecasted, due to the manifestation of deferred demand and the need for equipment that provides the implementation of more complex production and infrastructure projects. The deferred demand is determined by the considerable wear of the pump park, reaching up to 90% in some companies.

In the segment of submersible pumps (including pumps in ESP units), according to market participants, the demand for the oil industry amounted to 22650 thousand units in 2007. Volumes of production of domestic companies in this segment were as follows:

- The wrestler - 8 thousand units, the share of 36%,

- Novomet - 3 thousand units, share 11%,

- Alnas - 2 thousand units, share 8%,

- Diamond - 1.4 thousand units, the share of 6%.

In the oil-extracting industry of Russia, CIS countries and worldwide, the production rate of wells for oil production tends to decrease. At well production 2 -: - 20 m3 / day. the use of centrifugal pumps is inexpedient, so deep rod pumps with rocking machines are used. The deep-well rod pumps in Russia are produced mainly by the following plants: OJSC "Izhneftemash", CJSC "Perm Oil Engineering Company" (CJSC "PKNM") and OJSC "ELKAM-Neftemash", Perm.

Some experts note a tendency to reduce demand for sucker-rod pumps. Since rod pumps have a number of drawbacks, in Russia and the United States, work is under way to develop electrohydraulic drive diaphragm pumps with a high head pressure of up to 3,000 m and a supply of up to 25 m3 / day. In Russia, "RAM" LLC developed and tests this pump (EGPDN), and in the USA the company "Smit Lift" produced and tested in 2005 an experimental batch of diaphragm pumps with a head of 720 m and a feed rate of up to 25 m3 / day.

JSC "Livgidromash" tests two-diaphragm pumps with a drive from a rod with a lathe, which leads to a limitation on the pressure characteristic.

In view of the increase in the number of idle wells that are idle and located in hard-to-reach areas, where oil extraction by sucker-rod deep pumps becomes unprofitable, the use of electrohydraulically driven diaphragm pumps is a promising high-tech direction.

In addition, due to the inertia of the diaphragms to the aggressive formation fluid, the diaphragm pumps are used for pumping it in a booster pump, produced by JSC ELKAM-Neftemash, with a capacity of 450 m2 / day. and pressure of 4 -: - 6 MPa, as well as in the high-pressure installation developed by OOO "RAM" of 25 MPa and a productivity of 600 -: - 800 m2 / day. for the system to maintain reservoir pressure directly on the pads. Diaphragm pumps have a high efficiency (at least 60%) and with a modular design allow remote control of performance and pressure.

The market volume for production diaphragm pumps, both in Russia and abroad, can be at least 50% of the existing well stock and at least 50% of the pumps used in the reservoir pressure maintenance system of the transfer pumps. In addition to these advantages, diaphragm pumps can be used in the production of viscous oil, oil with a high content of technical impurities and from greater depths (over 3000 m) in the case of financing by developers from the state or oil companies.

Since the main unit of diaphragm pumps is a self-contained closed hydraulic drive with the use of voluminous oil pumps, cooperation is required between the factories producing the components of the hydraulic drive and the machine-building plants that produce diaphragm pumps. In Russia, the production of diaphragm pumps of a new generation of FSUE Turbonasos, CJSC POTEK and OJSC ELKAM-Neftemash is starting to develop.

In the segment of screw pumps, the demand for the oil industry was 1500 pcs. in 2007, the main players-producers in this segment - Borets, Livgidromash, Elekton, Ritek.

According to JSC "Livgidromash", in the segment of pumps for oil and petroleum products (NDV, VAT), the shares of the companies of Bobruisk Engineering Plant and JSC Volgogradneftemash account for 5% of the market.

According to Rosstat official data, there is a steady growth in the production of various types of pumps (not only for the oil industry). The largest part is accounted for by centrifugal pumps (37-38% of the total volume of produced pumps). A significant proportion of the total volume of pump production in the Russian Federation consists of centrifugal artesian pumps and submersible pumps (10-12%). The total number of pumps produced of all types (including pumps for water and domestic pumps) increased from 610.3 thousand in 2004 to 738.8 thousand units in 2006.

The oil-extracting industry, as the most important component of the fuel and energy complex of Russia, is the basic basis of the country's national economy. The rates of oil production growth achieved in Russia in recent years were among the highest in the world. The growing world demand for oil is an important incentive for domestic companies to actively develop, build up oil production capacities, commission new fields.

