It is a facade covering of the walls of a building, consisting of panels laid on a sheathing.

The range of panels is varied: they can be made of various materials and have a variety of shapes, textures and colors.

Installation of siding is quite simple, its operational period can reach fifty years.

In this article you will learn how you can cover the outside of a house other than siding.

The popularity of siding cladding is primarily associated with its characteristics, which are inherent in this type of material. Houses covered with siding have an aesthetically attractive and very neat appearance.

Distinctive characteristics of siding are:

- Durability of the material;

- a large assortment;

- variety of materials (wood, vinyl, metal);

- ease of care;

- the presence of an air gap between the wall of the house and the cladding prevents the formation of mold or mildew;

- quite easy to install;

- UV resistant;

- frost-resistant;

- waterproof;

- has resistance to mechanical damage.

quite fragile at subzero temperatures, flammable and quite flammable.

Requires care during installation, since even with a slight bend the material cannot be restored: the panel must be replaced.

short-lived.

Despite the presence of shortcomings, siding still has much more advantages, which determines the rapidly growing interest in this type of cladding.

Siding analogues

In addition to siding panels, you can also clad your house with other materials that are no less common on the construction market.

These include:

- decorative plaster;

- porcelain stoneware;

- sandwich panels;

- natural and artificial stone;

- tree;

- brick.

Each house cladding option has its own advantages and disadvantages. Before choosing a cladding option, you should be guided not only by the aesthetic appeal of the material, but also by its technical characteristics.

Decorative plaster

Decorative plaster is a budget material, so it is widely used.

Plaster can be non-aqueous or water-free. Popular is mineral plaster, which is made on the basis of cement and additional components.

Decorative plaster can be polymer, silicone or silicate.

ATTENTION!

The material is presented in the form of a dry mixture, and for application this mixture must be diluted with water. Various colors and admixtures can be added to the plaster mixture to achieve the desired color and effect.

The advantages of decorative plaster are:

- no toxic fumes;

- high adhesive ability;

- long shelf life of the dry mixture;

- no special care required;

- ease of manufacture and application;

- does not absorb dirt;

- a wide variety of colors and textures;

- the vapor permeability of the material ensures a comfortable microclimate in the room;

- resistance to temperature fluctuations;

- good sound insulation and heat insulation properties.

The plaster perfectly withstands atmospheric and mechanical influences.

Decorative plaster has disadvantages, but they are not decisive when choosing cladding:

- in the absence of a reinforcing mesh, the plaster is susceptible to chips and cracks;

- repair work must be carried out at temperatures above +5° C;

- the cost of decorative plaster is much higher than usual.

When using decorative plaster, you should follow the recommendations for its application.

When creating a textured relief, professionalism and a lot of time are required.

Decorative plaster

Porcelain tiles

Porcelain tile is a compressed and fired clay mixture with the addition of quartz, feldspar and natural-based dyes.

The main quality of the material is strength.

Porcelain tiles are made in the form of slabs of various thicknesses, textures and colors. It has properties that are not inferior to natural stone.

The main indicator of the color, structure and texture of a material is its composition, which includes manganese, chromium, iron, zirconium or cobalt salt. The surface can be matte, polished, embossed, polished or glazed.

The features of porcelain stoneware are:

- high strength;

- durability;

- independence from weather changes;

- environmental friendliness;

- no fading;

- soundproofing;

- thermal insulation;

- fire safety and protection of walls from fire;

- resistance to microorganisms;

- ease of installation;

- a ventilated façade ensures a comfortable microclimate.

The aesthetic appearance of a porcelain stoneware building is ensured by the textured coloring of the material., it is easy to maintain and simple to repair.

The disadvantages of porcelain stoneware are the heavy weight of the slabs, which requires a solid foundation for the building and load-bearing walls and high cost.

Porcelain tiles

Sandwich panels

Sandwich panels are a thin aluminum sheet with a thermal insulation layer. They are used for finishing office, administrative, sports and socially significant facilities.

The panels are available in glossy, matte, lacquered color coatings, and also treated with powder or polymer mixtures.

The advantages of sandwich panels are:

- environmental friendliness;

- soundproofing;

- good thermal protection;

- a light weight;

- resistance to corrosion and rotting;

- ease of installation;

- durability;

- low cost.

Sandwich panels are easy to install and the structure itself is not heavy, which does not require additional reinforcement of the walls.

- the possibility of having fire hazardous insulation in the panels;

- limited assortment;

- During installation, the joint areas must be covered with a special sealing tape.

CAREFULLY!

The installation of sandwich panels should be entrusted to professionals, since minor errors can reduce the thermal insulation qualities of the cladding.

Particular attention should be paid to the places where the slabs are connected.

Sandwich panels

Natural and artificial stone

Facade stone can be natural, which is classified by species, and artificial, which is an imitation of natural rock or organic mineral.

Natural stone

There are several types of stone cladding for masonry:

- “from the die”;

- "Castle";

- "Plateau";

- "Shahriar";

- "Assol";

- "Rondo".

The texture of natural stone can be granite, marble, limestone, slate, sand.

The advantage of natural stone cladding is durability and strength. The material is environmentally friendly, frost-resistant and fireproof.

