Without concrete, there is not a single construction. He has dozens of vocations: to serve people with paths, to lie at the base of the foundation and to take on loads in shopping centers. That's why proper packing and cooking technology is of great importance.

Today there is an increasing need for M400 brands. Concrete M400 belongs to the category of heavy concrete. We will teach you how to prepare and fill it with your own hands, and also tell you about its technical characteristics.

Properties and applications

It is used in areas that are demanding of the absence of external factors. And this is not surprising, because concrete M400 has specifications much higher than that of other brands. Judge for yourself: frost resistance is estimated at 300 points, water resistance - at 10. And in order to inflict significant damage, it will take force 393 kg / cm2.

For understanding, let's compare the different types in the table below:

Table 1 - Comparison of concrete densities

It's not for nothing that concrete with a large specific gravity of just such a brand as the M400 is popular with the construction of bridge structures, army warehouses and parking lots for heavy equipment.

It is irreplaceable in hydraulic structures and in the installation of supporting columns or other structures with increased load on them.

The advantage of this grade of concrete at the same time is its drawback. It is appreciated for the rapid grasp and acceleration of the work process. But at the same time, the speed factor limits the distance for transportation. The frozen concrete turns into a solid block. In it, you can not make a hole, drive a nail or make a corrective repair. This circumstance explains the rarity of the use of M400 concrete in private construction.

The bulk of heavy concrete is produced automatically. The operator sets the temporary program. As the concrete is made, it becomes a homogeneous mass. Manually, it is rarely possible to reach such an indicator because of distractions. But, if you try, this result is possible.

Composition, proportions, parameters

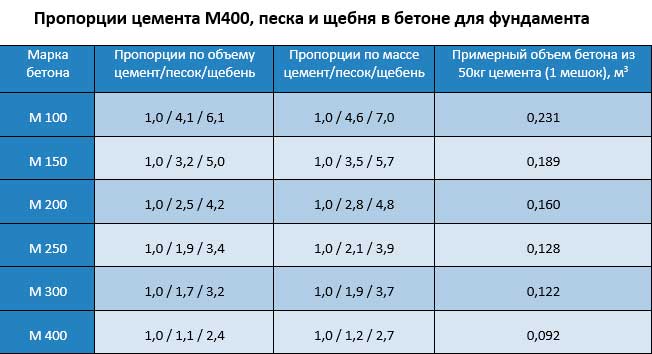

Quality concrete will be obtained only on condition of strict adherence to its preparation technology and recommendations on composition. The recipe depends on the purpose and the desired strength.

Note that when preparing concrete M400 it is necessary to use cement of the same category or higher. This is important, since the density of smaller grades results in a weak specific gravity, which will lead to over-consumption of components. Below we will consider the proportions necessary for the production of concrete grade M400.

Table 2 - Concrete M400 from cement, sand and gravel. Proportions.

Table 3 - Technical characteristics and composition of concrete m400 per 1m3 (base cement M500)

Now we will prepare the concrete with our own hands from the material of the brand M400. Consider the definition formulas the required quantity, the nuances of cooking and creating a cover with your own hands. In particular, let's touch the base under the house from the tapes, foundation slabs and columnar shape. Let's talk about the features of the pile-ramming structures and give recommendations on pouring the floor.

It should also take into account the presence of moisture in the sand. It should either be dried to zero moisture or reduce the volume of water by several percent. And before starting work, sand should be cleaned, thereby increasing the graspability of concrete.

The ideal consistency of concrete - when it does not drain off the shovels very quickly. Stirring should be felt. It is better to fill the basement in the warm season. Otherwise, you will have to spend additional efforts on creating drainage, heating the water and fighting the setting of concrete.

Belt formula

On the eve of cooking it is important to correctly calculate the required volume of concrete. For this purpose, the number of tapes to be filled is determined. Then the parameters of each of them are multiplied. For convenience of calculation, the length, width and height of each tape are converted into meters. Each tape is calculated separately, and then their results are summed up!

Here it is important to consider one feature. In volume calculations, angles are involved twice. This second "virtual" corner serves as an insurance parameter. Concrete must be prepared with a margin for an unforeseen event.