The most important indicators of demand for pumping equipment in the oil industry are: operational and exploratory drilling, commissioning of new wells, positive dynamics of oil production.

According to the assessments of participants, the market of oil and gas equipment in 2008-2009 will grow by 20-30% per year, while the interest in high-tech equipment from consumers will increase.

Trading Engineering Companies

Among the companies that do not manufacture pump equipment but provide services for its sale (intermediaries, dealers), one can single out Rosenergoaplan, PromSnabComplekt, Agrovodkom, Energomashsystema, Gidromashsher-Vis, , JSC "Ventilation, water supply, heat supply" ("ВВТ"), "Electrogidromash", PIC "Energotrast", "Central Pumping Company", "Energoprom" and others.

Another segment is companies performing a full cycle of works: design, construction, production / supply, installation, commissioning, oilfield equipment service. This segment includes such companies as Baker Hughes, Alnas, Elekton, OAO RITEK, Gidromashservis, Novomet, Gazenergokomplekt, Industrial Power Machines, Schlumberger.

There are also service companies that do not manufacture or sell equipment, but provide a full range of design and service works.

According to experts, the volume of the service market in 2007 increased 1.5 times compared with 2006 and amounted to about $ 400 million. Positive dynamics of growth in the segment of service services will continue. According to some experts, the volume of this segment will amount to about $ 900 million by 2015. It is interesting that the service market is growing faster than the sales market of the equipment itself, which is connected with the development of technologies and increasing requirements for quality maintenance of modern equipment.

The development of service services is also facilitated by the tendency of the wells to be withdrawn from service by own subdivisions of oil companies and the transfer of services to independent service companies (at present the total well stock is 76,300 units, of which only 28,600 are serviced by external service companies with which companies such as BP , Lukoil, Yukos and others).

Foreign manufacturers of pumping equipment

For a long time, foreign countries have been working extensively on the domestic market. Anticipating the review of the nomenclature of the main foreign companies active in the Russian market, one can note the most common signs characterizing the equipment of foreign firms.

1. Wide limits of parametrical areas of work of pumps, in some cases overlapping the parameters of the operation of domestic pumps.

2. A wide range of options for the design of pumps for different operating conditions. It should be especially noted a group of multi-stage vertical pumps, which are practically absent in the nomenclature of domestic producers.

3. High quality of materials used in the manufacture of pumps. The nomenclature of materials used by foreign companies practically coincides with the nomenclature of materials used in domestic pump building, however imported materials and castings are of higher quality than domestic ones.

4. A wide range of pump configurations with various automation components, measuring instruments and start-protection devices, pipeline fittings and other types of components.

5. The list of companies offering units to the consumer with built-in frequency regulators for the number of motor revolutions controlled by a remote operator or automation system is expanding.

At present, the following companies are most active in the Russian market of pumps used in the oil industry:

- Reda (Schlumberger) Electric Submersible Pumps

- Baker Hughes (division Centrilift) submersible electric screw pumps LIFTEQ; screw pumps with rod drive; horizontal pumping systems

- Wood group (england) Multistage centrifugal pumps companies

- Weatherford (USA) Rotary screw pumps Electrocentrifugal submersible pumps

- "Vipom" (bulgaria, aO "viPOM") Pumps of the "DV" series With the wheel of the two-way inlet Pumps of the "E" series Console, console monoblock Pumps of the "E-ISO" series Console, console monoblock Pumps of the "KEM" series Console monoblock Pumps of the " MTR »Multistage Pumps of the series« 12ЕСГ »Self-priming

- NETZSCH (Germanium, Pamps Rus LLC) Single screw pumps NETZSCH - Reagent dosing Horizontal pumps NETZSCH - PFD systems Horizontal pumps NETZSCH - Drainage of tank trucks Multiphase pumps - Intrafusion pumping Submersible screw pump units

- "Vornemann" (germanium) Rotary high-pressure pumps "LEISTRITZ" (germanium). Screw Pumps Multiphase Pumps

Centrilift pumps occupy about 4% of the total sales of pumps for the oil industry (together with the service share of Baker Hughes is 9%), and Wood group has a share of about 2% of the market (together with service services - 4%).

According to experts in the oilfield equipment market, in 2007 the market volume of pumps for the oil industry (not including services) amounted to about $ 800 million, and in 2006 this figure was equal to $ 750 million. The forecast value of the market volume in 2015 $ 1.1 billion.

