The appearance of the creaking flooring is not enough for anyone to enjoy. If nothing is done, the squeak can become stronger. Various floor coverings, including laminate flooring, can creak. This material is considered a high-strength, wear-resistant coating, but it eventually wears out. When walking on a laminate floor, unpleasant sounds can be observed, which can become more distinct and louder. Noise can not only act on your nerves, but also be the first signal that a floor covering needs to be repaired. So why creaks laminate what to do indiscriminately to quickly eliminate such a nuisance.

Laminate is considered to be a strong material, but it also wears out. This is due to the fact that it is constantly exposed to pressure, which causes the appearance of various defects. It is necessary to carefully investigate why the laminate can creak and what to do in these cases.

Uneven base

Often the appearance of the creaking is due to the uneven surface of the base on which the laminate was laid. Perhaps before laying it was not well prepared. Small pits, knolls, deformations can become the main factors of the appearance of unpleasant sound coming from the floor when walking.

Some tips for preventing this unpleasant problem:

- be sure to prepare the base under it before laying the floor covering;

- it is worth remembering that the laminate is quite demanding to the base, the slightest pit, the tubercle, will cause deformation, the appearance of unpleasant squeaks;

- if the creaking appeared, then in this case it is necessary to align the base. To do this, you need to remove several panels at the site of the appearance of the creaking;

- with a cement mortar, all defects in the floor surface should be well sealed;

- all must be left to dry out;

- the substrate is laid, the panels are inserted into place.

Substrate Thickness

Sometimes thick substrates are acquired in order to smooth out all the pits, irregularities. However, this is not a solution, on the contrary, everything will get worse. Some tips for preventing defects due to the substrate:

- the size of the substrate thickness is 2-3 cm;

- if the substrate has a thick structure, then after its laying, there will be an increased sagging of the laminate. This will lead to the appearance of a squeak;

- before laying the laminate, make sure that the substrate is thin, otherwise it may be necessary to repair the floor covering or replace it completely.

To prevent the appearance of noise from the floor, it is necessary to remove the entire coating and lay a thinner substrate. If you do not want to disassemble the floor, you will have to get used to the noise until a complete floor replacement is made.

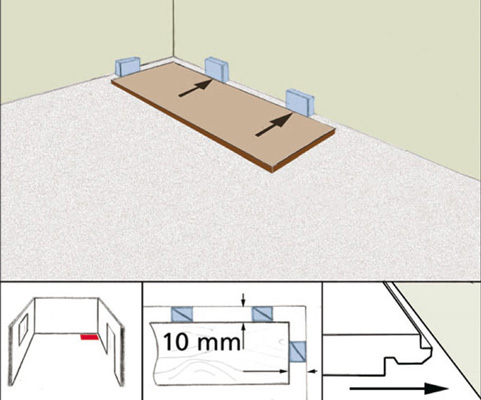

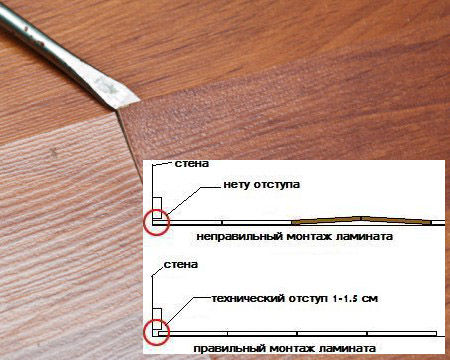

A small gap between the laminate and the wall

In order to avoid noise from the floor, when installing a floor covering between the laminated floor and walls, leave a gap. The width of the gap should be 7 mm. In spacious rooms, the gap can be 2-3 cm, it all depends on the width of the plinths to be laid.

The presence of a gap makes it possible for the laminate cover to disperse so that in the future it will take a comfortable position. The gap removes the tension from the joints of the locks, and the surface of the floor covering protects against the appearance of squeaks.

If there is no gap or its size is small, during expansion, there will be an emphasis of the laminate in the walls and in the skirtings, which will cause noise, creakness of the floor surface.

In order to eliminate this problem, it will be necessary to remove the skirting boards, reduce the width of the edge panels of the laminate to the optimum space between the laminated floor and the walls. After that, you need to install the baseboard back, fix it all.

Clearance between plinth and laminate, wall and laminate boards

Clearance between plinth and laminate, wall and laminate boards Variable humidity in the room

Laminate material can react to changes in humidity. With a sudden increase in the humidity level in the room, the laminate flooring begins to crackle and creak. In this case, the noise appears not in one place, but across the floor. When the level of humidity changes, creaks disappear.

Cryptic sex can be normalized with the help of advice:

- usually the creakiness disappears when the season changes;

- if the creakiness appeared in the summer, then you should wait for heating. Perhaps in this period the creaks and noise will disappear;

- if squeaks appear during humidity changes, then in time they will disappear. To do this, it just takes time for the laminate flooring to become familiar in the new microclimate and cease producing unpleasant sounds.

Due to high humidity, there may be problems with the laminate coating

Due to high humidity, there may be problems with the laminate coating Dust and sand

When installing the floor covering, make sure that the entire surface is clean. It is desirable to constantly with laminated boards, substrates and bases to remove dust, all dirt, sand. Therefore, when laying a laminate with you need to have a vacuum cleaner. In this case, the basis for the floor should be sawn in another room.