Natural stone cladding requires its treatment with protective agents to prevent the formation of salts on its surface.

The disadvantage of natural stone cladding is its cost and heaviness.

Natural stone

Fake diamond

It is produced by mixing polymer and mineral components, which are poured into molds and hardened under a brick press.

Happens:

- clinker;

- concrete;

- architectural;

- polymer sand;

- resin based;

- ceramic.

Artificial stone has similar characteristics to natural material, but is much lighter.

Compared to natural stone, the resistance of artificial stone to external influences is much less, and therefore the service life is reduced.

Fake diamond

Cassette facade

Cassette facades are cladding material in the form of slabs. Cassettes can be composite or metal. The design of the structure is worked out by computer, based on the shape, size of the building and the material of the cassettes.

Small cassettes are made from aluminum. For large forms, composite materials are used.

Cassettes differ in color, size and texture.

Positive characteristics of a cassette facade:

- strength;

- resistance to atmospheric and mechanical influences;

- resistant to corrosion;

- ease of construction;

A high degree of decorativeness provides individuality to any building equipped with cassettes.

A significant disadvantage of this type of façade improvement is its high cost.

Cassette facade

Tree

Wood is used as cladding to give the house a natural look.

Modern types of cladding can be used to imitate wood:

- lining;

- block house;

- facade board (planken);

- imitation timber.

The lining is a solid board. Has different quality classes. It is lightweight, accessible and low cost.

Block house is a high-strength material that is a covering in the form of timber. Classified by color and texture.

Facade board is a profile material resembling siding panels. The peculiarity of the installation is the technology of the permissible distance between the boards to ensure ventilation.

Imitation timber looks like a board. Mounted using tongue-and-groove technology.

The advantages of wood are environmental friendliness, non-toxicity and good thermal insulation and sound insulation properties.

A significant disadvantage of wood is its susceptibility to rotting and fragility. However, with regular treatment of a wooden facade, its service life increases significantly.

Brick

The brickwork that is used to clad the building is designed to give the building strength and protect the internal load-bearing wall.

The structure of facing brick can be:

- ceramic;

- clinker;

- silicate;

- hyper-hyped.

Based on the front surface, bricks are classified into:

- smooth;

- raised;

- glazed;

- engobed.

Brickwork can be of different colors, and the material itself differs not only in texture and composition, but also in color.

The main advantages of brick cladding are strength, resistance to external influences, and protection of the house.

In addition, the brick has:

- fire resistance;

- environmental friendliness;

- frost resistance and low thermal conductivity.

The disadvantage of brick cladding is its significant weight. In addition, the price of bricks is quite high.

Conclusion

Thus, quite a lot of alternative cladding options, in addition to siding panels, can be used when finishing the facade. You can determine what exactly is suitable in a particular case, based on the price, characteristics of the material, the ability to install it yourself, as well as in accordance with design ideas.

Useful video

In this video we will look at all analogues of siding:

In contact with

External wall cladding is one of the final stages of building a frame house. And here the choice of material is of great importance: the microclimate in the premises, the mechanical strength of the walls, and the reliability of protection from moisture and cold depend on it. In addition, the cladding serves as the basis for finishing materials, and in some cases acts as a finishing coating and is responsible for the aesthetic appearance of the building.

The cladding gives the building frame a certain rigidity and takes on part of the load. This means that one of the main criteria is the mechanical strength of the material in bending and compression, and the absence of shrinkage during operation. The walls must retain their original shape for years, regardless of environmental conditions. In addition, the cladding must be resistant to moisture, sudden temperature changes, and the effects of microorganisms.

Next, you need to pay attention to the ease of installation of the material and its flexibility during processing. If you plan to sheathe it yourself, this aspect is of great importance, because it determines how much effort and time the work will require. The material should be easy to cut and drill, but at the same time maintain density in cuts, not crumble, not crack. And, of course, it must be durable so that you don’t have to change the skin every 10-15 years.

Material selection

There are several types of materials that more or less meet these requirements: moisture-resistant plywood, fiberboard, OSB, edged boards, fiberboard. They have similar characteristics and are widely used in frame construction. To make a choice, it is worth familiarizing yourself with the main properties and features of each of them.

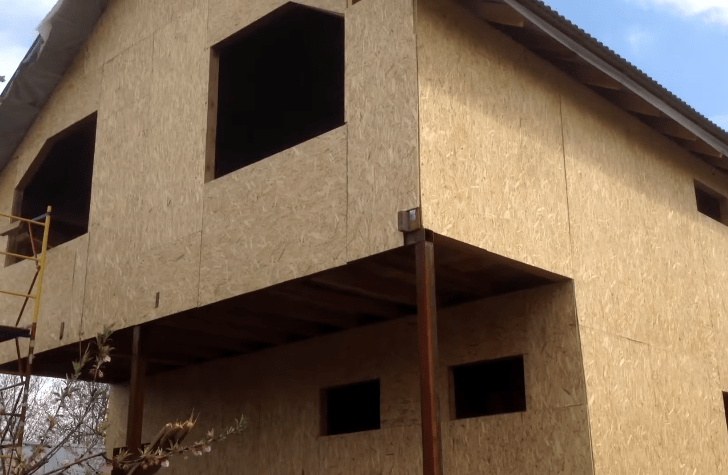

Oriented Strand Boards (OSB)

OSB panels are rightfully one of the most popular materials when arranging frame structures. They consist of layers of laminated wood chips and chips, with the fibers in the outer layers arranged longitudinally and transversely in the inside. Synthetic resins and wax are used to hold the chips together, giving the finished boards water-repellent properties.