Pricing in the domestic market of pumps

The prices of pumps for the oil-extracting industry are determined not only by common factors (cost price, delivery terms and prices of competitors), but also by many additional opportunistic factors, incl. world oil prices. The average price of a pump for oil production in 2007 was $ 36,700 per installation (domestic production). Imported products are 1.5-2 times more expensive.

The deviation of the technical characteristics of pumps from nominal values and low quality indicators not only significantly reduce the price of the pump, but sometimes force production and commercial firms to refuse to purchase the proposed equipment. The latter is due to the desire of firms to maintain their reputation in the market, as well as to reduce the costs of pre-sale preparation.

The price of the product in the domestic pumping market is determined by the following main factors:

- monopoly of the manufacturer;

- quality of the product;

- place of assembly and pre-sale preparation.

In addition, the price of pumping equipment is affected by a number of other factors that may prove to be very significant: guaranteeing the purchase of equipment after long-term storage (a distinctive feature of the domestic market of pumping equipment is the availability of a large number of pumps for a long time in stock, for the implementation of such equipment with a guarantee of reliability it is necessary to produce a thorough pre-sale preparation, which usually consists of dismantling aggregates, replacement of bearing assemblies and seal assemblies, replacement of parts included in the ZiP, replacement of electric motors, as well as in painting and preservation, as a result of the price of these pumps on the market below factory prices by 35-50%), the impact of transport costs.

Trends in the Russian market of pumping equipment for the oil industry

At present, the Russian market of pumps for the oil industry can be characterized by the following trends.

- The confident development of the oil industry explains the growing demand for complex integrated pumping systems that require individual engineering solutions and determines the tendency of the transition from the core consumption to the complete one, in which cooperation involves not only the supply of equipment, but also its installation, maintenance and "withdrawal to the regime".

- The intellectualization of the management and maintenance of pumping systems, the creation of "intelligent wells" that function successfully in the Middle East, exist in the Russian Federation at the level of pilot projects; in the future - the creation of "intellectual deposits".

- Lagging of the material and technical base in comparison with foreign firms - the leaders of pumping production, which is reflected in the fact that imports are growing faster than their own production, there is activation of foreign competitors.

- Lower cost of domestic production compared with foreign counterparts.

- High moral and physical wear of pumping equipment;

- Tougher requirements from consumers to the technical characteristics of pumps, increased service life of equipment and time between failures.

- Given the decline in the production rate of oil wells in Russia, which share in the total volume is up to 50%, there is growing interest in new high-tech pumps for low-yield wells.

- Consolidation of manufacturers of pumping equipment for the successful development of the domestic equipment market - major players that occupy a significant market share, are able to invest in renewal of fixed assets and expansion of production.

From the analysis of changes in the structure of the output of pumping equipment, one can draw a general conclusion about a noticeable increase in the proportion of complex and expensive pumps. Imported by the domestic oil industry, imported submersible equipment served and serves as a catalyst for the rapid development of Russian machine-building companies in the oil and gas sector, their technical growth is the general director of Novomet-Perm CJSC Perelman Oleg Mikhailovich. There are positive trends in the cooperation of oil companies and producers.

Oil companies, appreciating efforts to improve the quality and reliability of submersible equipment, invite domestic machine builders to participate on an equal basis with foreign firms in tenders for the supply of complex and high-performance pumping equipment.

Pumps designed for pumping oil and petroleum products are used in oil production processes: during drilling operations, pumping out formation water from wells and injecting formation fluid into the well. These pumps are divided into three groups. Some types of pumps are used at the stage of pumping oil through field and main oil pipelines. "/\u003e

Oil centrifugal pumps designed to work in conditions of possible formation of explosive mixtures of gases and vapors with air are used in process units of oil refining and petrochemical industries for pumped oil, liquefied hydrocarbon gases, petroleum products and other liquids similar to those indicated in physical properties (density, viscosity etc.) and corrosive action on the material of pump parts. The maximum content of solid suspended particles in the pumped liquid should not exceed 0.2% , and their dimensions are 0.2 mm.

Pumps are manufactured in the following types: K - cantilever horizontal one- and two-stage; C - horizontal sectional inter-bearing with axial connector housing; SD - horizontal sectional inter-bearing double-hull; BM - vertical, built into the pipeline.