Fill ribbon foundation occurs slowly, layer by layer. The height of one layer is 25 cm: for the foundation of a meter height, 4 layers are required. Each layer is aligned with the help of the board, and also stamped with a hammer or vibrator.

At the final stage, from ready-made foundation release air. To do this, every 3 to 3 meters, the reinforcement is stuck into it. But due to the fast grasp and the severity of the design of the m400, it's quite difficult to do this.

Foundation plates

Fill plate foundation much different from the filling of tape. The amount of concrete required is determined by multiplying the plate parameters. Since the plate is integral, it is required to fill the entire material at once.

But the main feature is the rammer. It is carried out throughout the area of the construction every half a meter. Alignment of the plate is carried out, moving from the smaller edge of the perimeter towards the opposite, moving the snake. It is most convenient to carry out the operation with a board with a handle. Also, you can not do without puncturing the concrete with a fitting to let out excess air bubbles.

The column foundation is filled in the same way.

Pile-packed foundation

Here it is necessary to take into account the change in the calculation formula. If earlier we calculated the volume by the formula of a parallelepiped or a cube, now we are dealing with cylinders. The radius of the pile's circle is squared, multiplied by the height, and then by the Archimedean number equal to 3.14. To the received value it is possible to add 10-15% of an insurance stock.

The volume of concrete is calculated for each pillar separately. Pouring occurs in the same way as in other cases - layerwise with tapping and puncturing the basement. In view of the fast graspability of concrete of the grade m400, it is desirable to carry out the work together with assistants.

Floor

In the end, let's talk about m400. Talking about the fill, we assume that all the preliminary work - insulation, reinforcement, etc. already implemented. Let's start by calculating the required amount of concrete.

The volume of concrete is calculated by the product of the floor area by the thickness of the screed. Then the resulting value is multiplied by the consumption factor 1.02.

Now, using the table of proportions and the proportion of concrete components above, determine the required amount of consumables: sand, gravel, cement and water. We proceed to the preparation of the mixture, based on the above advice on the proportions.

The floor must be filled immediately. It is mandatory to use level beacons that allow you to perform work not only qualitatively, but also smoothly. Accurate flooring is important not only in residential buildings, but also in industrial buildings where the floor is exposed to loads from equipment and machinery. In addition, the unevenness of the floor will complicate its operation.

Conclusion

Today we examined all aspects of heavy concrete. I would like to give only one recommendation at a last: expect work with this concrete so that you do not distract anything, and also keep the recipe - the accuracy of proportions is important. You will be rewarded with a reliable home, which for many years will not be afraid of external influences.

Concrete in 30 m400 - a building material, as the main components of which are used inorganic substances. This type of concrete is obtained with cementitious constituents of cement, fillers and additives. Ingredients included in the composition, allow to give a solution of b30 m400 necessary properties (strength, frost resistance, moisture resistance). Concrete is used in the construction of structures operated in difficult conditions. It is important to strictly follow the prescribed design standards, requirements for work. Today, the brand b30 is used more widely than five years ago. Such popularity of the brand can be explained by the strengthening of state control over the construction industry.

Concrete solution б30 - a heavy kind of building materials. Its reliability, durability, frost resistance have high indicators, which allows the use of solutions in 30 for the construction of facilities, which are subject to special technical and regulatory requirements. To use concrete solution builders should be aware of its characteristics. M400 - concrete of class b30. The mixture has a waterproof class W6-W12. With moisture resistance W6, the density of heavy concrete is 2,430 kilograms per cubic meter. The frost-resistance of the material is F100-F300, the mobility reaches P3-P5.

Composition and proportions

Before preparing the mixture, you need to read the state standard, which indicates the proportions of components. Only by following the instructions, you will be able to make a solution of the required density. The cement mortar M400 with frost resistance F300 includes ingredients in the following proportions (kilograms per cubic meter):

Before preparing the mixture, you need to read the state standard, which indicates the proportions of components. Only by following the instructions, you will be able to make a solution of the required density. The cement mortar M400 with frost resistance F300 includes ingredients in the following proportions (kilograms per cubic meter):

- three hundred ninety-five kilograms of cement;

- eight hundred and seventy kilograms of sand;

- one thousand seventy-five kilograms of rubble;

- one hundred and seventy liters of water;

- seven and a half kilograms of plasticizer.