Standard production involves the production of these slabs in several categories:

- OSB-1 is intended exclusively for interior decoration of dry rooms with reduced mechanical loads;

- OSB-2 is used when installing load-bearing structures in rooms with low humidity;

- OSB-3 is a moisture-resistant board of increased rigidity used for the installation of load-bearing structures indoors and outdoors.

In terms of the quality-functionality-price ratio, OSB-3 is the most optimal, and this material is widely used in private construction for wall cladding, the manufacture of load-bearing partitions, and reusable formwork when pouring concrete structures. The slabs lend themselves well to grinding, cutting, drilling, and hold nails tightly even at a distance of 6 mm from the edge. Such cladding can simultaneously serve as a decorative covering for walls; you just need to treat it with waterproof varnish or paint it.

Advantages of OSB:

- the dense structure prevents delamination and splitting of the material during processing and during operation;

- the plates have elasticity and high strength, excellent resistance to vibrations, compression loads, and various deformations;

- the material is resistant to weathering and temperature changes;

- OSB is resistant to microorganisms; insects and rodents do not like it.

Flaws:

- very low vapor permeability;

- flammability;

- content of toxic compounds (phenol and formaldehyde).

Main characteristics

Prices for OSB (oriented strand boards)

OSB (oriented strand board)

Cement particle boards (CSP)

This material is a compressed mass of M500 cement and wood shavings (usually softwood). A standard slab has three layers: the outer ones are made of small chips, the inner one is made of large ones. In addition to the main components, the composition contains hydration additives, the mass fraction of which does not exceed 3%. DSP is characterized by resistance to moisture, high strength, and long service life. The slabs are widely used in private and industrial construction, for indoor and outdoor work.

When covering a frame, such slabs serve as an excellent basis for cladding, decorative plaster, and painting, since they form a perfectly flat and smooth surface. The material can withstand 50 cycles of complete freezing and thawing without losing its characteristics; subsequently, the strength of the slabs decreases by about 10%. Among wood-based panel materials, DSP is a leader in terms of environmental and technical indicators.

Advantages:

- very low hygroscopicity;

- resistance to mold and other microorganisms;

- DSP are not damaged by insects and rodents;

- the material does not emit toxic substances;

- low thermal conductivity;

- Fire safety.

Flaws:

- mechanical processing of plates requires significant effort;

- DSP is heavy compared to other materials;

- When cutting and drilling slabs, a lot of fine dust is generated, so you need to work in a respirator;

- high price.

Specifications

Fiberboard (Fiberboard)

The material is sheets of compressed shavings, usually coniferous. During the pressing process, the raw materials are highly heated, which makes it possible to achieve maximum density without the use of adhesives. Thanks to this, fiberboard is an environmentally friendly material, and therefore suitable for both outdoor use and finishing of residential premises. The shavings contain natural resin, which acts as an antiseptic and protects the slabs from mold.

In terms of strength, fiberboard is noticeably inferior to natural lining and OSB, but it surpasses them in heat and sound insulation properties.

Windproof board "Beltermo"

Now on the construction market, fiberboards are represented by insulating boards of several well-known brands, the most popular of which are Beltermo and Izoplat. For cladding a frame house, slabs with a thickness of at least 25 mm are used; thinner sheets are used indoors.

Advantages:

- light weight;

- low thermal conductivity;

- ease of installation;

- the material does not delaminate or crumble;

- high vapor permeability;

- resistance to moisture and microorganisms;

- absence of harmful substances in the composition.

Flaws:

- high price;

- a long stay without decorative finishing causes slight deformation of the sheets;

- The outer lining of fiberboard requires spacer jibs in the frame or rigid inner lining.

Specifications

Prices for fibreboards (fibreboards)

Fiberboard (Fiberboard)

Gypsum fiber sheets (GVL)

GVL consists of pressed gypsum reinforced with cellulose fibers. Due to its high strength, the material is suitable for creating load-bearing surfaces, therefore it is widely used in frame construction. It differs from plasterboard in its greater density, uniformity, and absence of a cardboard shell. In terms of frost resistance, sound insulation properties, as well as resistance to moisture and combustion, gypsum fiber boards are also several times higher than gypsum boards.

GVL installation is carried out using frame and frameless methods. For external wall cladding, the first option is used, where the sheets are fastened to the load-bearing posts using self-tapping screws. The material is easy to cut and drill, and, despite its heavy weight, is quite convenient to install. This cladding serves as an excellent basis for finishing with tiles and decorative plaster.

Advantages:

- low hygroscopicity;

- vapor permeability;

- absence of toxic compounds;

- fire safety;

- high heat and sound insulation properties.

Flaws:

- lack of ductility and fragility when bending the sheet;

- heavy weight.