What consequences can cause dust, sand on the laminate:

- if the sand and dust hit the joints of the panels, then as a result, it can cause a loud crunch;

- noise from the crunch can cause not only irritation, but also lead to spoilage of the joints;

- the appearance of a squeak, a crunch can be observed even in the screed, but on condition that it is of poor quality.

Before laying the laminate, the floor surface should be cleaned as much as possible

Before laying the laminate, the floor surface should be cleaned as much as possible If the laminate grinds while walking, the reason lies in the accumulation of dust and sand, then it is rather difficult to eliminate this problem, especially if the dust accumulates in the area of the joint locks. If the whole thing is in a poor-quality screed, then for this it is necessary to disassemble the site with a creak. The screed should be poured over the new grout, leveled, dried, primed and stripped. After that, the floor covering is reinstalled. During laying the screed must be well primed, this will protect it from further shedding.

Use of poor-quality material

Another reason, because of which the floor of the laminate creaks, can be the low quality of the floor material. When laying a low-quality laminate, even the main qualities of flooring can not prevent squeaking:

- a quality foundation that is perfectly aligned;

- no dust, dirt, sand when laying the floor;

- the correct size of the gap;

- the desired thickness of the substrate.

Using a low-quality laminate

Using a low-quality laminate The main weakness of a poor-quality laminate are locks, they have different sizes. An unpleasant scratch can appear when walking on the floor. These scratches are eliminated only by a complete change of the floor covering.

The advice for the future should only be acquired by proven manufacturers. It must have high quality, good strength, durability. Of course, the cost of this coating will be much higher, but after laying it will not creak, crackle, and also swell, deform.

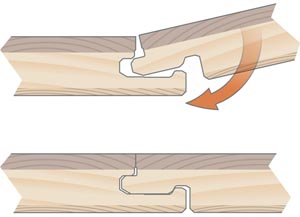

Voltage in the lock elements

Another reason for the creaking of the laminate floor may be the pressure in the junction of the locks. This problem is quite common. And it can appear in a material with high quality. The coating with high quality noise is observed for several weeks and lasts up to a month.

Laminate lock - the main place of origin of the creaking

Laminate with high quality can maintain a tense state in the locks for a certain period of time, after laying it floats for a while until it takes the necessary position. During this process, the coating is adjusted to the shape of the room, under the surface of the base, and also under the features of the patency.

Therefore, when laying the laminate, you should leave the necessary gaps near the walls. If they are, then the laminate coating will take a comfortable position. As a result, all extraneous sounds, creaks, disappear, the floor will become flat. This process usually takes 2-3 months.

The lock is not fully latched

The lock is not fully latched The presence of debris under the laminate

If the installation of laminate coating is made correctly, a space is provided between the wall and the floor, but unpleasant sounds still come from the floor covering. Perhaps under the laminate there is garbage. In this situation, you will need to dismantle the flooring.

Council, if the laminate is of good quality, you do not want to disassemble it, then you can leave it as it is. All rubbish peretretsya, disperse all the grains of sand, various rubbish. Over time, the creak of the floor completely disappears. But there is also a negative side - the lower layer from this can be seriously damaged, which as a result will negatively affect the quality of the entire floor covering.

How to make garbage collection:

- you need to remove all laminate boards;

- the substrate is removed;

- it is necessary to clean the base of all garbage, litter. It would be nice to use a vacuum cleaner, there should not be garbage on the surface of the base;

- a new substrate is spread;

- in the end, a laminate is installed.

Carefully remove the laminate laminate

Carefully remove the laminate laminate If you have a house in your apartment, you hear a creak, then you need to understand why the laminate creaks. Many immediately think about analyzing or completely changing the floor covering. But you do not always need to parse to eliminate the hated noise when walking on the floor. If the house suddenly began to creak laminate, then what to do in these cases, and most importantly how to fix it indiscriminately?

- how to eliminate the local creak - to get rid of the local squeak you will need a paraffin candle, it will need to be heated. Hot wax is poured into the places of creaking, also with the help of it is mashing all the cracks. Grout is done with a thin spatula made of plastic material. There will be a good result if the whole process is performed by an old plastic card that has long since retired;

- how else can you get rid of the creaking laminate what to do indiscriminately? If there is creaking of the floor next to the walls, then you need to remove the panels. All joints can be sealed with a mounting foam or filled with PVA glue;

- if creaking of the floor is observed in the center of the room, then in this case it is necessary to drill holes with a diameter of 0.6 mm. PVA glue is poured into this hole using a syringe. After that, we leave everything to stand until the glue is completely solidified. For 2 days it is not recommended to step on the surface with glue;

- if there is walking, creaking rapids, they should be glued with a transparent adhesive solution;

- to eliminate the creak it is possible to pour a small amount of oil into the drilled holes in the laminate boards;

- filling cavities, pits, deformations on the surface of the base with mounting foam.