Application

This building material is used for works:

- the construction of bridges designed for greater loads and intended for the use of large traffic flows;

- construction of bridges for railways;

- the manufacture of storage facilities for banks, columns, archways and others;

- production of spans of staircases, curbs, etc .;

- devices of dams and other similar structures;

- creation of collectors for communication;

- erection of facilities for the energy, mining and machine-building industries.

The need for such a concrete arises when laying slabs for pavements, floors, sewerage, laying the top layers of the pavement with large loads of slabs. This type of concrete mortar (В30) is used for erecting objects that are strongly affected by nearby railways, subways, highways.

Production features

It must be taken into account that the manufacturing process is almost identical for any kind of concrete, but it is possible to make a solution of the correct consistency only if the technology is observed. The slightest violation can lead to a decrease in properties. The correct ratio of ingredients will help you make high-quality cement b30 m400. When choosing a cement mix, you need to make sure that it did not have time to absorb moisture during storage and released a maximum of three months. back. In addition, an important feature of the manufacture of concrete is the selection of good materials. After acquiring components, builders start work. The preparation of the mixture consists of several steps:

It must be taken into account that the manufacturing process is almost identical for any kind of concrete, but it is possible to make a solution of the correct consistency only if the technology is observed. The slightest violation can lead to a decrease in properties. The correct ratio of ingredients will help you make high-quality cement b30 m400. When choosing a cement mix, you need to make sure that it did not have time to absorb moisture during storage and released a maximum of three months. back. In addition, an important feature of the manufacture of concrete is the selection of good materials. After acquiring components, builders start work. The preparation of the mixture consists of several steps:

- First mix the sand, cement slurry to a uniform state.

- Then add water. The strength of the structure depends on the amount of water. To make one cubic meter, you need a lot of liters of liquid.

- After that, the crushed rock is added to the mixture and mixed thoroughly.

Cost

The high cost of concrete is explained by many advantages. Today it is about 60 dollars per one cubic meter. This building material in its economy refers to the middle category. It is sold in the form of a ready-made solution, the mobility of which reaches three to five points. The mixture is sold in most specialized stores for builders. The solution can be found in production points, in factories that produce products, constructions from cement.

Experts advise to cooperate with reliable suppliers of building materials, since it is visually difficult to determine the type of mixture. To get high-quality concrete, you need to adhere exactly to the technology and recommendations of compliance with the formula, the ratio of components.

Concrete m300 is one of the most commonly used concrete grades that is used in the construction of belt, pile-and-mortar and other types of foundations. And also, concrete is necessary for the construction of ribbon fences, retaining structures, road surfaces, trawl tiles, etc.

This concrete can be bought as a ready-made mixture or prepared independently. In any case, to the ingredients that are part of the concrete m300, there are certain requirements, which we now disassemble.

Basic components of concrete m300

- Cement M-400 or M-500 acts as the main fastening element. Depending on which brand of cement is used, the amount of other materials may differ (see the proportions below).

- Crushed stone. The composition of concrete m300 is used crushed stone different sizes from 5 to 70 mm (rarely 150 mm). Lime or granite crushed stone will do. Gravel is used very rarely, since it can contain harmful impurities.

- Sand. For the manufacture of concrete, sand must necessarily have a high density - not less than 1.8 kg / cubic meter. This material can be natural or artificial, and its particles should have a certain calibration - 0.15-5 mm.

- Water - the last ingredient in the concrete m300. You can use both natural and tap water without impurities, preventing the hardening of concrete.

- Cement brand M-400 or M-500.

The main requirement for concrete brand M300 is uniformity. It is this indicator that should be carefully monitored at every stage of production.

Technical characteristics of concrete M300

- class - B22.5;

- mobility of the mixture - P2-P4 (depends on the requirements imposed on the object);

- water resistance - W6 (moisture will not be absorbed in significant amounts).