Specifications

Plywood

Plywood is made by gluing together thin sheets of veneer from various types of wood (most often coniferous and birch). The sheets are laid perpendicular to each other relative to the location of the fibers, which helps to increase the mechanical strength of the material and increases resistance to deformation. For the outer cladding of frame walls, plywood with increased moisture resistance is used, which is marked FSF. The thickness of the sheets should be from 9-10 mm; thinner material will not provide the required rigidity to the frame.

The grade of plywood is not particularly important for sheathing, and you can use the cheapest unsanded 4/4 grade boards.

From the outside, all defects will be hidden under the curtain wall, so there is no point in overpaying. If the cladding technology is followed, the plywood covering will serve for years without losing its qualities.

Advantages:

- high bending and compressive strength;

- moisture resistance;

- wear resistance;

- ease of processing and installation;

- frost resistance.

Flaws:

- flammability;

- content of formaldehyde resins;

- tendency to chipping.

Specifications

Plywood prices

Edged board

Using edged boards for sheathing is the most economical option. Wood is an environmentally friendly material, affordable, and easy to install. Boards can be filled not only horizontally, but also at an angle of 45-60 degrees. To save material, boards can be fastened in increments of up to 30 cm, although more often the sheathing is made continuous. This design perfectly strengthens the frame and is a ready-made base for a ventilated façade.

In order for the cladding to be reliable, boards should be chosen with a thickness of at least 25 mm; they can be tongue-and-groove for greater joint density. You cannot use raw lumber: during the drying process, the wood will begin to warp, and deformations of the finishing coating may appear.

Advantages:

- wood does not emit harmful substances and has excellent vapor permeability;

- boards are easy to process;

- the work does not require large financial costs.

Flaws:

- flammability of the material;

- wood is susceptible to damage by insects and microorganisms;

- Fitting and fastening elements takes a lot of time.

Prices for edged boards

Exterior cladding technology

Installation of slabs on a finished frame is carried out using the same technology, regardless of the type of material. Simultaneously with the sheathing, vapor barrier and wall insulation are carried out, and finishing can be done immediately upon completion of construction or after some time. Let's look at the installation technology using the example of covering a frame with OSB boards.

Sheathing can be done in two ways - with and without lathing. In the first case, the vapor barrier layer is located between the frame and the OSB, in the second - on top of the sheathing. The option with lathing is used in cases where OSB acts as a basis for plastering, painting or tiling; the second method is used, as a rule, when installing a ventilated facade. Otherwise there are no significant differences.

Step 1. Start covering from the very corner. The first sheet of OSB is applied to the frame posts so that the bottom edge completely covers the bottom trim of the house. Be sure to check the horizontal level. It is also recommended to install the slab itself horizontally rather than vertically - this provides the structure with greater rigidity. To fasten the material, galvanized self-tapping screws with a length of at least 50 mm are used. It is necessary to retreat about 10 mm from the edge of the OSB, the fastening step along the perimeter of the sheet is 15 cm, in the center - 30 cm.

Advice. To firmly fix the slabs, the length of the hardware must exceed the thickness of the OSB by at least 2.5 times. If the self-tapping screw enters the frame beam less than 30 mm, under the influence of loads the sheathing will begin to tear away from the supporting base.

Step 2. The next plate is installed next to the first, leaving a gap of 2-3 mm for thermal expansion. In the same way, set the horizontal level and screw the casing to the frame guides. The joints of the plates must be in the middle of the rack, only in this case the fastening will be as reliable as possible. Fix the remaining slabs in a circle, leaving open areas for doorways.

Step 3. The second row of sheathing must be installed with ligation of vertical seams. The same gap of 2-3 mm is maintained between the lower and upper plates. When sheathing openings, you should use whole sheets, not scraps - the fewer joints, the more airtight the sheathing. Cutouts in the sheets are made with a jigsaw or a circular saw, having previously made markings accurate to the millimeter. The edges of the cuts after installing the slab should perfectly coincide with the lines of the openings.

Step 4. The top plates are installed so as to completely cover the top trim. If the house has two floors, the interfloor piping should be closed in the middle of the slab - under no circumstances should OSB be joined on this line.

Gallery 1. An example of the construction of a one-story frame house finished with OSB boards

Gallery 2. Sheathing a two-story frame house with OSB boards. Example

Step 5. After completing the installation, a windproof membrane is attached over the casing. Its sheets are stretched horizontally and fixed with staplers to the OSB. At the joints, the film is overlapped and taped. The material should not be pulled too tight, but there should be no sagging.

Step 6. Next, the sheathing slats are stuffed for finishing in increments of 50-60 cm. The slats must first be treated with a protective compound and dried. After this, you can begin installing siding, lining or other decorative covering for the house.

On a note! If you plan to paint the facade from OSB, then the membrane, accordingly, is installed only on the inside of the house.

With this method of cladding, the insulation is placed on the inside of the walls in the cells of the frame and covered with a vapor barrier film. Slabs for interior decoration, for example, plasterboard or the same OSB, are sewn on top of the vapor barrier.

Video - How to sheathe the outside of a frame house

Wood is a durable and beautiful building material that, with proper care, will last for many decades. At the same time, wood is quite an expensive material, especially when it comes to various types of well-dried timber, so the walls are made thinner, and heat loss is reduced with additional insulation and external cladding. We will talk about the requirements for cladding material, and also compare different materials to determine which one is better suited for a wooden house. In addition, we recommend organizing a ventilation system (ventilated façade) for any cladding, because this approach extends the service life of the wood and reduces the requirements for cladding materials. We will try to answer the most important question - what is the best way to sheathe the outside of a wooden house so that it is cheap and beautiful.