Plinth for laminate - minimum clearance required

Plinth for laminate - minimum clearance required  Joints are filled with glue

Joints are filled with glue Prevention

In order to avoid the creaking of a laminate floor, it is worth using important recommendations:

- it is not necessary to save on laminate - it is recommended to purchase an expensive floor covering with sufficient thickness;

- it is desirable to use a cover with a rigid structure, its thickness should be 3 mm. Do not use thick substrates, they can cause intense scratching of the flooring;

- before proceeding with laying, it is better to prepare the ground in advance. It must be cleaned of excess debris, dust, sand. It needs to be well leveled;

- before laying a laminate, it must be held for some time indoors at room temperature;

- when installing, you need to carefully snap the lock connections, it is desirable to punch them;

- necessarily between the walls and the floor covering to leave a gap around the perimeter of the room;

- if there is a possibility, then it is necessary to install a climate technique that will regulate the temperature regime in the room.

The crease of a laminate covering is an unpleasant defect in the floor, which can cause serious problems. As a result of the appearance of this malfunction, the whole coating may suffer, up to complete wear and tear. If there was an unpleasant noise when walking on the floor, it is better to eliminate it immediately, otherwise you will have to change the entire floor.

Video on how to eliminate the creaking of laminate

The form shows how to properly lay the laminate, so that later there are no extraneous sounds when walking on it.

Laminate flooring transforms any room, giving it a respectable look. But also this new material for a number of reasons can become a source of certain inconveniences, for example, in the form of the creaking of separate floorboards.

If the laminate grinds what to do? This question arises almost every homeowner, if such a noise accompanies the tenants while traveling around the house. Do not think that such a phenomenon is the norm. This sad fact speaks only of the fact that during the installation of the floor covering, the technology of the process was somehow broken. Any flaw that leads to unpleasant noise can be corrected, but only first you need to find out the reason for its appearance.

It should immediately be noted that even experienced professionals who have long been engaged in the installation of this coating, always talk about the "capriciousness" of the laminate, since it primarily requires a perfectly flat base.

Some customers refuse to listen to the warnings of the master and ask for installation on the existing basis, without his thorough preliminary preparation. But this may be the first reason for the creaking of the laminate. However, it also happens that everything goes well, and the coating serves for many years without any negative manifestations.

Quite common are cases where the work is done in full accordance with all developed technologies and on absolutely equal footing, and the laminate, after it is properly laid, still produces unpleasant ear sounds. Sometimes, after some time, the panels are rubbed against each other, they sit down and the script crashes, but this does not always happen, and one has to make efforts and look for a way out of the situation.

The reasons for the noise and squeak can be several, and it is not enough just to list them. You should consider each of them separately to understand how to deal with the noise of the coating.

Uneven or unstable base

As mentioned above, most often the cause of the creak is an uneven or shaky foundation for laying the material. To be sure that it will not cause an unreliable scratchy floor, although covered with expensive laminate, it is necessary to make its alignment.

One of the most common causes is the uneven surface of the base

If, however, the laminate has already been laid on an unprepared basis, and the creak appeared on its individual sections, it means that in these places the base of the unevenness (depressions) is maximal, and the decorative coating can be bent when applying a load to its surface. When you change the position of the panel while pressing it, the friction between the individual adjacent elements of the laminate floor occurs, which becomes the cause of the creak.

If, while walking on the cover, the squeak is heard not in separate areas, but practically on the entire surface, then the entire base absolutely exactly requires alignment.

Troubleshooting

- When scratches appear on small areas of the floor, you can perform local repairs by dismantling individual panels. In order to work neatly, you first need to remove the thresholds and plinths that fix the laminate in the repair area. When removing the cover panels, they are recommended to be numbered on the reverse side, indicating the number of the row from the wall and the arrangement of the element in the row, so that there is no confusion when re-installing.

- Having removed the laminate panels and making sure that the deepening in the surface of the base was the culprit of the squeak, a flaw must be eliminated.

- The process of leveling is best done with a quick-hardening mortar, which is spread with a spatula to the general level of the base floor.

- After the mixture has dried, the leveled place needs to be sanded, since even a slight elevation or groove can not correct, but exacerbate the problem.

- A thin cardboard is laid on the dried surface of the substrate, the substrate is returned and the laminate is re-installed.

- If the coating is bound everywhere, no matter where it comes, it means that the original laying was of poor quality. In this case, it is necessary to disassemble the coating completely.

Next, the base should be leveled. It will be more convenient to do this with the help of liquid self-leveling floors, since such a solution will fill all the depressions and make the surface perfectly smooth.

- If the laminate has been laid on a wooden floor, then perhaps it is the boarded base that caused the creaking of the laminate, since the boards may lie unevenly or move away from the lags on which they are laid.

- In this case, it is necessary do a great job. First of all, it will be necessary to remove skirting boards and thresholds, and then the entire laminate.

- Then you will have to inspect the wooden floor and find the "problem areas" on it. Particular attention is paid to the floorboards, which have obvious signs of "decrepit" wood, mold stains or fungus - such parts are subject to unconditional replacement

- In case there is no possibility to carry out the process of barking, the boardwalk can be leveled using plywood with a thickness of at least 10 mm. Plywood must be mounted on the glue with fixing screws.

On top of the board or plywood sheets are covered with a substrate, on which the laminate is later mounted according to all the rules of technology.

Video: several techniques for repairing or replacing laminate flooring

Invalid substrate selected

When buying a laminate, you need to remember that its manufacturer always recommends buying a certain substrate under it. If once it was decided to save money, and in accordance with it for a flooring under the laminate is purchased a material of poor quality, then you should not expect an excellent result. Alas, but inexpensive substrates very quickly crumble and collapse. And this process can take place unevenly, and as a result, the laminate will lie unevenly, and over time, the coating will start to make a creak or crunch.