- frost resistance F200;

- strength 295 kgf / cm 2;

- rigidity - Ж2-Ж4.

The proportion of concrete m300

As a rule, the main requirements for concrete are high frost resistance and moisture resistance. These characteristics are concrete grade m300 . In addition, it quickly hardens and is resistant to significant loads.

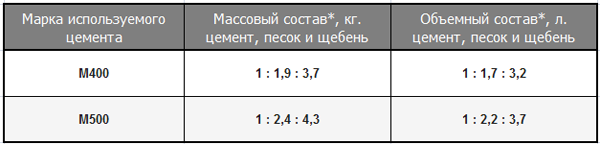

As we have already said, cement M-400 or M-500 is used for its production, and the proportions of concrete vary:

- In the event that cement M-400 is used for the preparation of concrete, take in proportions of 1 kg of cement - 3.7 kg of crushed stone and 1.9 kg of sand. When calculating in liters: for 10 liters of cement we take 17 liters of sand and 32 liters of rubble. When mixing the components in this quantity, 41 liters of ready-mixed concrete are obtained at the output.

- If you use cement M-500, the composition of concrete m300 will differ in its proportions. In this case, to 1 kg of cement, it is necessary to add 2.4 kg of sand and 4.3 kg of crushed stone. Accordingly, out of 10 liters cement, 37 liters of rubble and 22 liters of sand, as a result, 47 liters of concrete m300.

If you know these recipe data, calculating the necessary amount of materials and funds for their purchase will not be difficult for you.

The whole process of calculating and mixing concrete m300

It can be confidently asserted that no serious construction can not do without concrete work. This material is used almost everywhere due to the highest properties of strength and durability. In addition, the cost of the composition itself is much less than any modern version with similar physical properties. To better navigate the properties of concrete, depending on the proportions of components, it is assigned a particular brand.

Overview of the main brands

To better understand, consider which main brands are used in construction and their main differences.

| M100 | This option is suitable as a lower layer for foundations and foundations, as a stand-alone material is not suitable. |

| M150 | It is also often used as the first layer for pouring more durable grades, but can be used as the basic material of the foundation for the foundation. |

| M200 | The most popular option in private construction, from it are made both plinths and screeds in the premises. |

| M300 | Applicable in cases where additional strength is required (large building weight, complex system design, unstable soils). |

| M400 | It is used rarely and only where special strength and durability is required: bridge structures, beam supports and bearing elements subjected to high loads. This brand is also used in the construction of bank vaults. |

As you can see, the technical characteristics of the M400 concrete are among the highest among all, for this reason it is used less often than other brands. But recently, when the requirements for strength and durability have increased significantly, the composition of the brand in question is used much more often.

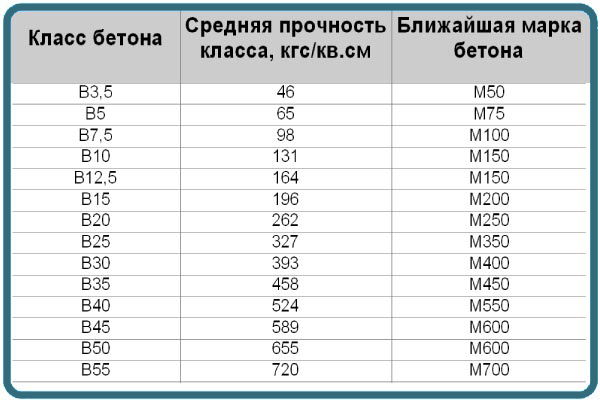

It is easy to see that the proportions of cement M400 for concrete ultimately allow you to save your time and money. It is worth noting that all brands are divided into classes, each of which has its own, you can familiarize with which you can in the presented table.

Advice!

It is very important to order concrete in serious companies that have been working in the market for a long time.

Since it is impossible to determine the brand, some unscrupulous producers make a poor-quality solution.