Requirements for cladding materials

Any cladding material must meet the following requirements:

- fire resistance;

- resistance to precipitation;

- resistance to temperature changes;

- UV resistance;

- ease of installation;

- low price.

Fire resistance– one of the most important parameters for cladding material (cladding). It is clear that if there is a strong fire near the house, then any material will catch fire, but it should be very difficult to set it on fire with a match and paper, or even pouring gasoline on it. In addition, the cladding should not be afraid of rain or snow, that is, precipitation should not lead to its destruction. Another condition is resistance to temperature changes. If the facing material strongly absorbs water, then when the temperature drops to negative values, the water in the outer layers will freeze and tear the material. UV resistance protects the cladding from discoloration under the influence of sunlight - the more resistant the material, the less it fades over time. Equally important are parameters such as ease of installation and cost of material. After all, the use of difficult-to-install material increases overall costs, because it is necessary to use special technologies or equipment, to which not everyone has access.

Sheathing materials

Here is a list of the most popular materials for cladding wooden houses:

- various thermal panels;

- reinforcing mesh and plaster;

- PVC siding;

- metal siding;

- wood-cellulose siding;

- fiber cement siding and panels;

- fake diamond;

- block house;

- board;

- waterproof OSB (Oriented Strand Board) and plywood.

Thermal panels- the simplest finishing option, because they combine polystyrene or foam insulation and various external finishes. The most popular panels are those with a brick finish. However, to install them, you must first install the bars of the ventilated facade. Plaster with reinforcing mesh can be applied to any hard surface, so it is often used if a wooden house is insulated with foam plastic or highly compressed mineral wool. This finishing scheme is very popular - mesh + glue + bark beetle plaster.

All types of siding are mounted on an insulated ventilated facade with wooden bars or metal profiles. Siding is the simplest method of exterior finishing of a room, the only difference is the cost of materials. The advantage of siding is that you can use both classic rectangular panels and “log-like” panels. Fiber cement panels are used if it is necessary to increase the fire resistance of a house, because this material is ten times more difficult to set on fire than even timber treated with pyrophobic impregnation. After finishing the house with fiber cement boards, the cladding must be painted with waterproof paints. Artificial stone is tried on for finishing a ventilated facade. To install it, the facade must be covered with a hard material, such as fiber cement board, OSB or plywood. Then the artificial stone is glued to the facade, using the same reinforcing mesh as for plaster.

Block house, that is, a board whose outer part imitates a rounded log. Covering a wooden house with a block house allows you to restore its exterior to some extent, demonstrating to everyone the aesthetic taste of the owner and his desire to live in a house made of natural materials. A house covered with a block house must be regularly treated with antiseptics and impregnations. Read about how to choose antiseptics and impregnations in this article (I think it’s called how to choose impregnations or antiseptics, I don’t remember exactly). The advantage of a block house over other materials is its very high vapor permeability, therefore the requirements for façade ventilation are much lower. Another wood material is carriage board. It is cheaper than a block house and creates a more primitive exterior of the house, but has all the performance qualities of a block house.

OSB and plywood used in three cases:

- when it is necessary to create a hard, rigid surface for applying plaster;

- for cladding outbuildings;

- for cladding for painting.

Waterproof plywood and OSB have all the disadvantages and advantages of boards and block houses, however, they are much cheaper. Therefore, they are used for cladding inexpensive houses and outbuildings where there are no high requirements for the exterior.

Cost of finishing materials for cladding a wooden house

Below we have provided average cost data posted on the websites of stores selling finishing materials:

- Russian-made thermal panels, 60–80 mm thick, panel size 100x68 cm (length and width), cost per panel 1000–2300 rubles, cost per m² 1600–3400 rubles.

- Reinforcing mesh for plaster (glue + bark beetle plaster) will cost 20–50 rubles per m² of mesh. The cost of one bag of dry plaster (20 kg) is 150–300 rubles, with a consumption rate of 2–4 kg m². That is, one bag is enough for 5–10 square meters. The cost of one bag of bark beetle plaster (20–25 kg) is 150–500 rubles, with a consumption rate of 3–6 kg per m². That is, one bag is enough for 3–8 m².

- PVC siding - price per m² excluding the cost of lathing is 100–300 rubles.

- Metal siding - price per m² excluding the cost of sheathing is 200–700 rubles.

- Wood-cellulose siding - price per m² excluding the cost of lathing is 60–200 rubles.

- Fiber cement siding and panels – price per m² is 1–3 thousand rubles.

- Artificial stone - price per m² 600–3000 rubles.

- Block house made of dry boards - price per m² 200–600 rubles.

- Boards (lining) made of coniferous and deciduous wood 150–250 rubles per m², from valuable wood 300–700 rubles per m².

- Moisture-resistant plywood and OSB 12–16 mm thick price per m² 150–250 rubles.