In addition, you need to be well aware that it is impossible to align an uneven base with a thickened substrate, since it should be exactly a rigid surface. Such a substrate on an uneven surface will eventually break and tear, so do not buy a material thicker than 3 mm.

Troubleshooting

In this case, there is only one solution to the problem - it is completely dismantle the laminate, and then remove the substandard substrate. At the same time, it is worthwhile to conduct a close inspection of the base, and if you want to align it, you need to do this with the help of self-leveling of the filling floor.

Usually manufacturers of laminated panels recommend types of substrate - these tips should be followed

Rubbish under the laminate

Cracking and creaking in moving around the laminate can also occur if the base, before the flooring, has not been sufficiently cleaned from various litter, such as small pieces of construction debris, ordinary sand or small pebbles.

Fallen under the laminate foreign elements can not manifest themselves immediately, because they will be covered by more non-sagged substrate. However, over time, under the influence of loads, the material of any substrate necessarily crumples, and if under it there were even small solid fragments of rubbish, when they come into contact with the laminate, creaks will be heard. Moreover, these decorative panels can be spoiled, and they will have to be completely replaced.

Because of such an oversight, as an unqualifiedly cleaned foundation, you may have to redo all the bulk and costly work.

Troubleshooting

To remove from the ground all unnecessary, you need to perform the following manipulations:

- First, plinths and skirts are removed - this can only be done in those areas of the floor where you can hear a squeak when pressed.

- Further, the whole cover is dismantled, or only that part of it, under which it is necessary to clean.

- The next stage removes the substrate, which, most likely, will have to be replaced, since it can already be spoiled by solid fragments of debris.

- Then, you need to thoroughly clean the base, and it's better if a vacuum cleaner is used for this, and then a wet cleaning is done.

- A new substrate is laid on an absolutely clean surface, and a laminate is laid on top.

- The final action is to secure the skirting boards and flaps.

Sharp change in temperature and humidity

A sharp, abrupt change in one of the parameters characteristic of the existing normal microclimate in the room can negatively affect the laminated coating. Under the influence of high humidity or a radical change in temperature, the decorative coating can begin to creak or even deform.

For example, after the autumn cool weather, the heating season begins, and the material must adapt to higher temperatures and dry air in the premises. Humidity rises during rainy autumn and spring days, and its effect on laminate layers is particularly damaging. Panels of floor coverings can swell or, on the contrary, dry up. It is these processes that lead to unwanted sounds.

After the recent laying of the laminate and during its adaptation to the conditions of a certain room, similar phenomena can also arise. In this case, there is no need to rush to correct them, since, perhaps, the material needs to be given time for its "getting used" to new conditions.

If the laminate creaks only in the off-season, and at the established temperatures and humidity "subsides", then there is only one effective means to avoid this negative. It is necessary, if possible, to try to keep humidity and temperature at the same level all year round. This can help climate equipment - air conditioning and an air humidifier, and for monitoring, special measuring instruments are needed - a thermometer and a hygrometer.

Lack of space

Lack of space for the laminate will be in case if the installation was immediately performed incorrectly, to be exact - without leaving compensating gaps, alike to the walls. In this case, there is simply no room for expanding the material when the parameters of its environment change.

Therefore, experienced masters know that around the perimeter of the room, where the laminate is laid, a gap of 10 ÷ 12 mm is always left between the coating and the walls, depending on the area of the room. In halls with a large area of coverage, where the skirting boards will look perfect and are able to close fairly large gaps, the walls recede even 20 ÷ 30 mm.

In rooms of a large area gaps can reach even 20 - 30 mm

By the way, for a laminate even special plinths are produced, having an elastic soft layer from below. This is necessary in order for the material to move smoothly to the required distance during expansion. Well, if there is no gap at all, then not only creak and crackling, but, possibly, significant deformation of the entire surface of the laminate will be provided.

Troubleshooting

If the laminate begins to creak, immediately it is necessary to check for gaps. This can be done by removing one of the skirting boards. If there are simply no gaps, or they are extremely small (less than 5 mm), you need to urgently begin to correct this violation during installation, otherwise the cover panels and their joints may be damaged and you will have to seriously invest in their replacement.

In order to correct the situation, you need to leave the gaps of the desired value. This is done as follows:

- They are removed from all the walls of the plinth.

- Next, the outer cover panels are dismantled. They measure the required distance, and the site is sawed off with a manual circular saw. Another option is to gently perform this action on the spot, using a special hand-held electric tool (something that resembles the work of a conventional grinder).

The second option is much more difficult to make - such a specialized tool is far from even for all masters, so it's better to use the first one.

- The dismantled trimmed panels must be installed in place, and then secure the skirting boards and the skirts.

It should be noted that sometimes the cause of creaking may be the plinth itself, if it is very strongly pressed against the laminate. To correct this moment, you need to raise the plinth slightly, or better - to fix a tape of thin polyethylene foam on the bottom part of it, or to get this trim element with the already existing soft bottom plane.

Low-quality laminate

Attempts to save money often lead to the acquisition of low-quality material for flooring. From such a laminate, you should not wait for long-term service, as in the design of its locks there may be inaccuracies in the manufacture, and this panel element is very often the cause of the creaking.