Overview of the main properties of concrete M400

As noted above, the brand of concrete M400 is much more common in industrial construction than in private construction, and the reason for this is several key factors:

- The most important reason is the too high properties of M400 concrete. Of course, it can be used, but the expediency of this solution is very doubtful, since for structures of small structures the density of M400 concrete is very high. Therefore, based on practicality, it is better to use lower grades, although sometimes this option is justified.

- The second important factor is the high price of this option, since M400 concrete contains a lot of cement, which is the most expensive component. At considerable volumes, the cost of the project increases quite noticeably, although there is likely to be no noticeable difference.

- The concrete of the brand in question grasps much faster, which can create certain problems in the process of work. The main reason is that the M400 concrete per 1m3 contains twice as much cement as the M200 grade. On the one hand, it's very good, but on the other hand, if you need to transport the solution to a long distance or the workflow is slow, the composition can begin to set.

- Another important factor limiting the use of the M400 brand in private building is the complexity of its production by one's own hands. At first glance, the instructions for preparing the solution are simple enough, but do not forget that to ensure the highest properties, a small amount of water is required, but it is very difficult to mix the consistency of such a consistency.

- The main scope of this concrete brand is the construction of foundations for large, massive objects. But this is not the only sphere of its use, it is perfectly suitable for the manufacture of stairwells, columns and supports. In addition, the M400 grade is often used for work on sites that will later be subjected to high loads.

Features of the formulation

It is worth noting that this process is basically the same for all brands, but still it is possible to achieve high quality of concrete, only by observing all the requirements of the technology. Any violation leads to a decrease in performance.

The correct proportions of the main components

Consider what components should be used, and in what proportions.

To make everything clear, consider the composition of 1 cube of concrete M400:

- High-quality building sand without impregnations in the form of silty sediments or chernozem. It is important that it is clean, the ideal option - washed river sand, for cooking you need 540 kilograms or 360 liters, if you use cement M400, and 720 kilograms or 480 liters, if you have cement M500.

- Another important component is crushed stone, a variant of dense rocks with a strength index of at least 1,100 units is suitable. Optimal fraction of crushed stone - from 5 to 20 millimeters, too small, as too large fragments negatively affect the strength of concrete. If you use cement M400, you need 1215 kilograms of crushed stone (or 736 liters), and if you use the brand M500, then 1440 kilograms (in liters this value is 873 liters).

The better the cement, the stronger the concrete, remember this simple truth

Important!

When purchasing cement, make sure that it was produced no more than 3 months ago and was not saturated with moisture during storage.

Well, do not forget that the specific gravity of M400 concrete is much larger than, for example, water, but this is below.

How is concrete prepared?

After collecting all the main components, you can start mixing them, the process is as follows:

- First, sand and cement are mixed, this is done until the mixture becomes completely homogeneous.

- Further, water is added, the strength of the composition largely depends on it, therefore mistakes are inadmissible. To prepare 1 meter of cubic, 225 liters of water are used.

The weight of the concrete cube M400 is 2430 kilograms

Conclusion

Based on all the above facts, it can be concluded that the concrete of the M400 grade is suitable for the most critical objects under high loads. Even based on how much the cube of concrete M400 weighs, we can conclude that this material It has a high density and is able to withstand the highest loads. The video in this article will describe some of the issues discussed in the article in more detail.

Concrete is a building material obtained by mixing a binder, filler, plasticizer and water and possessing the properties of a stone after solidification. A typical area of application of concrete is the production of a substrate serving as a support for the foundation.

The application of this mixture dictates the requirements for its characteristics, among which the most important is the index of compressive strength or guaranteed withstand load. The need to ensure the strength characteristics of the material causes a strict regulation of the quality of each component of the composition of this building material.

It should be noted that there are approximate proportions of parts of the composition of the mixture, the exact observance of which provides a given compressive strength, and, consequently, the stability of the structure constructed on it.

Features of concrete mixes

The materials included in the solution provide the ability to maintain plasticity when working with it for the time necessary to give it the necessary flatness indices.

The speed of its congealing depends on:

- the size of the factions included in its composition,

- the amount of water in solution,

- ambient temperature,

- brands and varieties of cement,

- thickness of the layer to be laid,

- humidity of the components of the mixture and air.