Conclusion

The correct choice of material for finishing a wooden house will allow you to achieve the desired effect at minimal cost. After all, the cladding is not only a decorative element, but also protects the insulation and walls from external influences. By choosing one or another coating, you can dramatically change the exterior of the house, both emphasizing that it is made of wood and harmoniously coordinating it with other buildings in the area.

The wooden house has been a traditional home in Scandinavia and Rus' for centuries, but recently it has come back into fashion again. A wooden structure is environmentally friendly, it can be built faster than a stone structure, and it is not stuffy or damp. Its disadvantages are low fire resistance and susceptibility to fungus. Shrinkage of up to 6% may occur after construction. During this period, especially if the house was not built perfectly, it is worth thinking about additional cladding.

Video - how to sheathe a wooden house

What does exterior cladding of a house provide?

- Increased fire resistance, pest and chemical resistance

- Improving the appearance of the building

- Insulation and protection from drafts

To achieve these conditions, refractory materials with low thermal conductivity and gyroscopicity are usually chosen. For insulation, mineral wool and polystyrene foam are used; decorative materials include wooden lining, siding, heat-insulating plaster, block house and even facade brick.

Insulation

It is especially necessary to insulate a house in the northern regions; in the south, you can often get by with only sheathing; it also insulates the house a little.

The main advantage of foam insulation is its price and ease of use. There are many more disadvantages. The vapor permeability of this material is 10 times lower than that of mineral wool, so when using polystyrene foam you need to carefully consider the ventilation system. The wood underneath may begin to rot; the material “does not breathe.” These savings can add up to much higher costs in a few years.

Mineral wool is a more common and environmentally friendly material. They insulate a wooden house using a frame scheme:

- Fill up the voids between the beams.

- Lay out a vapor barrier layer (roofing felt, foil, plastic film).

- They make a frame - they nail 50 by 50 mm bars to the walls every 0.4-0.6 m.

- Lay mineral wool, filling all voids.

- Lay another layer of film to insulate from wind and water.

- The house is clad on top.

Additionally, there is no need to attach the mineral wool to the frame; it will stick between the layers on its own.

Exterior wood cladding of a house

Wooden cladding includes lining, imitation timber and block house. The materials differ in price and appearance, all three are environmentally friendly, perfectly absorb street noise, insulate the room and look natural. There is also the option of planken or “finish quarter” cladding. But these materials do not have spikes, so gaps may appear during installation.

They should be used for interior work. The most expensive and beautiful block house, it easily withstands temperature changes, and from the outside it looks like a rounded log. Lining is a common choice in the mass market; it looks a little simpler. The cladding is made from larch, oak or pine wood. In order for wood paneling to serve for many years, it must be impregnated with a fire-resistant compound, varnished and painted.

The cladding technology is the same for all three finishing materials. The wood is nailed, glued or attached to hooks. You need to sheathe from bottom to top. The first board is attached to the frame, the second is put with a groove on the ridge of the first. Using wooden wedges, press the top to the bottom along the edges and middle, then nail it down, and remove the wedges. This way they reach the roof. Work can only be carried out in dry weather.

Siding can be made of metal or vinyl. The first is less durable, but it is lighter than metal and successfully resists corrosion. It does not need to be painted; the dye is added to the composition already at the manufacturing stage. The second quickly cools down and heats up in the sun, when hit, dents and scratches appear on it, then it can begin to corrode.

Installation begins from the corners. Attach with self-tapping screws to the sheathing, from the middle of the panel to its edges. You need to leave a gap of 5-7 mm between the nail head and the siding, since the material expands when heated. When installing siding in cold weather, the gap should reach 10 mm. The elements are connected with an overlap of 2 cm.

Tiles are rarely used for walls; they are usually used to decorate the foundation and corners of a house. The tiles are fastened from the bottom corner of the sheathing and then moved horizontally. The row is fixed with self-tapping screws. The next row is inserted into the locks of the first tiles, then again held in place with self-tapping screws. Tiles can also be glued using special compounds.

Corners can be overlapped or butted. When fastening with an overlap, the lathing should be at the level of the wall tiles; installation is carried out by extending 30 mm onto the tiles.

Facing with stone and facade bricks

Finishing with stone greatly weighs down the house; a weak foundation may not be able to withstand the additional load. At the same time, the house becomes warmer and is not subject to combustion. Artificial stone is much lighter and suitable for any type of foundation. Work is carried out only after the house has completely settled, no earlier than a year after construction. The gap between the brick and the wall should be at least 5 cm.

As we can see, there are many types of decorative finishes. The choice should be made based on your own budget and climatic conditions. Perhaps your house does not require additional finishing or insulation at all, and it is enough to simply paint it.

Wooden houses are very popular among the population, because they are distinguished by beauty, environmental friendliness and unique elegance. Inside, such a home creates a warm and cozy atmosphere. If you properly decorate the inside of such a house, then for many years several generations of residents will be able to live in comfort and beauty. Photos of examples of interior decoration of houses can be viewed in the presented selection.

When choosing materials for the interior decoration of a wooden house, you should pay attention to many factors. Houses that are occupied only in the summer and all-season buildings require different materials. If the house is being built for living only in the warm months, then there is no need for any additional insulating materials. In this case, varnish, stain or special tinting is sufficient to process the wood.