The logic of people saving on quality is hard to understand. Perhaps they are guided by the certainty that they will "carry", everything will turn out well and it will turn out. It is not excluded that they heard "good advice" from acquaintances who had once walked along this "slippery" path. But the logic here clearly limps - can not qualitative material of higher or first grade cost very cheap.

If even one of the layers of the laminate is made of low-grade materials, this can cause the entire coating to be stratified. Such material can in general react unpredictably not only to changes in temperature and humidity, but even to normal wet cleaning.

Video: the original replacement technique for a damaged laminated panel

Solution

To get rid of the squeak of poor-quality laminate, you can take all the above-described ways of repairing it, but the best option is to replace the cover completely. Therefore, choosing a decorative flooring for the floor, you need to carefully study its characteristics and be sure to find out the warranty period, which is set for him by the manufacturer. It is very important to purchase such materials in construction stores with a good reputation, which do not allow counterfeit goods on their shelves. And you can learn more about the publication of our portal dedicated to this issue.

New coating

A new laminated coating should adapt not only to its environment, but also to the substrate, as well as to the substrate. At first it can behave not quite as it would be desirable, and when walking along it, there may appear a creaking, rustling or clinking, slightly noticeable instability. Specialists say that this is quite normal, since laminated flooring should be closely adhered to the base surface. In the connecting locks, the tension that will occur with the installation of individual elements will be removed over time. The laminate flooring is floating, that is, it is not fixed to the base and to the walls, and it is necessary to find and occupy its stable place in a limited space.

The new cover at the beginning can also make creaks - this is not a "pathology"

If during installation, the process technology was fully followed and the recommendations of the manufacturer were not ignored, then after a certain time (usually not more than a month or two) the floors will settle down and cease to "swim" and creak. The stabilization period depends on the quality and material of the laminate, as well as on the substrate and the type of substrate that was used in the installation.

Of course, if nothing changes six months later, and the cover will still be "capricious," it's not at all the novelty of the laminate - it is worth looking for one of the above reasons.

- Some incompetent masters are sometimes advised to fight the creaking of a laminate using talc. However, real experts do not recommend this, as positive results can be achieved in a number, but it is easy to aggravate the problem. Having fallen into the locks, talc will only strengthen the squeaks with time.

- Laminate, which is fastened with glue, creaks much less often, since locks are protected from ingress of foreign particles into them, as well as possible friction between two panels. However, if the reason for the creaking is not locks, but an uneven hard base, you will not be able to get rid of unpleasant sounds until the surface of the base is aligned to the ideal.

- If the installation is carried out according to all the rules, high-quality laminate was laid, but it creaks because of fine grains of sand found in the locks or under the panels, that is, the sense for some time to suffer unpleasant sounds, as in time small particles of rubbish can be rubbed off, and the boards cease to creak and crackle. If this does not happen - you need to take measures - such as described above.

- In order not to become an unintentional culprit of a squeak, the owner should buy the laminate to be stored horizontally, on an even surface before installation.

- It is not recommended to install the newly purchased laminate - it should lie in the room, where it will be later laid, for two to four days, always with the original packaging opened - this is necessary for its acclimatization. It is especially important to take into account this requirement when purchasing material in the cold season, in order to avoid deformation of the panels.

Strict implementation of all the technological recommendations of the manufacturer of the chosen model of laminate coating is the main condition for the floor to maximize for a long time its beauty, comfort and quietness. Well and to get rid of the problems arising in the course of operation, it is necessary to undertake one of the ways of repair offered above.

Laminate offers a special installation system. This and other factors can lead to the creaking of the floor covering after laying.

It is not necessary to change all lamellas and organize new repairs. There are the most common problems that can cause an unpleasant defect. We will analyze them and ways of elimination.

Possible reasons

The creak can appear at different times after laying the floor covering. The main reasons are:

- There are so-called temporary creaking. Then the laminate ceases to make unpleasant sounds in a short time or after a change of seasons. This is caused by changes in temperature and humidity in the room. This is possible if, before laying, the floor covering was not left in the room to adapt to the conditions of future operation.

- Dusty ground or stones easy to recognize. In this case, the lamellas creak under their feet without shoes. The particles fall into the cracks and locks. Large gaps between the joints - the problem of laying not by technology or the drying of materials.

- Compensation clearances between the wall and the skirting are necessary to reduce the load on the cover panel. The creaking also occurs due to non-observance of the instruction. The mounting of the skirting boards should give little freedom for barely noticeable displacements of the laminate. When this is impossible, again there is a load and a characteristic sound.

- Uneven base Is a big problem and requires considerable effort to eliminate. Determine this cause will help the presence of pits in the finish screed, the depth of which is more than 3-4 mm. Savings on leveling lead to costs for repeated repairs. Because of the depressions the substrate is erased, slats bend, the level and geometry of the floor is disturbed.

- Base of old parquet, boards can also be the cause of the squeak. It is diagnosed by parsing part or all of the coverage. The method of elimination depends on the scale of the defects.

- Thick backing Over time, it is squeezed out due to loads and its softness. The changes are similar in an uneven ground situation.

- Low-quality laminate - one of the most expensive options. Unfair producers produce products from materials that are subject to low mechanical stresses and lose their properties in the first or second year of use.