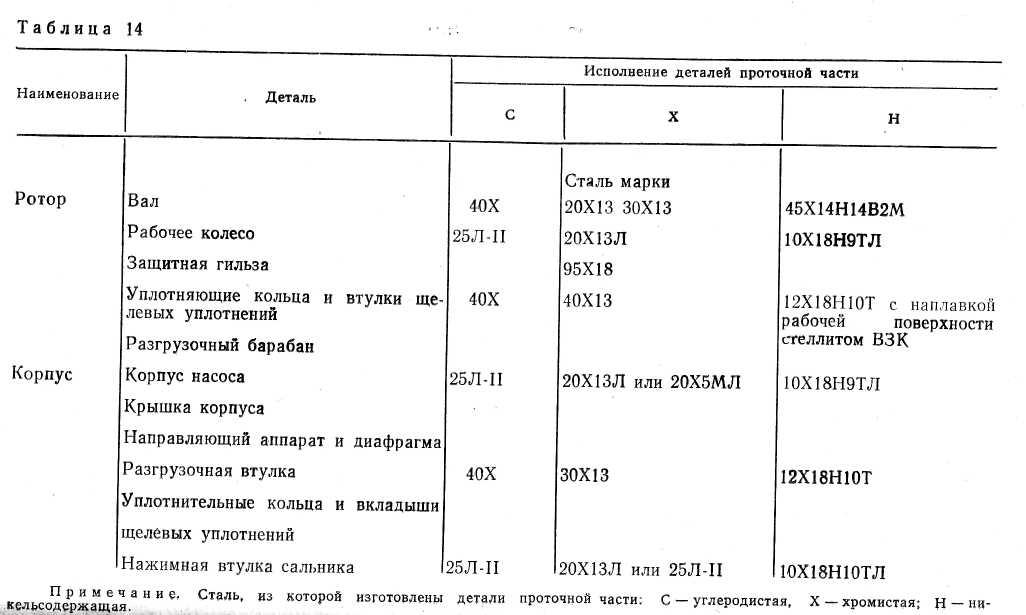

Depending on the temperature of the fluid being pumped, one or another steel is used to make the parts of the flow-through part of the pump (Table 9).

Table 9

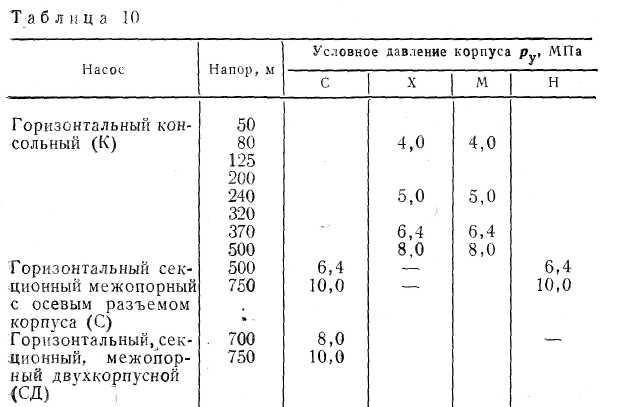

The conditional pressure of the hull is one of the parameters determining the compliance of the selected pump with the specific operating conditions for which the pump body parts are calculated (Table 10), with the inlet pressure at the pump not exceeding: for pumps of types K, C, 2,5 MPa, for pumps of type BM - 1,0 MPa.

Table 10

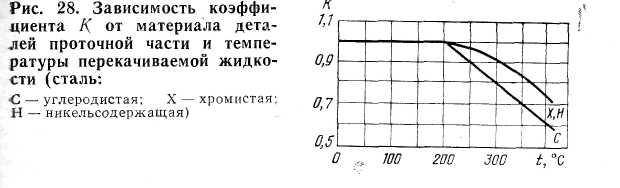

The operating pressure at the pump outlet should not exceed R Have TO,where TO- coefficient determined by the schedule (Figure 28), depending on the material of the body parts and the temperature of the pumped liquid.

In the shaft exit points, stuffing boxes (with or without bolt feed) are installed from the pump casing, or face single or double seals, interchangeable by connecting and landing dimensions for a pump of each brand.