The time necessary for complete solidification to the state of the stone and the acquisition of the necessary strength characteristics by them is 4 weeks. To the characteristic features of this building material refers to the gradual acquisition of strength characteristics.

So, to achieve the optimum strength values of concrete should pass at least six months, and the maximum values of this parameter are achieved after a year.

The main conditions for the qualitative hardening of concrete are:

- Providing the temperature in the optimum range of values of 18-22 ° C, at higher dewatering, a decrease in this index leads to a slowdown in hydration and an increase in the setting time of the mixture.

- Humidity of the environment should be at least 90%, and in a medium with high values of this index, the process of solidification of the solution is accelerated while ensuring the necessary characteristics. During the summer, during the holding of concrete, it is necessary to monitor the maintenance of the necessary humidity, by periodically wetting the substrate.

During the formation of a solid structure, this material passes through the setting and solidification phases.

At the time of setting, the brand of concrete is affected, for example:

- M200 hardens for 2-4 weeks, and grasps for 2.5 hours;

- M400 to achieve the necessary strength values, an exposure of one to two weeks is necessary, and the time required for setting is 1-2 hours.

The mixture must have some fluidity, since in the process of working with it and performing tamping, it is necessary to eliminate all air voids from it. With the aim of eliminating air voids from the solution, vibration is used, which, when making the foundation and walls of structures, uses a hose that creates oscillations. Elimination of air occurs when it is connected to the drive and immersed in concrete.

When using reinforcing elements, it is recommended to pierce concrete to the full depth, performed by a sharpened part of the rod. Thus, air voids, located both in the reinforcement mesh, and those remaining in the mixture itself are eliminated.

In the manufacture of thin structures, such as screeds, the elimination of air voids from it is carried out with the aid of an assembly with a removed rod. The working organ perceives the vibrations coming from the drive, when it moves along the processed plane, simultaneous condensation and elimination of air voids occurs.

For a mixture of any brand, the general characteristics are that it is a mass having a non-uniform consistency. To achieve a homogeneous structure, the solution is densified, thereby ensuring a high density of contact between the individual particles.

Marking of concrete

The main difference between concrete grades is the quantitative ratio of the components of the mixture. It is on him that the resistance to the action of deforming loads depends. In addition, the strength characteristics of the building material is due to the dispersity of the constituent components of the solution.

There are several options for marking the mixture:

- Deprecated mixtures containing a certain amount of components of cement, sand and crushed stone are designated with the letter M. The figure indicated after this means the compressive strength expressed in kgf / cm 2, which corresponds to 0.1 MPa. All types of concrete according to this classification are located in the range of M50-M1000.

At present, this building material is marked with the letter B with further indication of the figures that indicate the guaranteed strength which the mixture expressed in MPa is capable of providing. Existing classes of concrete are designated from B 3.5 to B 80.

Below is the correspondence between the brands of the building material using the old and new designations:

The marking stipulated by GOST specifies in addition to indicating the compressive strength, through a hyphen, to designate the amount of impurities that can fluctuate from 0 to 20%.

The difference between concrete grades is a variety of used cement (M 300-M500), sizes of fractions of sand and crushed stone. For example, when using 1 part of cement M 400, 4 crushed stone, 2 sand, concrete M250 (B20) is obtained. The amount of water is half the norm of cement. When using the same proportions for cement M 500, a mixture with the marking M 350 (B25) is obtained.

Areas of use

Concrete is a universal material that is used at every stage of construction, from foundation to roofing. The principle used in the construction of a concrete base is that before applying the main part of the concrete, it is necessary to make a substrate under it.

For this you can use the building material brand B7.5, It has a lower strength in relation to the basic grade and allows the use of coarse sand particles.

Marks that have a small number after the letter M, for example M 100 are used for the device of linings for the basic volume of a building material, a construction of borders and paths.

For the construction of a garage, slabs for which there is a small load, the construction of utility rooms, is used M 200.

M 300 is made for the construction of a strip foundation, arrangement of sites and fences.

M 400 characterized by high strength, short setting time and a relatively high price, because of this, its use in individual construction is considered inexpedient.