To prevent the majority of problems, it is important to properly prepare the substrate, observe the laying technology and find the right materials. For example, when laying a laminate on an old parquet and a wooden floor, it is difficult to achieve a perfectly flat surface. Therefore, mount the plywood in the sheets. The main assistant in such works is the laser level, which makes it possible to notice even small deviations and irregularities.

How is carried out - look in this material.

All the nuances of repairing the wooden floor in Khrushchev are detailed here.

How can I fix this indiscriminately?

Dismantling of the entire floor covering is avoided. First of all, they establish the cause of the squeak. Sometimes methods without global parsing help:

- Increased humidity contributes to a change in the structure of the laminate. Porous surfaces become thicker, take up more space, and in joints there is an additional load in excess of the established rate. A simple way out is to measure the humidity and turn on the heating devices. The system of the warm floor is undesirable, it is better to heat the wall radiators. They will remove excess moisture from the air in a particular room and do not affect the coating itself. The temperature can be increased gradually, noting the changes in the panels.

- If the gaps between the wall and the extreme lamellae are absent, then they are enlarged by trimming. A suitable tool is needed. A great distance can sometimes be eliminated by placing a piece of cardboard between the wall and the panels. The parsing is not necessary at a dense adjoining a plinth. It is unscrewed, leaving a gap of about 10 mm. Between the wall and the adjacent lamellae, the distance can not be less than 7 mm in small rooms. The maximum clearance is 30 mm, if the room is spacious.

- Immediately after laying the laminate there is a gnash from the locking joints or joints. They can go through a couple of months after the start of operation. Otherwise, the reason should be looked for more carefully. Constant squeaking in the locks is eliminated by pouring a special sealant. Before this, you need to make sure that there is no dust and dirt particles in them. The product will additionally impart water resistance.

On how you can get rid of the creaking right after laying, look at the following video:

How to eliminate the scratching of the floor in the apartment with parsing?

Dismantling is an effective way to identify and eliminate the cause of long-playing squeaks. It is enough to make out a small area with lamellas:

- An uneven basis to exceptions does not apply. It is necessary to completely dismantle the flooring. Checking the height difference is done by the level tool. Approximate tolerances of depressions - 3-4 mm per 1 sq. M. m. The surface is sanded and poured with an equalizing screed if necessary. Finishing is also done by self-leveling mixtures. Again, check the differences and lay the laminate on technology with substrates and gaps.

- There is a cracked screed. This is a violation of the rules of its filling. It is necessary to replace the entire layer and cover with a new suitable primer.

- Garbage, sand, dust is removed after the analysis of the coating. In case of severe dirt, wipe the base with a damp cloth. Then use a powerful vacuum cleaner. The substitute is replaced with a new one, because it will be all in dust particles and sand. The inner side of the lamellas and the joints are treated with hardly damp cotton or microfiber material. The laminate is reinstalled, preventing the penetration of dust into the joints on the surface of the base.

- Poor-quality panels are to be recycled or used in places where the load and environmental impact are negligible. Changes in the layers make the laminate unfit, and it is impossible to fix the defects. Similarly come with a soft and thick substrate.

- Local analysis is appropriate if sounds appear on a specific site. The removed lamellas are installed back after stripping, puttying pits and priming the problem surface.

![]() Harmful advice - lubricate the joints and joints joints with oil-based products. This will eliminate the scratch for a while, but it will damage the laminate and the density of the panels fastening.

Harmful advice - lubricate the joints and joints joints with oil-based products. This will eliminate the scratch for a while, but it will damage the laminate and the density of the panels fastening.

All these methods are used after a thorough study of all related technologies or attract specialists.

In contact with

The laminate creaks what to do indiscriminately and how to eliminate different sounds when walking on a laminate. After laying the floor covering there can be an unpleasant problem - the laminate can creak. This may occur due to the fact that certain installation requirements have been violated during installation. If such a situation has arisen, you will have to understand why the laminate creaks. To eliminate the cause is best without parsing the floor, because, locks can be disposable and after the parsing it will be necessary to buy new material.

When a laminate creaks what to do is of interest to many, but not everyone thinks about the reasons for such problems. And there are many of them, for such reasons they include:

- Infringement of rules of preparation of the basis.

- Poor condition of the rough floor.

- Poor quality laminate.

- Violation of the rules for laying the floor.

- Low-quality choice of substrate or its complete absence.

If you do not comply with all the rules for laying the foundation, then the appearance of various shortcomings is quite expected phenomenon. Some of these problems can be eliminated indiscriminately, but sometimes a partial analysis or a complete analysis is required. When parsing the probability of damage to locks is high, as a result of which you will have to purchase additional material, and this will lead to an increase in the price of the floor from the laminate. In order not to puzzle over the question of creaking laminate what to do indiscriminately, it is necessary to strictly observe all the rules of laying.

Scrape a laminate with poor preparation of the base

Sometimes, the creak of a laminate can be a consequence of the fact that the original (rough) floor was in poor condition. If the cover was laid on the wooden floor , then it is necessary to check its condition before starting work. For this, the presence of cracks and rotten boards is checked. If the base is in an unsatisfactory state, then an alteration is necessary.

Before you start working on wood floors you need to rally. Rotten boards, even partially damaged, must be replaced. In the process it is necessary to do alignment.