Marking of the shaft seal:

stuffing box - CO;

gland chilled with the supply of a seal liquid - SG;

single face with flow circulation of liquid pumped by pumps - OP;

face single with an independent circuit of circulation of the liquid pumped by the pump - OK;

single face with an independent circuit of circulation of the fluid pumped by the pump and a heat exchanger of the pump shaft - RT;

double face with the circuit of the circulation of the gate liquid in the heat exchanger of the pump shaft - DT;

double face with a circuit of circulation of the gate liquid - DC.

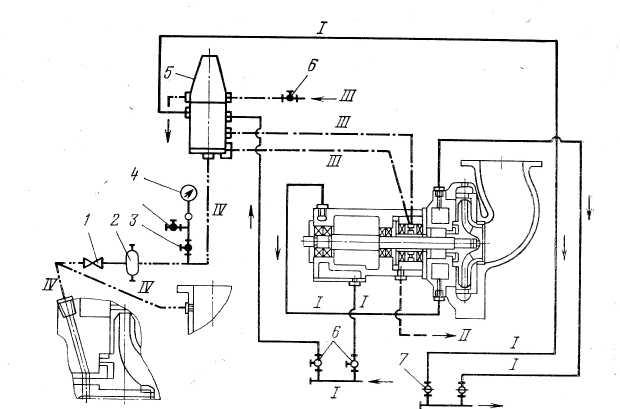

To cool the oil in bearings and shaft sealing assemblies, use a liquid (fresh water or antifreeze) supplied through auxiliary pipelines in the cavity in the corresponding parts of the pump. Mineral oils are used as a sealing liquid for a stuffing box or double mechanical seal: industrial 20, turbine 22, transformer and others with a viscosity of 10-30 mm 2 / s (at 59 ° C). The approach and removal of the gate liquid is also carried out by auxiliary pipelines, which are assembled according to the operating conditions of the pump according to one of the typical schemes (Fig. 29).

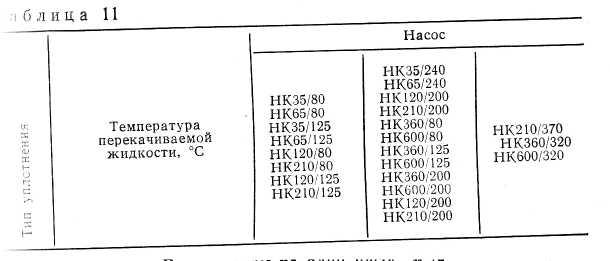

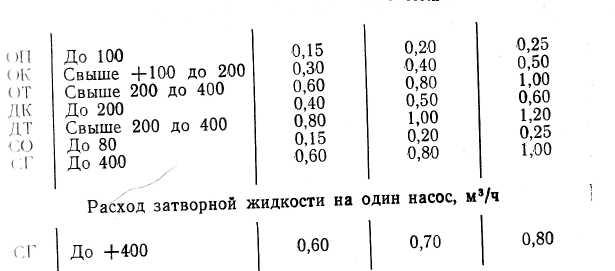

The flow rate of the cooling and gate fluid for pumps of the NK type is shown in Table. eleven.

Pumps type TO, designed to work in the systems of oil gathering and transportation, are produced in a special version with cooling of units and parts with pumped liquid.