A wooden house is good because it maintains its unique microclimate. Materials used for interior decoration should not negatively affect temperature and humidity. The optimal finish for such a house should match the composition of wood, that is, be safe and environmentally friendly.

Log in the interior of a wooden house

Log in the interior of a wooden house The coefficients of the main material of the house and the finishing should also be taken into account, since temperature differences and humidity can expand or contract materials. It is not advisable to build damp rooms with strong heating from coniferous wood. In such a microclimate, resin actively begins to be released. When decorating different rooms in the house, you should take into account the specific features of the room, but maintain the overall theme.

Features of using drywall

It is recommended to use plasterboard as a finishing if you need to eliminate any defects: smooth out uneven walls or close communications. Interior partitions are made from plasterboard, and ceilings are also finished with it. If you need to decorate a room with high humidity, it is recommended to use moisture-resistant materials, and if the temperature is high, then fire-resistant coatings will be required. A timber sheathing is usually installed under the drywall. A metal profile structure is not suitable for wooden houses.

Lining

Although lining has been used in construction for a long time, new, modern types of this material have now appeared. The photo shows that it looks very aesthetically pleasing and is easy to install. The slats are connected to each other using special fasteners, allowing you to create a perfectly flat, beautiful surface. Cladding with clapboard is suitable for a bathroom, kitchen, veranda, that is, for rooms where it is always damp.

The lining has the following advantages:

- environmental friendliness;

- ease of installation;

- a wide palette of all kinds of colors and shades;

- large selection of varieties.

The disadvantages of this material include its too high price and the fact that it requires careful maintenance. Before you start covering the walls with clapboard, you need to install a timber sheathing. The slats are thoroughly cleaned and dried beforehand. If there are stains, they are removed with ammonia or hydrogen peroxide. The final stage is coating the lining with varnish, sanding and another varnishing.

Block house

Recently, a new type of lining - block house - has gained great popularity all over the world. The use of this material for cladding the walls of a wooden house allows you to preserve the unique microclimate of the room. The block house is made from high quality wood and is superior in characteristics and performance to natural wood. Even after several years the finish looks completely new.

The main advantages of a block house:

- mechanical strength;

- environmental friendliness;

- aesthetic appearance;

- light weight;

- ease of assembly.

The texture of the material resembles natural wood and is highly decorative. From the photo you can evaluate the quality and aesthetics of the block house. For interior decoration, slats with a thickness of no more than 25 mm are suitable. It is not advisable to use thicker lamellas, since increased strength of the timber sheathing will be required. This, in turn, will lead to a decrease in free space in the room. The disadvantages of the material include too low vapor permeability and increased flammability.

When calculating the required amount of material, you should always add 10% to the reserve. If suddenly there are not enough lamellas, you will have to buy more from another batch, which may differ slightly in color. After delivery from the warehouse, the material must sit indoors for two days in order to reach room temperature.

Block house wall decoration

Block house wall decoration Stages of work when finishing a block house:

- the material is mounted on a timber sheathing every 50 cm;

- The distance between the beams is covered with insulation. In this way, heat and sound insulation is maintained;

- individual boards of the block house are easily connected to each other using protrusions located on their surface, this can be seen in the photo;

- The material is coated with varnish on top, which should be renewed periodically.

Clean log house

If desired, you can complete the interior decoration of the house using a clean log frame. This will preserve the natural style of the room, providing a unique aroma of fresh wood. In recent years, this type of finishing has become increasingly popular due to its environmental friendliness, beauty and durability.

A clean log house requires regular maintenance: updating the coating, removing dust and dirt. After five years, additional sanding and varnishing of the surface will be required.

Profiled timber as finishing for a wooden house

Profiled timber as finishing for a wooden house The disadvantages of this type of finish include high flammability and the possibility of rotting. Also, a clean log house will not be able to hide the imperfections of the walls that form over time from moisture, temperature changes and shrinkage.

Plaster

Plaster in wooden houses is suitable only as a decorative coating for some areas. It will be correct to finish with textured types of material.

The advantages of this type of material can be seen in the photo:

- quickly levels surfaces;

- retains its original properties for a long time;

- very resistant to various mechanical influences;

- does not require careful care;

- dirt is not absorbed;

- large palette of colors and textures.

The price of the material in stores is quite high. Moreover, the putty finish needs to be renewed every five years due to the shrinkage of the wooden house. If this doesn’t bother you, then finishing can be done using plaster.

Painting

This option for finishing a private house is suitable for smooth surfaces without any flaws. First you need to carefully sand and tint the surfaces of the walls. Existing small seam defects are hidden with a special cord. It also serves as a thermal insulation element.

By painting the surfaces of a wood home, you can bring out the natural beauty and style. For wall surfaces and ceilings, both colored antiseptic and water-based paint are suitable. Such processing creates aesthetics and allows the base to breathe.

What is good about colored antiseptic:

- protection against fungal diseases and mold;

- preservation of the structure of the wood and the natural texture of the log house;

- aesthetic appearance;

- Natural patterns on the wood stand out, creating a decorative tone.

First, the surfaces are treated with a colorless antiseptic and then covered with a tinting solution. If desired, you can achieve any color intensity. It depends on how many layers you apply. In modern stores you can choose a tinting composition of a wide variety of shades. Types of coatings have different structures - from glossy to silky matte. The choice of coloring, as shown in the photo, will help create an individual style for the room.