Concrete screed can have 2 problems:

- Unevenness - in this case it is necessary to make the alignment.

- The old base can collapse. Most often, this option occurs if poor-quality concrete is taken.

If the base is old and begins to deteriorate, then it is better to replace it. But such works are very laborious and financially expensive. Correct the position will help plywood not less than 6 mm thick. It is put on the floor and fixed. Then lay the laminate. With the help of plywood, you can even out a wooden base.

Installation of plywood for laying laminate

If the disadvantages of the finished base from the laminate appeared due to a poor rough floor, then the entire construction will have to be disassembled. There will be no other way.

Eliminating the creaking of a laminate with an uneven base

If you clearly and correctly follow all the conditions for preparing the base for the laminate, then the likelihood of the appearance of shortcomings is reduced at times. All dependencies on the type of floor you need to level the floors. Unevenness affects the locks of the boards negatively. If the laminate creaks when walking, then the probability of uneven sex increases. This problem needs to be addressed.

The most effective method is to drill a small hole in the board. Next, the medical syringe is filled with PVA glue and this glue is injected into the hole. Filling is best done at a not very high speed until the glue comes out of the hole. If adhesive has got on the edge of the hole, then it must be removed. Then you need to leave the place of filling for 3-4 hours. At this time, it is better not to walk on the floor, so that the glue can seize.

Once the glue has seized it is necessary to seal the hole. To do this, apply sealants or mastics, putty or self-adhesive films. Sealants and mastics can have colored bases, and therefore you can choose the composition of the most suitable color for the laminate. To create the maximum effect of an intact board, you need to remove the excess of the composition with a cloth, and place the holes with fine emery paper, then polish with a cloth. For reliability, you can cover the board with a layer of colorless varnish.

Elimination of squeaking by the method of drilling laminate

Laminate scrape when laying a laminate on the rubbish

When the owners of the house begins to wonder what to do if the laminate is creaking, it is important to remember how the cleaning of the premises was conducted before the laying works.

After preparing the base, garbage often remains and if large debris is removed, then this attention is not paid to dust and small mote. And this step is vain. If there is sand under the laminate, then the creaking is quite possible. Therefore, before laying it is necessary to thoroughly vacuum the base and all cracks. If the slits are large, then they must be treated with fill formulations.

If it is determined that the laminate crunches because of debris, you can either dismantle the entire coating, or vacuum the laminate in places of contact with the wall. For this, it is necessary to remove the skirting board, and the coating can be slightly lifted in order to have a gap. In this gap, you need to insert the hose of the vacuum cleaner and try to remove the garbage.

It happens that the sounds from the coating pass through the entire surface area. In this case, the probability is high that the laminate was laid without observing the temperature gap. Such a gap must be left between the edgeboards and the coating, since the laminate has the property of linear expansion. If the gap is small, then under the action of expansion locks begin to creak.

Correction of such a defect does not take much time. To do this, remove the plinth, and increase the size of the slit with the help of a Bulgarian. Cover does not need to be removed.

Laminate scrape in the absence of a temperature gap

Scrape laminate from the substrate

Such a moment can also be. This is due to the fact that the wrong substrate was chosen. Laminate is a system of "floating" floor, this system needs a substrate. This element provides some softness to the coating and hides small unevennesses of the black floor. The substrate is selected depending on the material of manufacture and thickness. If the cover creaked, then, most likely, it's the wrong choice of substrate thickness.

Selecting the thickness is important to remember that the higher this parameter, the greater the gap between the floor and the board. A large gap can give a squeak. Therefore, the substrate needs to be chosen of a normal thickness.

The optimum thickness is 3-7 mm. The maximum parameter can be up to 10 mm. If the laminate creaks, what to do without parsing coverage will be interesting in this case. But everything here is bad for the hosts. In this case, it is necessary to remove the coating and replace the substrate with a thinner one. There are no other options for solving the problem.

The laminate locks screech

A very common cause of an unpleasant sound is the discrepancy or loose connection of locks. In case of divergence, a gap is formed, which sometimes can touch another board, resulting in a sound. With a loose lock, the same thing happens.

In this case, you can correct the position without parsing the surface. To solve the problem, glue composition is used, which is applied to the locks, and the boards try to move one another. The surface is left for a while to solidify the glue.

Sometimes, instead of glue, it makes sense to use a mounting foam. It is much better and faster grasps, as well as much better holds the panel. A big plus of foam is that it is enough to apply to the edges of the boards, due to the expansion it will reach the right, opposite edge itself.

However, when working with foam, use caution:

- The joints must be cleaned from dust.

- On the edge of the board are glued building scotch tape or paint tape. This is done so that the foam does not stain the surface of the boards.

- Foam is poured into the joint.

- After some time, the excess frozen foam is removed.

The surface of the joint can be dyed in order to avoid noticeable processing. Or a sealant or mastic of suitable color is used.

We glue the laminate locks

When choosing a laminate, it is important to remember that creaking can produce poor-quality coatings, so you need to choose high-quality material. In many cases, you can not do without dismantling the cover, so for such a case you need to pay attention to what locks the boards are equipped with.

On sale there is a laminate, which can be dismantled to several times. Of course, such coating options are more expensive, but it's better than buying a new material again anew.