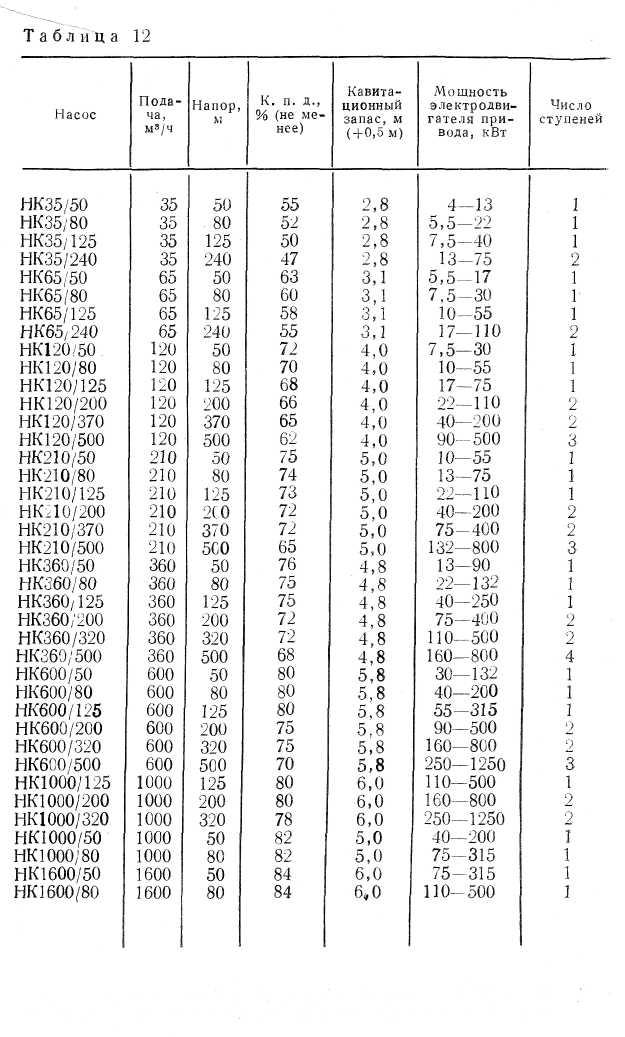

The main technical characteristics of a pump in type K for a pumped medium with a density of 1000 kg / m 3 and a viscosity of 0.01 cm 2 / s are given in Table. 12.

Single-stage pumps with a feed of up to 250 m 3 / h are manufactured with a one-way impeller, pumps with a flow of more than 250 m 3 / h, with a double-entry impeller.

TO  each pump can be manufactured with impellers of one of four output dimensions, diameter: nominal (option a) and turned (variants a,c and d) that provide the corresponding Q-H characteristics.

each pump can be manufactured with impellers of one of four output dimensions, diameter: nominal (option a) and turned (variants a,c and d) that provide the corresponding Q-H characteristics.

Fig. 29 Basic hydraulic circuit of the pump with a DK seal:

1, 3 and 6 - valve, respectively, shut-off, lock needle and needle; 2 - separating vessel; 4 - manometer; 5 - spring-hydraulic accumulator; 7 - the index of submission; pipelines: I - cooling liquid; II - drainage; III - sealing (sealing) fluid; IV - transfer of momentum.

The pump body, cast in conjunction with the support legs, inlet and outlet nozzles, is installed on the foundation plate posts. The support surfaces of the legs are located in a horizontal plane passing through the axis of the shaft. The lid is connected to the body on the drive side, the joint between the flanges of the lid and the body is sealed with a spiral wound gasket.

The shaft is mounted on two supports - ball bearings mounted in the bearing bracket, which is connected to the foundation plate by the support arm and to the housing cover by the flange. The bearing support on the drive side consists of two radial-thrust bearings that receive axial and radial forces. Between these bearings set picking washers, creating a preload in the bearings. The inner rings of the bearings from the axial movement are fixed with a washer and nut, which simultaneously attach the half-coupling of the gear clutch and the spacer sleeve. Another bearing bearing of the shaft (two radial ball bearings) is provided for the perception of radial forces.

Table 11

Pumps with a drive are mounted on a common foundation plate. Their shafts are connected by means of a gear clutch with an intermediate shaft. In this case, the length of the intermediate shaft allows you to disassemble the pump without dismantling its housing, motor, inlet and outlet pipeline. The gear coupling has a guard rail which is bolted to the foundation frame.

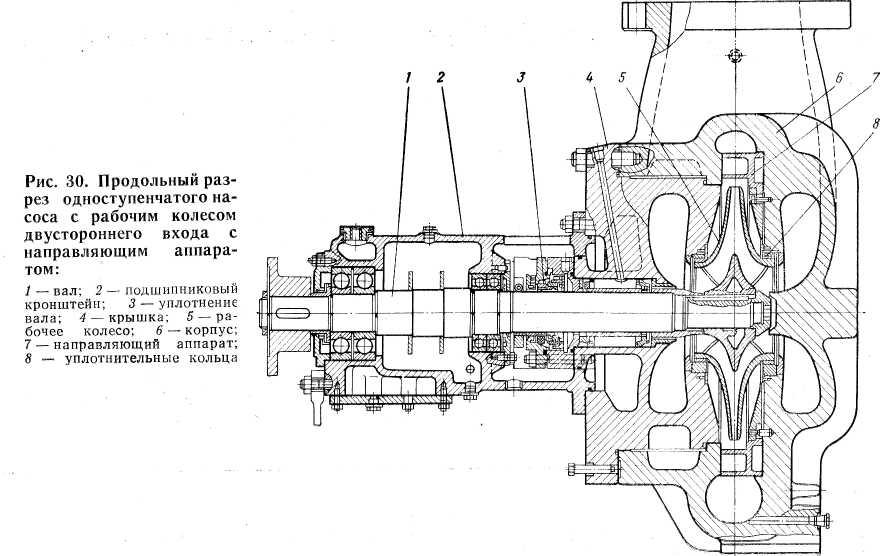

Pumps of type K are manufactured with a guide device or with a spiral housing.