Concrete of higher grades has a higher density and mass and is used for the most part to build industrial structures. As part of the construction of civilian objects, the most common types of construction materials such as M 300-M500.

Components of concrete mixes

The choice of a suitable brand of concrete begins with the determination of the volume of the structure or foundation and the nature of the existing loads. The selected brand of concrete contains cement, crushed stone and sand, mixed in a ratio providing the required strength characteristics.

In addition, plasticizers, anticorrosive additives, accelerators, strength enhancers can be present in the building material.

To each of the components of the mixture, the requirements are imposed, designed to ensure the strength characteristics of the material:

- Cement should be dry, crushed to as small as possible fractions, not contain the breast. To avoid the formation of lumps, it is necessary to ensure a certain humidity of the room in which the cement is stored. The most popular is the use in the preparation of a mixture of portland cement, which is characterized by a high content of calcium silicates. Due to this, it is possible to achieve good adhesion characteristics and connection of the individual particle components in a monolithic integral structure.

- Sand, when used in the preparation of concrete, it is necessary to prefer the river variety. The sizes of fractions can vary from 1.5 to 5 mm, the content of foreign impurities is unacceptable.

- Gravel (crushed stone) should have dimensions in the range of 8-35 mm, and a larger size of the fractions contributes to the increase in the strength of concrete. For, it is recommended to use crushed stone with a size of fraction 20-35 mm, it is important to ensure an even distribution of the material for better adhesion of particles among themselves.

- Water should be cleaned, since in the presence of certain types of microorganisms and additives in it, deterioration of strength characteristics is possible. In addition, it is forbidden to use river water for preparing concrete, when choosing water, the criterion of correctness is the possibility of human consumption.

- Plasticizers, provide mobility of the mixture and protect it from the formation of cracks.

- Anticorrosive additives Used in the case of reinforcement to prevent oxidation.

- Accelerators, Used to reduce the setting time and setting of concrete components. Used in the case of limited limits on the construction of facilities.

Proportions when kneading concrete

The amount of each of the components of the mixture can be calculated by taking as a basis one part of the cement or selecting from the tables, focusing on the yield of a mixture of 10 liters of cementing substance.

The latter method can be used when using a large amount of concrete. Optimal for the preparation of the foundation is a composition comprising one part of cement, 2.5 sand, 4.5 crushed stone.

If it is necessary to construct the steps, fill the garden utensils and perform the decoration on the site, a solution based on a fine fraction of crushed stone can be used. In this case, a composition of one part of cement, 3 sand and 6 rubble with a size of 0.3-3.5 cm can be used.

M400

The mark is obtained by mixing 10 kg of cement, with 12 kg of sand with a low dispersion and 27 kg of gravel. The scope of this brand is the laying of foundations for multi-storey buildings, the construction of walls and the provision of coverage on sites with high demands on strength.

M500

The brand contains a large amount of cement, which determines the high strength of the mixture and the area of its application. M 500 is used in the construction of hydraulic structures and special purpose facilities. The ratio of components in the preparation of the mixture is 1: 1.2: 2.5.

The benchmark for calculating the components of the mixture is the cement brand and its quantity in the solution. In this case, the amount of water is selected based on the intended use of the material from the range of 0.5-1 h.

To accurately measure the portions of each component, it is necessary to weigh the same volumes of each component. To do this, the measuring container without compaction is alternately filled with each material with the weighing of each portion. Using calculations, the preliminary values are converted to the volume of buckets used.

Preparation of concrete mix by hand

The mortar can be made by means of a concrete mixer in the case of large-scale construction or prepared manually when using a mixture in an individual farm.

In the latter case, two options are possible:

- Separate mixing of sand and cement in a dry form with the further addition of water. This ensures a high uniformity of the composition, however, with the addition of water, a long-term or poor-quality blotting of the mixture is possible. At the bottom of the container, components that remain unaffected with mixing may remain, which leads to a violation of the proportions and a deterioration in the strength characteristics of the solution. In the case of prolonged mixing, much time is expended, as a result of which setting and stratification of the composition can occur.