In this material, 2 main questions on the subject of creaks are revealed: creaks of laminate what to do indiscriminately and why creaks of laminate. Now you know what causes can be behind the creaking of panels and how to eliminate them without disassembling the floor.

One of the unpleasant consequences, which can lead to incorrect laminate laying, is the creak of laminate panels when walking. And the question of what to do if the laminate creaks, occurs quite often.

In this article, we will analyze the main reasons why this script occurs, and consider how to fix it.

The reasons for creaking laminate

In fact, the reasons for creaking laminate after laying, can be a few:

- The most common reason is laying the laminate on an uneven base. If the laminate panels were mounted on an insufficiently level base, for example on a concrete floor with a difference in the plane, the creak of the laminate will appear quite soon.

The point here is: immediately after the unevenness, the lining is compensated for under the laminate. But over time, the lining is compressed, and the load on the laminate locks increases. It is under these conditions that a creak occurs.

- Another reason for the creaking is rubbish, sand or small pebbles under the laminate. This situation occurs if the substrate was not thoroughly cleaned beforehand.

As in the previous case, the first time the script does not show up, since it reliably protects the substrate. But it is worth the substrate to lose shape and elasticity - and you, immediately, start to hear a characteristic sound.

Note!

A characteristic sign that the cause of the creaking is sand or debris is the fact that the laminate creaks when walking barefoot, and not just when moving in shoes.

- Also, the laminate can creak if there is no necessary gap between the laminate and the plinth. And indeed, the plinth should not be tightly pressed to the laminate - otherwise the laminate, which is a sufficiently "movable" floor covering, will not be able to freely deform under loads, but will "rub" on the edge of the plinth.

- In addition to the gap between the plane of the laminate and the skirting, a gap of at least 10 mm between the edge of the laminate and the wall is also required.

The absence of this gap also leads to excessive compression of the laminate panels. As a consequence - increased load on locks and scratches under load.

- Well, and at last - one more reason. Even on a level surface, laminate, laid by all the rules will creak if it is a poor-quality laminate.

That's why you should not buy the cheapest laminate models (although their price seems rather seductive).

Otherwise, we will no longer have to look for the cause of the creaking, but to find out why the laminate is cracking and where the cracks come from.

Fighting the creaking of laminate

Laminate flooring

When we found out why the laminate creaks on the floor - it's time to move on to eliminating the creaking.

If the laminate makes a creaking because of the lack of a gap between it and the wall - the problem is solved most easily.

To eliminate the squeak, proceed as follows:

- We dismantle the plinth closing the gap between the laminate and the wall.

- We disassemble the laminate panels adjoining the wall (how to disassemble and assemble the laminate, you can study using video instructions).

- With the help of a disc or saber saw, we cut the edges of the panels in such a way that the clearance is 10 mm.

- We mount the panels in place.

Advice!

In this case, it is not superfluous to check whether the plinth is also involved in the skirting. If you think that the gap between the baseboard and the plane of the laminate is not enough - it is better to fix the plinth slightly higher.

How to eliminate the creaking of the laminate in this situation, we hope, figured out. Moreover, it is easy to do this even with your own hands, without attracting the masters for laying the laminate.

But what if the gap between the laminate and the wall is sufficient, and the laminate still creaks?

Most likely - it's either in the uneven floor, or in the garbage, as we noted earlier.

Cleaning the floor under the laminate

If the reason for the squeak, in your opinion, is dust and sand under the laminate, the best way to get rid of the creaking is to remove dust and sand.

Of course, if you have a very high-quality laminate flooring, then you can just wait - eventually the grains will be rubbed between the concrete base and the laminate panels, and the creak will go away. But it's better not to take risks, because laminate flooring can seriously deteriorate from the inside.

Cleaning the floor under the laminate is done like this:

- We dismantle the laminate throughout the room. If the laminate is creaking only in one place - you can confine, so to speak, "local destruction".

- We shoot. After dedusting its base, by the way, it's better to replace it - rather than laying worn out on the old place.

- The substrate under the laminate is cleaned with a vacuum cleaner. In some cases, you can first walk on the floor with a damp cloth.

- Before laying the laminate back, the locks and the underside of the panels are also wiped with a damp, clean rag.

By the way, before you remove the scratch of the laminate in this way, you can experience a compromise solution: in the gap between the wall and the laminate under the creaking section, we put a sheet of cardboard. Should help - but, the truth, only in the event that creaks a site near to a wall.

Floor leveling

But what if the laminate creaks because of mounting on an uneven floor?

Here it is necessary to prepare for major repair work.

The instruction in this case is as follows:

- We dismantle the laminate, remove the substrate from the base.

- On the concrete foundation we lay the leveling cement-sand screed.

- Over the dried screed, we apply a self-leveling coating.

- Wooden base with a wreath, and if the barking did not help - we even out, spreading over it sheets of thick plywood or chipboard.

- We check the plane of the obtained base by means of a level.

- As an insurance - dedusting the base, using a powerful vacuum cleaner.

- We lay on the substrate substrate.

- We mount the laminate panels, paying attention to the fact that construction dust does not get into the locks.

As a rule, after all this, the creaking of the laminate "goes away" forever.

We hope that these tips will be useful to you, because you can implement them without even having special skills. So if you or your friends have a laminate creaking - what to do, you already know!