The guiding device is dismountable, it consists of four parts. It is located in the circular boring of the body. If the pump is designed with a spiral housing, the spiral bend is double designed to balance the radial forces acting on the rotor.

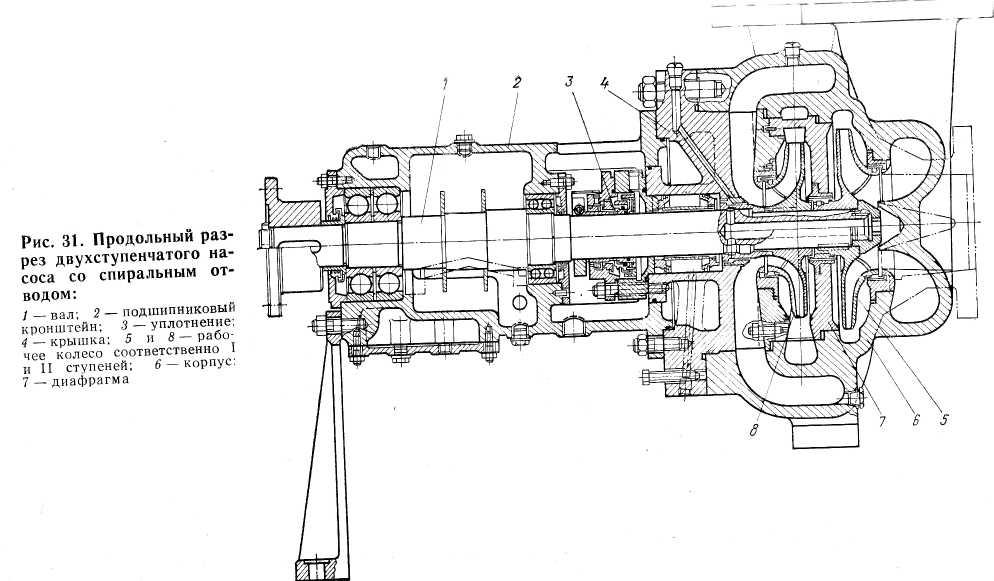

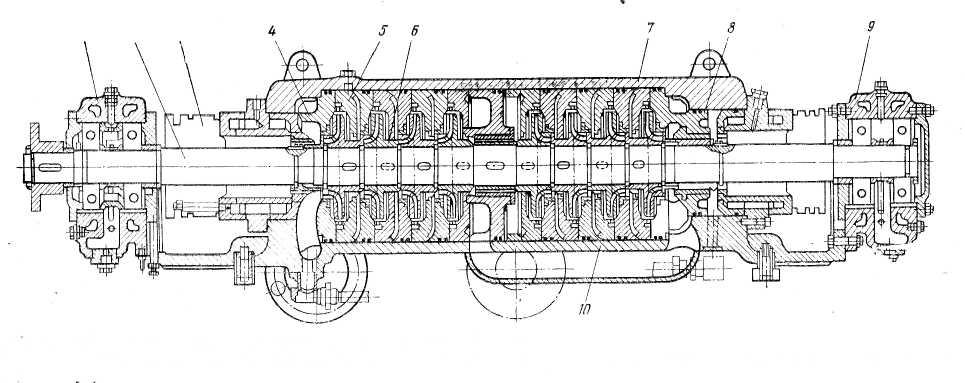

Pumps type C and SD. Sectional inter-pump pumps are divided into two types: HC - oil sectional and NID - oil sectional double-hull (Figure 32). The main technical characteristics of pumps of this type for a pumped medium with a density of 1000 kg / m 3 and a viscosity of 0.01 cm 2 / s are given in Table. 15.

Note:The rotational speed of the shaft of pumps of the types NK35 / 50 - NK1000 / 320 is 2950 min -1, the pump types NK1000 / 50 - NK1600 / 80 - 1475 min -1.