Panels

This is a fairly popular type of decoration, helping to emphasize the unique style of the interior. The choice of materials is very large, so everyone can choose them to their taste and for different styles. Modern panels are made from laminated, veneered MDF, which imitates patterns not only of wood, but also of leather, bamboo, and plaster.

What are the benefits of wall panels:

- convenient installation;

- good heat and sound insulation;

- stylish appearance.

Panels are selected according to size in each specific case. First you need to install a fixed timber sheathing. It is very easy to mount the elements; for this purpose, a tongue and groove system is used. After finishing the work, you get a smooth coating without seams, which is suitable for the interior of any room.

Wall decoration with panels

Wall decoration with panels Choosing a floor surface

You should choose a floor covering for a wooden house with special care, because it should be characterized by significant strength and reliability. Natural boards on the floor will emphasize the style of the room and harmoniously complement it. In order to protect the boards from moisture and the effects of pathogenic microorganisms, they are coated with varnish and antiseptic.

Finishing the floor with laminate will decorate the room, creating a unique style. This coating installs very quickly. Laminate looks quite natural, it has the structure of natural wood. It does not require special care and is quite durable.

Laminate as a floor finish

Laminate as a floor finish Experts assure that in a private home it is necessary to use thermal insulation. A special insulating material is laid on the subfloor before finishing. The insulation can be mineral wool, foil insulators or special bulk materials, such as those shown in the photo. Thermal insulation is laid in the gap between the beams. The insulated subfloor should not come into contact with the finish. There must be a gap of at least two centimeters between them.

How to finish a ceiling

The way the ceiling surface is treated is of great importance when decorating a home. Using various materials you can visually enlarge the room, make it more spacious and comfortable.

Coffered finishes are becoming increasingly popular among buyers. Thanks to the combination of wooden beams and decorative inserts, it looks very beautiful and unusual. You can also use painting on the ceiling. This option is more suitable for ethno style.

The ceiling in a wooden building, if desired, can also be finished with clapboard. With its help, a smooth surface is created, and, thanks to the various textures and shades of the material, the completed ceiling will especially stand out against the background of the wall cladding.

Those who prefer a loft or country style interior may not finish the ceiling at all. Natural wood with natural chips, cracks and patterns will look very natural in such interiors, and the pristine beauty of the material will be preserved.

In the presented photo you can see the Scandinavian style of home decoration. It is distinguished by its stylish, laconic design. This style is characterized by the use of natural wooden materials, both for the construction of the building and for its decoration. Such a house will have its own personality.

When finishing the ceiling in a room where it is often humid, the choice of materials should be taken especially seriously. It is not advisable to use only wood in this case, as it may rot over time. In rooms such as the kitchen, bathroom, toilet, it is best to use suspended ceilings. The PVC coating will reliably protect the wood from moisture and steam. It has a varied palette of colors and textures and ultimately looks stylish and in the spirit of the times.

The most suitable ceiling materials:

- tension coverings;

- laminate;

- veneered panels.

How to cover walls

When finishing a wooden house, wall cladding begins after the installation of communications and electrical wiring is completed. First, the surfaces must be checked with a level to make sure they are level. If there are irregularities, it is necessary to mount a frame or lathing for installation. When installing timber sheathing between the slats, you need to leave a space of 40 to 70 centimeters. It is filled with insulating material.

Having secured the insulation, they begin to clean it up. You can use a variety of modern materials for it. Everyone makes their choice of surface based on both their individual preferences and the stylistic decision of the room’s interior, as can be seen in the photo. Paneling and other materials that imitate timber are very popular.

When using lining that imitates timber, the room will acquire an original style, warmth and comfort. Before laying, be sure to make sure that there are no material defects: chips, damage and knots. After laying, the surface is treated with a special putty, sanded, covered with stain and varnish.

When choosing between a matte or glossy finish, experts advise purchasing a semi-matte one.

The fact is that glossy compounds acquire an unpleasant unnatural shine after a short time.

When wondering which finishing material is the best for covering walls, we can say that this is a natural log house. Of course, first you need to sand it, paint it, and then apply an antiseptic or water-based paint to protect the wood from various external damage. Any materials with a natural wooden base are also suitable. Cork is one of the modern stylish materials, but it has a significant drawback - its high price. If money is no object, then cork flooring can be a great option.

Stages of finishing a wooden house from the inside:

- caulk;

- finish the walls in a clean form;

- sheathe the ceiling;

- lay the floor covering;

- treat with stain;

- paint.

Before finishing work, the walls must be treated with fire and bioprotective compounds. They serve to protect wooden surfaces from various external influences: moisture, fire, steam, bugs.

Having decided to build a wooden house, owners often puzzle over how to hide communications in the walls. Since it is impossible to either groove the walls or use concrete screeds, communications are hidden precisely under the finishing coatings. You need to try to choose the finish so that it looks beautiful, stylish, modern and fits perfectly with the intended interior.

A modern wooden house is an excellent choice for comfortable family living. To preserve it for a long time, it is necessary to correctly select and perform interior decoration, maintaining environmental friendliness, naturalness, style and beauty.